3D Printing Meets THz Waves: An Odd Couple Delivers Focused Results

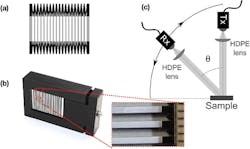

3D printing and terahertz-wave manipulation aren’t terms you would expect to see in the same sentence, but they can be made to work together. Researchers at Philipps-Universität Marburg (Germany) and Centro de Investigaciones en Óptica, A.C. (León, Mexico) joined forces to create a 3D-printed diffraction grating that can be used to reflect and steer terahertz (THz) waves. They “printed” a reflective diffraction grating starting with a one-dimensional array of 17 plastic strips, each 50 mm long and 0.8 mm wide, covered it with aluminum foil, and then connected them by V-shaped springs (Fig. 1).

1. The 3D-printed grating is an accordion-like panel with a thin aluminum layer for reflecting the impinging electromagnetic radiation. (Source: Philipps-Universität Marburg)

The adjustable grating was then mounted in a vise, also 3D-printed, and used to apply pressure to adjust the dimensional spacing of the strips (Fig. 2). The array period was 2.3 mm when relaxed but could be continuously reduced to 1.1 mm by applying lateral pressure via the vise action.

2. The grating is mounted in a 3D-printed vise that can precisely compress the folds to adjust the spacing and periodicity of the rows, and thus the grating’s spectral characteristics. (Source: Laser Focus World)

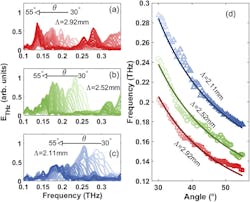

Tests over the range of 0.1 to 1 THz showed the device’s usefulness for steering a terahertz beam though angles of 25 degrees or greater. To measure the grating’s performance, they created a dataset using terahertz waveforms with detector-arm angles between 30 and 55 degrees in 0.5-degree steps (Fig. 3).

3. (a) Photograph of the free-standing grating as printed. (b) Photograph of the grating in its pressing mount; a close-up image of three periods of the grating with a reference scale on the right-hand-size (1 mm per line) is provided. (c) Schematic of geometry of the THz optical path; the receiver and its corresponding lens are mounted on a motorized goniometer in order to vary the detection angle. (Source: Philipps-Universität Marburg/Centro de Investigaciones en Óptica, A.C.)

The compression on the grating was increased (decreasing the periodic spacing of the grating) with the measurements repeated using three different compressions (Fig. 4). The results were obtained by Fourier transformation of the waveforms.

4. (a) The spectra obtained for angles between 30 degrees (lighter color) and 55 degrees (darker color) in 0.5-degree steps for the grating compression with a period of 2.92 mm. The spectral peak clearly shifts as a function of the detection angle as indicated by the arrow; on the right-hand side, additional peaks can be seen, which correspond to the second diffraction order. (b) and (c) show analogous sets of spectra for compressions with period of 2.52 mm and 2.11 mm, respectively; notice that the collection of spectral peaks for the first-order diffraction appear at higher frequencies as the period decreases. (d) The peak frequency of all the spectra shown in panels (a) = □, (b) = ◯, and (c) = △ are plotted here. The continuous lines represent the relation between the frequency and the angle of the first-order diffraction. (Source: Philipps-Universität Marburg/Centro de Investigaciones en Óptica, A.C.)

The research project didn’t stop with this basic arrangement and test, as the team decided to test the possibility of “active” beamsteering using a different arrangement. They 3D-printed a larger grating optimized for 120-GHz operation and placed it in a mount, and then fixed and coupled the ensemble to an audio speaker. By doing so, the oscillations from the speaker were able to impose a compression/decompression motion on the grating.

The speaker was driven by a 60.5-Hz sine wave (chosen due to mechanical resonance issues, not the ac-line frequency); they were able to see the impinging continuous-wave (CW) THz beam being steered forward and backward, and synchronized to the speaker motion. Full details on both parts of the project are in their paper “Terahertz beam steering using active diffraction grating fabricated by 3D printing” published in the OSA’s Optics Express.