Download this article in PDF format.

The advanced driver-assistance system (ADAS) market is expected to reach $60B globally by 2020, according to Allied Market Research, representing a CAGR of 22.8% from the years 2014 to 2020. Clearly, this represents a significant opportunity for semiconductor content.

Commonly found in many of today’s new automobiles, an ADAS usually facilitates safe driving and can alert the driver if the system detects risks from surrounding objects such as errant pedestrians, cyclists, or even other vehicles on an unsafe trajectory. Furthermore, these systems typically provide dynamic features such as adaptive cruise control, blind-spot detection, lane-departure warning, driver-drowsiness monitoring, automatic braking, traction control, and night vision.

Consumer demands for more safety and comfort while driving, along with the continued increase of government safety regulations have been the main growth drivers of ADAS in automobiles for the latter half of this decade. However, such growth also exacerbates and/or creates new challenges for the industry, ranging from pricing pressure and inflation to design complexity and difficulty in testing these systems.

On top of that, it should come as no surprise that the European automotive industry—which represents one of the most innovative automotive market—has seen major market penetration and adoption of ADAS from its customers. But both American and Japanese automakers are not far behind that curve. What many manufacturers see as the ultimate goal, though, is an autonomous driving machine without the need for a human being behind the wheel.

System Challenges

Generally speaking, an ADAS system incorporates some kind of microprocessor to gather all of the input from the numerous sensors within the vehicle, and then process that data so that can be presented to the driver in an easy-to-understand manner. These systems are usually powered directly from the vehicle’s main battery, which is a nominal 9 to 18 V. However, it could run as high as 42 V due to voltage transients within the system, and as low as 3.5 V during a cold-crank condition. As a result, any dc-dc converters within these systems must be able to handle the wide input voltage range of 3.5 to 42 V, at a minimum.

Many ADAS systems employ a 5- and 3.3-V rail to power their various analog and digital IC content; however, the typically used processor I/O and core voltages will have operating requirements in the sub-2-V realm, and could be as low as 0.8 V. Furthermore, the system is usually mounted in a part of the vehicle that’s both space and thermally constrained, thereby limiting the heat sinking available for cooling purposes.

While it’s commonplace to use a high-voltage dc-dc converter to generate a 5- and 3.3-V rail directly from the battery, the switching regulator in today’s ADAS systems must switch at 2 MHz or greater, rather than at the traditional sub-500-kHz frequency. The key driving force behind this change is the need for smaller solution footprints while also staying above the AM frequency band to avoid any potential interference.

Need to Knock Down the Noise

Finally, as if the designers task isn’t already complicated enough, they must also ensure that the ADAS system complies with the various noise-immunity standards within the vehicle. In an automotive environment, switching regulators are replacing linear regulators in areas that require low heat dissipation and efficiency. Moreover, the switching regulator is typically the first active component on the input power bus line, and therefore will significantly impact the electromagnetic-interference (EMI) performance of the complete converter circuit.

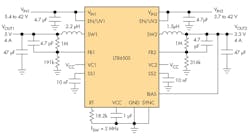

At 2 MHz, Linear Technology’s LT8650S power converter delivers power outputs of 5 V at 4 A and 3.3 V at 4 A.

There are two types of EMI emissions: conducted and radiated. Conducted emissions ride on the wires and traces that connect up to a product. Since the noise is localized to a specific terminal or connector in the design, a good layout or filter design often can assure compliance with conducted emissions requirements relatively early in the development process.

However, radiated emissions are another story altogether. Everything on the board that carries current radiates an electromagnetic field. Every trace on the board is an antenna and every copper plane is a resonator. Anything beyond a pure sine wave or dc voltage generates noise all over the signal spectrum. Even with careful design, a power-supply designer never really knows how the bad the radiated emissions are going to be until the system is tested. And radiated emissions testing can’t be formally performed until the design is essentially complete.

Designers often rely on filters to reduce EMI, because they have the ability to attenuate the strength at a certain frequency or over a range of frequencies. The portion of this energy that travels through space (radiated) is attenuated by adding metallic and magnetic shields. The part that rides on PCB traces (conducted) is tamed by adding ferrite beads and other filters. EMI can’t be completely eliminated, but it can be attenuated to a level that’s acceptable by other communication and digital components. Moreover, several regulatory bodies enforce standards to ensure compliance.

Modern input-filter components in surface-mount technology perform better than through-hole parts. However, this improvement is outpaced by the increase in operating switching frequencies of switching regulators. Higher-efficiency, low-minimum on and off times result in higher harmonic content due to the faster switch transitions. For every doubling in switching frequency, the EMI becomes 6 dB worse; meanwhile, all other parameters, such as switch capacity and transition times, remain constant. The wideband EMI behaves like a first-order high-pass filter with 20-dB-higher emissions if the switching frequency increases tenfold.

Finding the Right Solution

Savvy PCB designers will make the hot loops small and use shielding ground layers as close to the active layer as possible. Nevertheless, device pinouts, package construction, thermal design requirements, and package sizes that provide adequate energy storage in decoupling components dictate a minimum hot-loop size. To further complicate matters, in typical planar printed circuit boards, the magnetic- or transformer-style coupling between traces above 30 MHz will diminish all filter efforts. That’s because as harmonic frequencies rise, unwanted magnetic coupling becomes all that more effective.

Finding a power-conversion device that meets all of the necessary performance metrics so as not to interfere with the ADAS system is a difficult task. However, there is a power converter that can help system designers overcome the challenges discussed in this article, including EM/EMI emission reduction: Linear Technology’s LTC8650S (see figure). It can also deliver all of the required performance without requiring sophisticated layout or design techniques.

ADAS will no doubt continue to proliferate in automotive designs as time wears on, so it’s incumbent on engineers to find ways to maximize the capabilities of these systems to meet demands. And one step in creating such solutions is pinpointing the right components to do the job.