Energy Storage Systems Boost EV Fast-Charger Infrastructure (Part 2)

What you'll learn:

- Silicon-carbide (SiC) MOSFETs help deliver high power-conversion efficiency.

- An isolated gate driver/power-supply controller design best meets energy-storage-system requirements.

- A reliable and precise battery-management system extends lifetime by 30%, thus saving costs.

Part 1 discussed the role of energy storage systems (ESS) in dc fast-charging systems and defined the critical components of the charging station—the sources, the loads, the energy buffer. Now, as discussed in this article, an analysis must be done for the four power-conversion systems that create the energy paths in the station.

The four power-conversion systems are all sitting on the main dc bus, rated 1000 to 1500 V dc. The higher the required power, the higher the dc bus voltage. The industry standard today and for the next 20 years is and will be 1500 V dc. While going at higher voltages is possible, this brings complications for the safety regulations, power components, and system designs, making it inefficient with the available technologies. That’s not to say that in 10 years new technologies, such as power switches and protection systems, won’t make it possible to move to 2000 V dc or higher.

Considering the PV inverter, we see that it has a double function of a dc-dc converter—for the power path going from the PV panels to the dc bus; and the function of a dc-ac inverter—for the power path going from the PV panels to the ac bus and then into the grid. The dc-dc conversion stage is the most important here, since the ac-dc stage can also be integrated into the main bidirectional power-factor-correction (PFC) inverter going from the dc bus to the ac grid.

From IGBTs to SiC MOSFETs

Considering state-of-the-art power electronics designs, the highest efficiency is reached with converters designed around silicon-carbide (SiC) power MOSFETs. The comparison with silicon insulated gate bipolar transistors (IGBTs) shows an efficiency increase in the range of 5% (maximum load) to 20% (partial load). In our example, with a PV inverter rated 500 kW, 5% better efficiency means 25 kW less losses or higher power output. It’s the equivalent of five houses’ consumption or a big heat pump generating hot water or cooling the charging-station building in the summer.

A very similar calculation can be made for both the dc charging piles and the ESS chargers. In both cases, two design approaches are possible: either big monolithic power converters rated more than 100 kW, or many small converters rated 25 to 50 kW, used in parallel. Both solutions have benefits and drawbacks. Nowadays, the multiple connections of small converters are leading the market because of lower costs due to economy scale and simplicity of design. Of course, a smart energy-management system must be adopted.

Even for these dc-dc converters, moving from silicon IGBTs to SiC MOSFETs is bringing tremendous efficiency benefits, together with space and weight savings, at the cost of a slightly higher price. Today, cost is 25% higher, expected to drop to 5% in the next five years. The efficiency gains alone can override this small price by saving (if we use the same 5% at maximum load):

Finally, in the PFC inverter, 5% of 1 MW is again 50 kW, bringing the total power savings, just because of higher efficiency of SiC versus IGBT, to 250 kW. This is like having an additional charging pile or the possibility to better balance the energy consumption overtime versus the actual demand of loads.

To achieve these results, as we said, SiC MOSFETs are needed, but they can’t solve the issues alone. How SiC MOSFETs are driven is key to reach the required switching frequency needed to achieve the best tradeoff between system design costs (driven by the MOSFETs, the coils, and the inductors) and efficiency. Designers target the switching frequency in the range of 50 to 250 kHz. The requirements for the gate drivers are becoming more challenging, though, mainly in terms of shorter propagation delays and improved short-circuit protection.

Isolated Gate Driver

To meet these requirements, an isolated gate driver like the ADuM4136 from Analog Devices enables a common-mode transient immunity (CMTI) of 150 kV/µs to drive the SiC MOSFETs in the hundreds of kilohertz switching frequency range. This, together with fast fault management like the desaturation protection, gives designers the possibility to properly drive single or parallel SiC MOSFETs up to 1200 V.

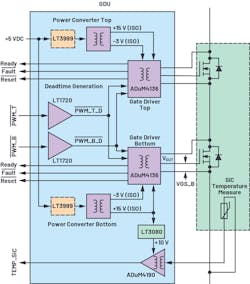

The isolated gate driver must be powered. This can be accomplished, for example, using a combination of the ADuM4136 gate driver with an LT3999 push-pull controller to create a noise-free, high-efficiency building block to properly manage SiC MOSFETs (see figure). The LT3999 is used to control a bipolar isolated power supply for the ADuM4136. The ultra-low EMI noise design of the LT3999 isolated power supply, together with the possibility to switch up to 1 MHz, enable a compact and cost-effective approach to achieving this goal.

The total propagation delay, including the dead time plus the propagation delay, is 226 ns for turn-on and 90 ns for turn-off. The driver delay times are 66 ns for the turn-on and 68 ns for the turn-off, while the dead times are 160 ns for turn-on and 22 ns for turn-off.

The goal of having very high power density in the power converters is achieved without compromising efficiency.

A Good BMS Leads to Cost Savings

While power converters are fundamental for the power-conversion paths, in energy storage systems, the key component to assure the best total ownership costs is represented by the battery managing/monitoring systems (BMS). In a price-break analysis, we can see that for megawatt-range ESS, more than half of the cost is driven by the battery rack—about $200 per kWh today, expected to decrease down to $100 per kWh in 2025.

Having a reliable and precise BMS solution enables the battery to extend its lifetime by 30%, resulting in a huge cost saving and simplified operability of the complete charging station. Less maintenance means longer working time and no issues for the users, thus increasing the safety level by reducing the connected risks of repairing.

To achieve these results, the energy management system controlling the energy flows around the charging station must have a very accurate understanding of the state of charge SOC and state of health (SOH) of the energy storage battery. Precise and reliable SOC and SOH calculations permit the battery lifetime to extend 10 to 20 years in the best case, and in general a 30% lifetime improvement is achievable without increasing the electronic costs related to the BMS. This leads to a reduction of the operating and ownership costs of at least 30% given by the increased lifetime of the battery.

Combining that with higher accuracy in the SOC information makes it possible to use all of the energy stored in the batteries and charge them in the best possible way. In turn, it avoids overcharging or overdischarging, conditions that can drain the battery out in a very short timeframe and create risky situations like short circuits and fires.

For predictive maintenance, and to ensure the energy and power flows are properly managed, knowing the battery SOC and SOH means being able to predict and adjust the algorithms involved in the grid stabilization, EV charging process, and vehicle-to-grid (V2G) connection where vehicles are also seen as storage units.

Battery Monitor IC

The solution for accurate monitoring is to use a multicell—up to 18 cells—battery monitor IC with a total measurement error of less than 2.2 mV. All 18 cells can be measured in 290 µs, and lower data-acquisition rates can be selected for high noise reduction. Multiple stack monitor devices can be connected in series, permitting simultaneous cell monitoring of long, high-voltage battery strings. Each stack monitor has an isolated serial peripheral interface (isoSPI) for high-speed, RF-immune, long-distance communications.

Multiple devices are connected in a daisy chain with one host processor connection for all devices. This daisy chain can be operated bidirectionally, ensuring communication integrity, even in the event of a fault along the communication path. The IC can be powered directly from the battery stack or from an isolated supply. The IC includes passive balancing for each cell, with individual pulse-width-modulation (PWM) duty-cycle control for each cell. Other features include an on-board 5-V regulator, nine general-purpose I/O lines, and a sleep mode, where current consumption is reduced to 6 µA.

Due to the short- and long-term accuracy demands of the BMS application, the IC uses a buried-Zener conversion reference rather than a bandgap reference. This provides a stable, low-drift (20 ppm/√kh), low-temperature-coefficient (3 ppm/°C), low-hysteresis (20 ppm) primary voltage reference along with excellent long-term stability. The accuracy and stability are critical since they form the basis for all subsequent battery-cell measurements; these errors have a cumulative impact on acquired-data credibility, algorithm consistency, and system performance.

Dealing with Noise

Although a high-accuracy reference is a necessary feature to ensure superior performance, that alone isn’t enough. The ac-dc converter architecture and its operation must meet specifications in an electrically noisy environment, which is the result of the PWM transients of the system’s high-current/voltage inverter. Accurate assessment of the SOC and SOH of the batteries also requires correlated voltage, current, and temperature measurements.

To mitigate the system noise before it can affect the BMS performance, the stack monitor converter uses a sigma-delta topology, aided by six user-selectable filter options to address noisy environments. The sigma-delta approach reduces the effect of EMI and other transient noise, by its very nature of using many samples per conversion, with an averaging, filtering function. For example, the LTC6813 battery stack monitor provides 18 channels.

Conclusion

In summary, to address the challenges of the future dc fast-charging infrastructure, the critical aspects will reside in the power-conversion and energy storage systems. Designers can achieve this through a combination of isolated gate driver with power-supply controller for the power-conversion stages designed with SiC MOSFETs, as well as with a battery-monitoring device for the energy-storage batteries.

Many more areas of focus are present in these systems, from current-metering to fault-protection devices, from gas sensing to functional safety. They’re all extremely important and bring huge benefits, and companies like Analog Devices are actively working in all these subsystems to make sure we can sense, measure, connect, interpret, secure, and power all of the physical phenomena producing reliable and robust data. Such data, in turn, will be used by high-end algorithms to make sure most energy is converted from renewable sources to the loads—in this case, electric vehicles.

Stefano Gallinaro is Strategic Marketing Manager at Analog Devices Inc.