Basics of DC Motor Power Density

This article is part of the Power Management Series: Delving Into Power Density

Members can download this article in PDF format.

What you'll learn:

- Specifics about high-power-density motors (HPDMs).

- Applications best served with HPDMs.

- Why BLDCs are perhaps the most preferred among HPDM architectures.

High power density is an important characteristic in most motors, even in a tiny motor with a high-power-output capability. A high-power-density motor (HPDM) is one that has a high ratio of power/volume.

The smallest motors can even have a high power output. HPDMs are low-speed, high-torque motors. These motors are usually lightweight, small, and have large amounts of torque and lower cogging torque. Cogging torque is defined as the torque necessary to overcome an opposing torque that’s created by the magnetic attractive force between the rotor magnets and the stator iron teeth.

In HPDMs, a great many motor manufacturers will alloy cobalt with iron (CoFe); however, this is a high-priced alloy. The mineral cobalt is used because it can attain the highest maximum saturation magnetization over all other materials. These motor designs will achieve a high maximum flux density, which can significantly decrease the size and weight of electrical motor cores.

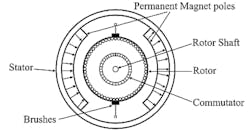

The permanent-magnet dc (PMDC) motor, an HPDM, has poles made from permanent magnets. These magnets are magnetized radially and mounted on the inner area of the cylindrical steel stator. The motor stator acts as a return path for the magnetic flux. The rotor is constructed with a dc armature along with commutator brushes and segments (see figure).

Applications for High-Power-Density Motors

Drones

One prime application for an HPDM is a drone. Brushless dc (BLDC) permanent-magnet motors, for example, can offer high power density for drone designs. These types of motors, with a high power-to-mass/volume ratio, can easily power drone propellers/rotors.

There are even industrial, heavy-lift, dc drone motors for 50 kg or more thrust capability. These motors usually use lightweight carbon-fiber propellers.

Automotive

Another important type of lightweight, battery-powered application is an automotive high-power-density system. Such designs are able to shrink automotive power system size, weight, and component count. Designers can create efficient power modules that are able to drive HPDMs, enabling lightweight and efficient power designs for all types of electric vehicles (EVs).

Medical

HPDMs in the medical field enable smaller medical end devices and applications. These kinds of motors provide operation in important applications for portable or wearable devices, such as miniature pumps and medical implantables. A few examples of dc motors requiring high power density include:

- Surgical hand tools, which need high-performance small motors that operate with lower vibration and noise with EMI/RFI reduction.

- Hospital infusion pumps, which demand high-efficiency and high-torque-density motor solutions. These will enable reduced size and increased battery backup life, especially for mobile clinical pumps. These motors will reduce pump size because HDPMs have shrunk to single-digit millimeter diameters.

- Aerospace applications, which use small, lightweight, but powerful motors that also can be used in applications requiring precision and the ability to withstand harsh environments.

Industrial

A major application area involves industrial power tools designed with BLDC motors. High-power-density BLDC motors are being used in positioning, servo, actuation, and variable speed. In such applications, motor operating stability and precision motion control will be primary goals in the industrial and manufacturing sectors.

Powered screwdrivers, hand drills, nail guns, and pruning shears are just a few of the specific applications. HPDMs in these kinds of devices will reduce package size and weight in the overall design as well.

Summary

In many applications, space and weight must be kept to a minimum. Power density is a critical factor in meeting such design constraints.

If designers are seeking the best power density in their designs, with one of the key components being a motor, the best choice would most likely be a brushless dc motor architecture. Standard BLDC motors have a decided advantage over a brushed dc or ac motor due to their excellent power density.

Some manufacturers of BLDC motors have incorporated new BLDC motor control technologies that can increase power density. Size, weight, power, and cost savings are achievable by combining the control and power amplification sections of the motor controller into one single solution.

Read more articles in the Power Management Series: Delving Into Power Density

Reference

1. “Permanent Magnet DC (PMDC) Motor – Construction, Working, and Speed Control,” tutorialspoint.com.