Read the full article, "New Position Sensors Follow Many Paths to Precision."

Gauging displacements and the angular positions of motor shafts has always been an interesting challenge on the cusp between mechanical and electronic engineering. Here are a few of the more approaches that have been popular in the past:

Linear-position and displacement sensors are the most likely choice for industrial and commercial applications of 100 min. to 100 in. (2.5 mm to 2.5 m). Generally, electromechanical linear position and displacement sensors are one of six basic technologies: resistive, capacitive, inductive, magnetic, time-of-flight, and pulse encoding.

Resistive sensors or potentiometer slide a contact against a fixed resistive element to generate changes in resistance. Hooked to a dc source as a voltage divider, they produce a proportional voltage output when used with high-impedance loads. They are relatively economical; servos on radio-controlled model airplanes frequently employ potentiometers for position feedback. However, their use of a sliding contact gives them poor repeatability, large hysteresis, and an output that tends to deteriorate over time from wear, particularly in the presence of vibrations.

Magnetoresistive sensors are sometimes considered contact-free variations on the potentiometer. They are comprised of a special metallic film whose electrical resistance varies in a magnetic field. This sensing material is often configured in a Wheatstone bridge to cancel out temperature coefficients (around 0.3%/K) and resistor tolerances. The bridge may be balanced by laser-trimming the magnetoresistive material.

Magnetoresistive sensing is sometimes confused with magnetostrictive sensing. Magnetostriction is a property of ferromagnetic materials such as iron that expand or contract when placed in magnetic field. Magnetostrictive sensors are used to measure linear position. They measure the position of a permanent magnet (position magnet) to determine the distance between the permanent magnet and the sensor head. The magnet doesn’t touch the shaft and thus has no wear.

Magnetostrictive sensors use the principle of time-of-flight for gauging distances. The electronics send out some type of wave (usually sound or light) down the waveguide of magnetostrictive material toward the moving target (magnet) and measure the time necessary to receive a reflection. The moving magnet creates a torsional pulse in the magnetoresistive waveguide. The pulse moves down the waveguide at a known speed to a wave detector. Thus the output is proportional to the magnet position relative to the detector.

Magnetostrictive sensors offer high resolution, high repeatability, and exhibit good temperature stability over a limited temperature range. They are particularly useful for relatively long ranges, typically from 6 to 120 in. (150 mm to 3 m) or more.

There are other sensors that use the time-of-flight principle to gauge distances. Ultrasonic and laser time-of-flight sensors-depend, of course, on timing the reflection of sound and light, respectively. Both are contactless but the dimensions of the target and its orientation can affect the measurement. For ultrasonics, air temperature, humidity, and wind also can introduce errors into readings. Nevertheless, ultrasonic sensors are generally economical and reliable enough for range finding and liquid-level sensing where precision is not a key. Depending on the operating frequency, ultrasonic sensors measure distances ranging from a few inches up to 33 ft. (0.1 to 10 m).

Laser sensors also work from reflection time and offer high precision and excellent repeatability. But they are relatively expensive and generally require targets with the right reflectivity for best results. Lasers also may pose a hazard to human eyesight. Typical ranges are from fractions of an inch to hundreds of inches (a few millimeters to dozens of meters).

For smaller distances, capacitive or inductive sensors may fit the bill. Capacitive sensors rely on the changing capacitance between two plates—one fixed, the other free to move—to signal changes in linear position of up to about 0.4 in. (10 mm). Their support electronics is more complicated than resistive devices and they are susceptible to humidity changes and temperature extremes. Their primary use is in short-range dimensional gaging of mechanical parts, and in these applications, they have high resolution and good accuracy.

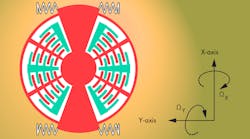

Inductive sensors measure inductance variations caused by movement of a flux-concentrating element (usually a wire coil). They are contact-free and often used where long-term reliability is important, particularly in harsh and hostile environments. There are three basic types of inductive sensors: LVDTs (linear-variable differential transformers), LVRTs (linear-variable reluctance transducers), and LVITs (linear-variable inductance transducers). All of them need ac signal conditioning or support electronics.

LVDTs usually measure movements between 0.01 and 10 in. (0.25 to 250 mm). They generate a signal proportional to the linear displacement from a mechanical reference (zero, or null position). The signal contains phase (for direction) and amplitude (for distance) information. An LVDT typically has three solenoid coils placed end-to-end around a tube. The center coil is the primary and the two outer coils are secondaries. A cylindrical ferromagnetic core, attached to the object of interest, slides along the axis of the tube. An ac signal to the primary induces a voltage in each secondary proportional to the length of the core linking to the secondary. The frequency is usually in the low kilohertz range.

The amount of linkage between the primary and the two secondary coils changes as the core moves. The coils connect so the output voltage is the difference between the two secondary voltages. When the core is equidistant between the two secondaries, the two secondary coil voltages cancel so the output voltage is theoretically zero.

As the core moves, the voltage in the corresponding secondary coil rises while the voltage in the other drops, pushing the output voltage away from zero. This output voltage is in phase with the primary voltage. When the core moves in the other direction, output voltage also rises from zero, but in the opposite polarity. The phase of the output voltage gives the direction of the displacement, and amplitude indicates the amount of displacement.

LVDTs can serve as absolute position sensors because they show the same output on restart after power is switched off. LVITs generally use just one coil. A conductive target, typically a rod or slide, is set up to pass over or through the coil. As with LVDTs, eddy currents are induced in the target, which changes the inductance of the coil. Typical targets are conductive but nonmagnetic materials such as aluminum and stainless steels. However, they generally operate in the 2-MHz frequency range, making them sources of and susceptible to electromagnetic interference. They can be found in ranges up to 40 in. (1 m).

LVRTs also use one coil and are usually configured as half bridges with a central connection to the middle of the coil. They are widely used in Europe where they serve as spool position feedback sensors in servovalves and in short-range dimensional gaging probes. They are thought of as less expensive than LVDTs but have lower outputs for a given size. LVRTs typically have ranges under 0.4 in. (10 mm).

Finally, pulse-encoding sensors usually measure incremental movements and don’t note absolute position without some kind of homing operation, although there are some absolute encoders. The typical orientation of these devices is to optically read linear graduations on a glass scale or detect magnetic poles uniformly spaced on ferromagnetic material. Ancillary electronics counts the graduations or poles to discern the amount of movement over a given time period. These devices perform with high precision generating quasi-digital output and are used primarily in robots, machine tools, and similar applications. Encoders have a limited frequency response, however, so they are best suited for slower dynamic applications. Measurement distances range from 6 to 60 in. (0.15 to 1.5 m).