Energy Storage Systems Boost EV Fast-Charger Infrastructure (Part 1)

Electric vehicles (EVs) will gain more and more market share, eventually taking over internal-combustion-engine vehicles. Direct-current (dc) fast-charging stations will replace, or integrate with, petrol stations, and renewable energies like solar and wind will be used to power them. People will want to charge their EVs in less than 15 minutes and they won’t want to wait in a queue for a unique charger.

Considering multiple charging points, the peak power required can be more than 1 MW. This could lead to grid collapse in many points or require huge investments to improve the transmission lines and central power plants needed to supply a much higher base load. This fluctuating demand must be merged with the intermittent energy generated by renewable sources such as solar and wind.

Energy storage systems can solve this problem in a simple and elegant way, using fluids or gasses to store energy, releasing it when needed (for example, when fueling a car). With the same principle, we can store electric energy in batteries to boost an EV charge to keep the grid stable by shaving the peaks of power or to provide supply in case of blackout.

The mobility market is changing. Nearly 3 million EVs will be sold in the year 2020, from a total of more than 80 million vehicles. While this can look like a niche market, the forecasts are for a booming growth of up to 10 million EVs sold in 2025 and more than 50 million in 2040, from a total of 100 million. This means, by the year 2040, 50% of sold vehicles will be fully electric. All of these vehicles need to be charged.

Together with the rising EV market, we see that the renewable-energy generation market—which has recently experienced a boom in solar photovoltaic (PV) systems—is still growing at a good rate, thanks to a price reduction of about 80% in the last 10 years and the push to decarbonize. Representing less than 5% of today’s global electricity generation, solar is expected to be more than one-third (33%) of global electricity generation in 2050.

With a future made of intermittent loads, the EVs that need to be charged, and intermittent energy sources—PV, as well as wind generation—present challenges in combining these new players in the energy ecosystem, centered on the grid. Intermittent loads such as EVs will require extra dimensioning of the transmission lines to cover the higher power peak demands.

Integrating Green Energy

Solar production will change the way that central power plants operate, making sure the grid isn’t overcharged and that people will have easier access to electricity. More and more self-usage of electricity will be produced at home with residential solar systems. To make all entities work together smoothly as well as benefit from the renewable sources and zero-emission EVs, energy storage systems must come into the game to ensure we can store and reuse the electrical energy that’s generated when demand is low (for example, solar energy generated at noon to be used in the evening) to balance the grid.

Energy storage systems (ESS) are the electrical equivalent of tanks for fuel or storage warehouses for coal. ESS can be used in multiple applications on both residential and industrial scale.

In a residential application, it’s simple to connect the PV inverter to the storage battery, to save and use the energy in the house or to charge the car overnight with the energy produced by the sun during the day. In an industrial- or utility-scale implementation, such as grid-connected services, ESS installations can be used for different purposes: from regulation of PV and wind sources to energy arbitrage, from backup support to black start (removing diesel generators), and, most importantly from a total cost point of view, investment deferral.

In this last case, ESS will be used to cover power peaks in the nodes of the grid, making sure the existing transmission lines don’t need expensive upgrades. Another relevant user case is the off-grid installation, where ESS enables microgrids or islands to be self-sufficient. The ESS market, considering all of its possible applications, will breach the 1000-GW power/2000-GWh capacity threshold before the year 2045, growing fast from today’s 10-GW power/20-GWh capacity. For this article, the focus will be on ESS installations for the EV charging infrastructure (Fig. 1).

Charging Infrastructures

The ac charging infrastructure, for both private and public installations, is simple but power-limited. Level 1 ac chargers work at 120 V ac, delivering 2 kW maximum; level 2 is capable of 240 V ac and 20 kW. The power conversion from ac to dc is, for both, required to the vehicle on-board charger. The ac wall box is more for metering and protection than charging. The vehicle on-board charger is usually rated lower than 20 kW, for cost, size, and weight limitations.

On the other hand, dc charging enables the possibility to use much higher power: level 3 chargers are rated up to 450 V dc and 150 kW, and the latest super chargers (equivalent to a level 4) can go beyond 350 kW and 800 V dc. The upper voltage limit is set to 1000 V dc for safety reasons when the output connector is plugged into the vehicle.

While using a dc charger, the power conversion is made in the charger, and the dc power output directly connects to the car’s battery. This removes the necessity of an on-board charger, with the added benefits of reduced space and weight.

Nevertheless, in this transition phase, when the EV charging infrastructure is still fragmented and different from country to country and region to region, a small 11-kW on-board charger is usually standard in electric cars. This gives users the ability to charge via an ac outlet if needed. Increasing the charging power requires a higher operating voltage to make sure the current is kept within reasonable limits for the cable’s size and cost. It also implies the need to properly design and dimension the local grid where the charging stations are installed.

Let’s imagine a charging station of the future (in the year 2030) where the fuel consists of electrons and it’s available from a pipe called a transmission line, connected to the medium voltage (MV) grid via a transformer. Today the fuel is stored in big tanks underground and brought to the fuel station regularly by tank trucks. Having the new fuel—the electrons—always available from the grid seems to be an easy and issue-free solution. However, we can see that this simple approach isn’t sustainable if we want to give drivers the possibility to charge their EVs in less than 15 minutes.

In this example, our charging station has five dc charging points, each capable of maximum 500-kW peak power output. The worst case, for which the charging station must be dimensioned, is represented by five EVs charging fully depleted batteries at the same time. To simplify the calculation, we now consider zero losses in the power-conversion stages and in the battery charging path. Later, we will see how a proper design is influenced even by small power losses across the power chain.

Let’s consider five EVs, each one with a 75-kWh battery (the cars available in the market today, with a full electric powertrain, have batteries from 30 to 120 kWh) that needs to be charged from 10% state of charge (SOC) to 80%:

This means that an energy of 262.5 kWh must be transferred from the grid to the EVs in 15 minutes:

Slightly more than 1 MW of power must be provided by the grid to the EVs, for 15 minutes. The charging process of lithium batteries will require a constant-current, constant-voltage charging profile, where the power required to charge up to 80% of the battery is bigger than the last 20%. In our example, we stop the charge at 80%, assuming maximum power.

Peak Management

The sub-grid where the charging station is located must sustain peaks greater than 1 MW intermittently. Very efficient and complex active power-factor-correction (PFC) stages must be implemented to make sure the grid is kept efficient, without affecting the frequency or creating instability.

That also means installation of very expensive transformers to link the low-voltage charging station to the medium-voltage grid, as well as making sure the transmission lines bringing the power from the power plant to the charging station are properly dimensioned to cope with the peak power required. If the charging station is charging a mix of cars and trucks or buses, the required power is higher.

The simplest and most economical solution, instead of installing new transmission lines and big transformers, is to use the power locally generated by renewable sources, such as solar and wind. This enables users to have a direct link to the charging station with extra power and not rely only on the grid. Realistically, solar PV installations in the range of 100 to 500 kW can be done at the charging station or near the sub-grid where the charging station is connected.

While the PV source can provide 500 kW, limiting the power requested from the grid down to 500 kW, the PV source is intermittent and not always present. This brings instability in the grid, as well as enabling the EV drivers to charge their cars at the fastest speed only when the sun is shining at its maximum. It’s not what the users want, and it’s not sustainable.

The missing piece of this power electronics puzzle is the ESS. Acting like the underground tank for the fuel in today’s stations, the ESS can be represented as a big battery capable of storing and delivering energy from the renewable sources to the grid or to the charging piles and back into the grid. The first key characteristic of the energy storage unit is being bidirectional and working on the low-voltage side of the grid.

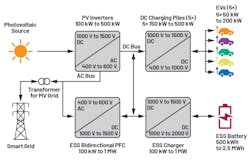

The new installations will target a dc bus voltage of 1500 V dc, linking the renewable sources, the EV charging stations, and the ESS battery (Fig. 2). A proper sizing of the ESS must be done to make sure the balance between peak power and energy capacity is optimal for the specific installation.

Such a ratio strongly depends on the size of the local power generation, being through solar, wind, or other sources, the number of charging piles, other loads connected to the sub-grid, and the efficiency of the power-conversion systems. In this calculation, the energy storage system should have a capacity between 500 kWh to 2.5 MWh and a peak power capability up to 2 MW.

In Part 2, we will analyze the critical components of the electric-vehicle dc fast charging infrastructure and how to address the specific challenges that arise.

Stefano Gallinaro is Strategic Marketing Manager at Analog Devices Inc.