This articles is part of the Power Management Series in the Power Management section of our Series Library.

Download this article as a .PDF eBook.

The book Solar Energy Storage by Brent Sorensen notes that “electricity generated from intermittent sources requires efficient advanced electricity storage systems (ESSs). Electrical energy storage refers to the process of converting electrical energy from a power network into a form that can be stored and then converted to electrical energy when needed. Such a process enables electricity to be produced at times of either low demand or low generation cost, or from intermittent renewable energy sources, and to be used at times of high demand, high generation cost, or when no other generation means is available.”

Sorensen notes that energy storage is crucial for increasing the share of energy from renewable energy source (RES) generators. This especially applies to energy from the sun and wind, which is characterized by intermittence. However, the problem with some of the present energy storage technologies is that they can be stored for a relatively small amount of energy, and in that sense a relatively short period of time to balance intermittent energy from RES generators (i.e., hourly, daily up to a maximum weekly value).

Energy storage materially improves the stability and predictability of renewable energy. It allows higher penetration of renewables for distributed (commercial and industrial), micro-grid, and utility-scale applications where higher electricity prices, unstable grids, and lower regulatory hurdles provide a needed storage environment. Combining batteries with renewable energy can reduce diesel consumption by 75% and reduces the cost of electricity by 40% to 50% over diesel generation alone.

Flow-Battery Energy-Storage System

ViZn Energy Systems Inc. (ViZn) has bolstered its proprietary flow-battery technology to enhance the capabilities, reliability, and lifetime of all next-generation flow-battery systems for multi-megawatt energy storage applications. Designated Vanguard II, the battery stack further expands the operating range of ViZn’s systems by enhancing the fast switching and high power cycling capabilities required for many applications, further maximizing ROI and providing industry-leading payback periods.

The Vanguard II battery stack has demonstrated 20% greater capacity and is immune to cycle-life degradation, providing more headroom to handle spikes in power requirements for demanding and unpredictable applications on both sides of the meter. All ViZn flow batteries incorporate the new Vanguard II stack control technology, which eliminates life-limiting issues such as dendrite growth, simplifies cell balancing, and removes thermal and electrolyte breakdown issues associated with high frequency power switching. This unique multi-use capability is necessary for frequency regulation and other high power applications while adding value to longer duration storage. All of ViZn’s systems are scalable, adding value for even the largest utility requirements. By interconnecting multiple units, both power and energy capabilities can be increased to offer utilities, as well as commercial and industrial customers the optimal fit for any size project.

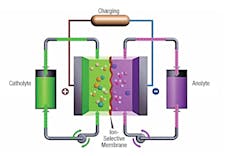

17-1. Simplified flow-battery system employed by ViZn. Pumps on the right and left bottom keep the zinc-iron electrolyte flowing.

All of ViZn’s systems utilize the inherently safe, non-toxic, non-explosive zinc-iron electrolyte as shown in the simplified system in Fig. 17-1.The ViZn battery is a redox type, which is a contraction of the terms reduction and oxidation. Redox flow batteries usually employ two electrolytes, acting as liquid energy carriers that are pumped simultaneously through the two half-cells of the reaction cell separated by a membrane. On charging, the electrical energy supplied causes a chemical reduction reaction in one electrolyte and an oxidation reaction in the other. The ion-selective membrane between the half-cells prevents the electrolytes from mixing but allows selected ions to pass through to complete the redox reaction. On discharge, the chemical energy contained in the electrolyte is released in the reverse reaction and electrical energy can be drawn from the electrodes. When in use, the electrolytes are continuously pumped in a circuit between reactor and storage tanks.

High-power flow batteries use multiple stacks of cells. The size and number of electrodes in the cell stacks is fixed and determines the system’s power rating. An advantage of this system is that it provides electrical storage capacity, limited by the capacity of the electrolyte storage reservoirs. Facilitating thermal management is use of the electrolytes as the thermal working fluids as they are pumped through the cells.

Flow batteries are typically sized for power by the physical dimensions of the electrodes. The next-generation flow batteries have greatly increased the ability to deliver power while maintaining the long duration energy capacity.

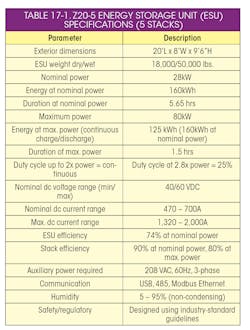

17-2. ViZn flow battery in 20’L x 8’W x 9’6”H enclosure

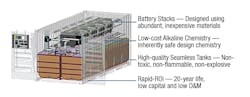

ViZn’s zinc-iron redox storage technology provides large-scale energy storage. A modular unit is a 20- or 40-foot shipping container that can be combined and scaled to provide storage solutions for projects ranging from 100 kW to 100 MW. This technology provides safety, simplicity, and the use of abundant core non-toxic raw materials to achieve a 20-year expected life. Fig. 17-2 shows a typical ViZn flow battery package and Fig. 17-3 shows the internal construction. Table 17-1 lists the characteristics of a five-stack, Z20-5 battery.

17-3. Internal construction of a ViZn flow battery.

Battery Stores Wind or Solar Power

Renewable energy power systems can take advantage of Axion’s proprietary PbC battery technology for short-term power storage. In a solar installation, the solar panels charge the batteries whose output powers a dc-to-ac inverter that provides a tightly controlled frequency and amplitude output to the utility grid. Compared with conventional lead-acid batteries, PbC batteries used with a solar or wind power system offer:

• Faster recharge rates

• Greater charge acceptance

• Longer cycle lives in deep discharge applications

• Minimal maintenance

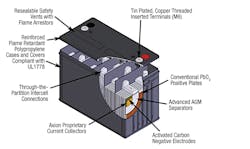

Shown in Fig. 17-4, the Axion battery is a multi-celled asymmetrically supercapacitive lead-acid-carbon hybrid battery. Like the conventional lead-acid battery, the Axion battery consists of a series of cells. Within its individual cells, however, construction is more complex. Negative electrodes in conventional lead-acid batteries have simple sponge lead plates. In contrast, the Axion’s negative electrodes are five-layer structures consisting of a carbon electrode, corrosion barrier, current collector, second corrosion barrier, and second carbon electrode. These electrode structures are sandwiched together with conventional separators and positive electrodes and its cells are connected in series. The battery is filled with an acid electrolyte and is completely sealed.

17-4. Cross-section of a PbC battery.

Since 2004, laboratory prototypes of Axion’s PbC batteries have undergone extensive testing. The test protocol involved a complete charge-discharge cycle every seven hours to a 100% depth of discharge. During testing, laboratory prototypes withstood more than 2,500 cycles before failure. In comparison, most conventional lead-acid batteries intended for deep discharge applications are only able to survive 400 to 600 cycles under similar operating conditions.

More than eight years were devoted to R&D on various aspects of this technology. Work focused on optimizing the design, including:

• Characterizing baseline performance

• Developing proprietary treatment processes for the activated carbon used in the electrodes

• Developing proprietary designs and manufacturing techniques for electrode assemblies

• Fabricating a series of material and design evaluation prototypes ranging from single-cell to multi-cell batteries.

Conventional lead-acid batteries consist of two electrodes: a positive electrode made of lead dioxide(PbO2) and a negative electrode made of sponge lead (Pb). Both the lead dioxide and sponge lead materials are pasted onto lead grids with conventional separators placed between cells that are connected in series.

The PbC battery is a hybrid device that uses the standard lead acid battery positive electrode and a supercapacitor negative electrode made of activated carbon. The specific type of activated carbon has an extremely high surface area (1500 m2/g) and has been specifically formulated for use in electrochemical applications. During charge and discharge, the positive electrode undergoes the same chemical reaction that occurs in a conventional lead acid battery, i.e., lead dioxide reacts with acid and sulphate ions to form lead sulphate and water. The main difference in the PbC battery is the replacement of the lead negative electrode with an activated carbon electrode that does not undergo a chemical reaction at all. Instead, the very high surface area activated carbon electrode stores the protons (H+) from the acid in a layer on the surface of the electrode.

With conventional lead-acid batteries, the concentration of acid changes from being very concentrated in the charged state to somewhat diluteD in the discharged state as the acid is converted to water. In contrast, the PbC battery stores H+ in the negative electrode in the fully charged state, which moves to the positive electrode during discharge where they are neutralized to form water. The result is reduced acid concentration swings from the charged to discharged state, reducing grid corrosion on the positive electrode, leading to longer positive electrode life.

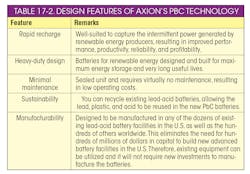

The rapid recharge and deep discharge capacity of the PbC battery are well-suited for intermittent power sources like wind and solar. When coupled with the ability to deliver longer cycle lives with minimal maintenance, grid connected systems based on our PbC technology will offer a greater total number of useful cycle lives. If battery cost per charge/discharge cycle is low enough, peak shaving and grid buffering for traditional utilities may also be cost effective. Table 17-2 lists the PbC battery’s design features.

Axion has also developed the PowerCube, a mobile energy storage system using multiple PbC batteries that can be configured to deliver up to 1 MW for 30 minutes or 100 kW for 10 hours (Fig. 17- 5).

17-5. PowerCube with PbC batteries providing 1MW for 30 minutes.

Solar Installation

For more than two and a half years, Axion’s 500kW PowerCubes have been connected into the PJM grid utility network, one of the nation’s largest power transmission organization serving more than 58 million people in all or parts of 13 states. Set up as a demand response and frequency regulation asset, Axion developed and tweaked a working model in a real-world setting utilizing the PowerCube’s ability to participate 24/7 in the PJM frequency regulation application.

Following the initial installation, Axion received a follow-on order for four more PowerCube energy storage systems. The Cubes will provide storage for energy created by a commercial solar panel system and provide power storage and frequency regulation on the PJM grid. In addition, ancillary circuits provide seamless switching between the output of the solar-inverter and the utility’s generators. The new order includes batteries, racks, wiring, a data communication system, and the electronics coordination needed to outfit and install the PowerCubes. Each of the PowerCubes will be tied to solar arrays that produce between 500kW and 700kW and the PowerCubes will each provide 500kW (both 500kW up and 500kW down) for frequency regulation.

Li-ion Batteries Compete

According to Marianne Boust, principal analyst, IHS Technology, massive cost reductions have permitted Li-ion technology to surpass lead-acid batteries in energy storage. Li-ion is even challenging sodium sulfur and flow for long-duration storage. Li-ion is also gaining traction in the grid-scale market for longer duration, which has been historically dominated by sodium sulfur and flow batteries. However, flow-battery manufacturers are scaling up their ambitions and betting on superior lifetime of flow-battery technology. While equipment costs keep falling, policies favorable to energy storage are being implemented in a larger number of countries, driving up new demand in the power sector.

Read more articles from the Power Management Series in the Power Management section of our Series Library.

About the Author

Sam Davis

Sam Davis was the editor-in-chief of Power Electronics Technology magazine and website that is now part of Electronic Design. He has 18 years experience in electronic engineering design and management, six years in public relations and 25 years as a trade press editor. He holds a BSEE from Case-Western Reserve University, and did graduate work at the same school and UCLA. Sam was the editor for PCIM, the predecessor to Power Electronics Technology, from 1984 to 2004. His engineering experience includes circuit and system design for Litton Systems, Bunker-Ramo, Rocketdyne, and Clevite Corporation.. Design tasks included analog circuits, display systems, power supplies, underwater ordnance systems, and test systems. He also served as a program manager for a Litton Systems Navy program.

Sam is the author of Computer Data Displays, a book published by Prentice-Hall in the U.S. and Japan in 1969. He is also a recipient of the Jesse Neal Award for trade press editorial excellence, and has one patent for naval ship construction that simplifies electronic system integration.

You can also check out his Power Electronics blog.