High Voltage and GaN: Gateways to Better Power-Supply Efficiency

Download this article in .PDF format

Every electronic device has a power supply. Most of those power supplies are of the switch-mode variety, which offer good efficiency. These include ac-dc supplies, dc-dc converters, ac motor drives, and inverters for solar-power conversion. Yet, as recent developments show, efficiency can be further improved by using GaN semiconductor devices and high-voltage techniques. These and other benefits can be realized thanks to the arrival of new products.

The Problem

Switching power supplies have brought greater power efficiency to electronic products. In an era of ever-increasing electronic product usage, efficiency has become a primary design objective, be it for portable battery-powered items or mains-powered commercial and consumer equipment. It’s also a top priority in industrial equipment designs.

There’s no better example of the need for greater efficiency than data centers. With thousands of servers routing internet connections, a data center burns more electricity than almost any other commercial facility. And that doesn’t include the massive cost of air conditioning to keep all of those servers cool. Even small improvements in efficiency can greatly reduce electrical and cooling costs.

The losses that most contribute to inefficiency include the on-resistance and turn-on/turn-off time of switching devices. Most switching supplies use standard silicon MOSFETs. The devices consume no power when off, of course. When switched on into a saturated state, they do burn some power because of their conduction resistance, low as it may be.

Another factor is switching time. As the MOSFET switches from on to off and vice versa, the device passes through its linear region, where it consumes power. The slower the rise and fall times, the more power burned.

The obvious solution is to find a faster device with lower on-resistance, if it exists. And oh by the way, make sure the device can handle the high voltages usually encountered in commercial- and industrial-grade equipment.

Finally, the design architecture of the power supply should be reconsidered. Especially important is the number of energy-conversion stages used in the design. Each stage introduces its own inefficiency, compounding the problem.

The Solution

As a first step in design, minimize the number of energy-conversion stages. Each stage of rectification, regulation, dc-dc conversion, or other energy-transfer process adds a level of inefficiency. One approach to this is to start with higher voltages and use fewer stages. Higher voltage usually means less current. Higher-current, low-voltage circuits always consume more power.

Keep in mind the basic premise behind the electric utility’s reason for long-distance transmission of electrical power at kilovolt levels. Higher voltages result in lower current for a given power, which produces less voltage drop per mile of transmission line.

The goal is to start with higher input voltages, ac or dc, and bring them into the supply and convert to lower voltages as quickly as possible. Use the 480- or 240-V ac lines or the solar-array dc output of hundreds of volts directly. Electric car chargers use 240 V ac and the car batteries are usually several hundred volts. The secret to a high-voltage design is to find the HV components like diodes and transistors that can handle this voltage.

High-voltage diodes have been available for years and standard silicon MOSFETs continue to improve. They can handle voltages up to about 1000 V with reasonably fast switching and low on-resistance. However, one newer device with the greatest potential in power supplies is the GaN MOSFET. These gallium and nitrogen compound devices naturally switch faster and have lower on-resistance than their silicon counterparts. Moreover, they can handle the HV.

GaN devices have met with big success as microwave and millimeter-wave RF power amplifiers. These high-voltage devices provide hundreds and even thousands of watts of power at ever-increasing radio frequencies. Now GaN devices are being optimized for power-conversion applications.

One benefit of adopting GaN devices is that the power supply can be switched at higher frequencies beyond the usual several hundred kilohertz. Using switching rates above 1 MHz allows ripple to be reduced using smaller capacitors and inductors. Filtering becomes easier, and the smaller components make it possible to shrink overall size.

One key issue with GaN devices is that they are depletion-mode MOSFETs—they normally conduct and thus have to be driven off with a gate input. Standard silicon MOSFETs are enhancement-mode devices that are normally off and must be gate-driven to turn them on. Such devices are easier to use and drive circuits are simpler.

GaN MOSFETs, on the other hand, require special, more-complex drive circuits. This is an issue worth dealing with as switching times are faster in the nanosecond region. In addition, on-resistance drops down into the tens of milliohms range.

An Example Solution

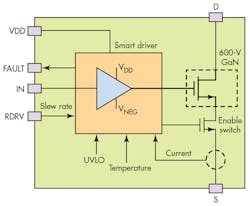

Newer silicon MOSFETs do provide some improvements in efficiency. However, even better alternative solutions for switch-mode power designs are now available. One of these is a silicon-carbide (SiC) MOSFET that provides not only lower on-resistance and faster switching, but also very high voltage tolerance. An even better choice, though, is a GaN device with improved specifications. An example is Texas Instruments LMG3410 GaN power device (see figure).

It’s a single GaN MOSFET with internal driver circuits that simplifies design and application. It can handle up to 600 V and 12 A. The device is usable in designs with up to 1-MHz steady-state operation. Propagation delay is 20 ns, and switching time is adjustable over the range of 25 to 100 V/ns, making it possible to control EMI while optimizing efficiency. On-resistance is a low 70 mΩ.

Looking at the figure, a key feature of the LMG3410 is its internal gate driver that keeps the GaN transistor off in its normal state. An internal dc-dc converter generates the negative voltage needed to keep the device biased off. An input signal in the 3- to 5-V range turns the GaN device on. When the device is unpowered, a series silicon MOSFET keeps the GaN device disconnected or off.

The LMG3410 also has multiple safety and protection features that include undervoltage lockout (UVLO) as well as overcurrent and overtemperature protection. A fault output signal indicates the device’s status. All of this is housed in an 8- × 8-mm QFN package.

When designing a new switch-mode supply, take a look at some of the newer devices like those mentioned. Even single-digit improvements in efficiency can go a long way toward reducing power consumption and heat. Furthermore, operating at higher frequencies enables the use of smaller capacitors, inductors, and other components, resulting in more compact packages that are easier to cool. Cost reductions are possible.

About the Author

Lou Frenzel

Technical Contributing Editor

Lou Frenzel is a Contributing Technology Editor for Electronic Design Magazine where he writes articles and the blog Communique and other online material on the wireless, networking, and communications sectors. Lou interviews executives and engineers, attends conferences, and researches multiple areas. Lou has been writing in some capacity for ED since 2000.

Lou has 25+ years experience in the electronics industry as an engineer and manager. He has held VP level positions with Heathkit, McGraw Hill, and has 9 years of college teaching experience. Lou holds a bachelor’s degree from the University of Houston and a master’s degree from the University of Maryland. He is author of 28 books on computer and electronic subjects and lives in Bulverde, TX with his wife Joan. His website is www.loufrenzel.com.