What you'll learn:

- What is the definition of a "structural" battery?

- Materials used by the research team to create this innovative structural battery.

- Initial performance results of the battery.

Having a physical element of a design do “double duty” as both a structural-support element and perform a functional role isn’t a new idea for saving weight and reducing size. In fact, it’s a standard engineering strategy. In many cases, of course, this is easier said than done. Such is the case with larger rechargeable batteries, where the support structure and the internal elements are largely disparate entities.

Now, a team at Chalmers University of Technology (Sweden) has produced what they call a “structural battery” that performs 10X better their previous efforts in this area. Using lithium-based chemistry, it contains carbon fiber that serves simultaneously as an electrode, a conductor, and load-bearing material (Fig. 1).

There is a tradeoff: This battery has an energy density of about 24 Wh/kg, which they acknowledge is approximately 20% of the capacity of comparable lithium-ion batteries currently available. The researchers maintain that this isn’t as big a drawback as it may seem at first—since the weight of the vehicles can be greatly reduced, less energy will be required to drive an electric car. For example, the battery of the Tesla model S (85 kWh) is ≈25% of the total vehicle weight.

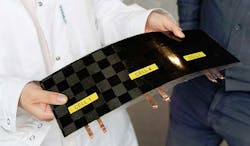

The new design has an elastic modulus (stiffness) of 25 GPa and tensile strength exceeding 300 MPa. The structural battery is made from multifunctional constituents, with reinforcing carbon fibers (CFs) acting as electrode and current collector. A structural electrolyte is used for load transfer and ion transport, and a glass-fiber fabric separates the CF electrode from an aluminum-foil‐supported lithium-iron-phosphate positive electrode. As is typical of battery construction, the fabrication of the structural battery is a complex, multistep process (Fig. 2).

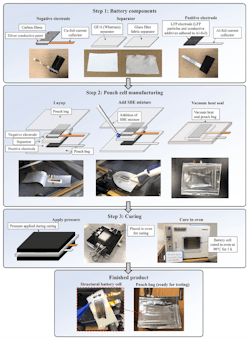

Two types of glass-fiber (GF) fabric separators—designated as Whatman GF/A and a GF plain weave—were used as model materials to investigate the effects of separator thickness and architecture, as well as material anisotropy, on the multifunctional performance. The researchers provided detailed charts and tables of electrical and mechanical performance for the two weaves of the fabric (Figs. 3 and 4, respectively).

This isn’t their first effort in this area. The previous attempt to make a structural battery was in 2007, but it was difficult to manufacture batteries with both good electrical and mechanical properties. With this latest development (a collaboration with KTH Royal Institute of Technology, Stockholm), they have achieved a structural battery with greatly improved properties with respect to electrical energy storage, and stiffness and strength. They also maintain that the multifunctional performance is 10X higher than previous structural battery prototypes.

As explained by Leif Asp, Professor at Chalmers and leader of the project, “Previous attempts to make structural batteries have resulted in cells with either good mechanical properties, or good electrical properties. But here, using carbon fiber, we have succeeded in designing a structural battery with both competitive energy storage capacity and rigidity.” (Note: the project team is using the term “massless energy storage” for their work because they maintain that, in essence, the battery’s weight “vanishes” when it becomes part of the load-bearing structure. However, this seems to me to be quite a stretch of terminology and fundamental physics.)

A follow-on project is underway, financed by the Swedish National Space Agency, with the goal of further increasing the performance of the structural battery. The aluminum foil will be replaced with carbon fiber as a load-bearing material in the positive electrode, providing both increased stiffness and energy density. The fiberglass separator will be replaced with an ultra-thin variant, which will deliver a much greater effect—as well as faster charging cycles.

The new project is expected to be completed within two years. Prof. Asp estimates that such a battery could reach an energy density of 75 Wh/kg and a stiffness of 75 GPa, thus making the battery about as strong as aluminum, but with a much lower weight.

Details of the project are available through multiple resources:

- Their paper in Advanced Energy and Sustainability Research (HTML): “A Structural Battery and its Multifunctional Performance”

- The same paper (pdf): “A Structural Battery and its Multifunctional Performance”

- “Supporting Information” (Word document)

- Video: “Battery Being Connected” (1:10)

- Video: “Fabrication Process” (1:24)

- Video: “Massless Energy Storage” (2:22)