What you’ll learn:

- The benefits and disadvantages of pellistor sensors.

- The benefits and disadvantages of NDIR sensors.

- How MPS sensors overcome the issues with pellistor and NDIR sensors.

- Results of testing among the three sensor types.

Pellistor/catalytic (CAT) bead sensors and non-dispersive infrared (NDIR) sensors have been the primary gas-detection methods for many decades. After NDIR was introduced in the 1960s, the gas-detection industry experienced a prolonged era with little innovation, until recently.

NDIR for Detecting Gas Leaks

Non-dispersive infrared sensors, or NDIR, were introduced in the 1960s and have been widely used for gas-leak detection since that time (Fig. 1). This technology works by using infrared light to detect different wavelengths absorbed by gases. These sensors consist of an infrared source, a detector, an optical filter, a gas cell, and signal-processing mechanisms. Infrared light is absorbed as a particular gas passes through an active filter, while infrared light that doesn’t interact with the target gas goes through a reference filter. The sensor determines the difference between these two transmitted light intensities to develop a gas concentration.

And while NDIR was the height of gas-detection technology 40 years ago—and for several decades after—this technology does have some notable limitations:

- NDIR is unable to detect hydrogen as this gas doesn’t absorb infrared light. Hydrogen is an incredibly dangerous gas in the mining and petroleum industries, and NDIR's inability to detect it can mean that a potentially hazardous work environment goes undetected.

- NDIR sensors are very sensitive to temperature and humidity changes, and moving through even moderate temperature transitions can freeze their output.

- NDIR sensors can be tuned to accurately detect only a single gas, making them ineffective in mixed-gas environments.

- Humidity, fog, and ambient infrared light may seep into the open chamber and cause interference.

- NDIR uses proprietary technology, making it an expensive option.

Despite their widespread use in detecting gas leaks for the last several decades, the limitations of NDIR sensors have left the market desiring more reliability, which new technologies have addressed. NDIR’s inability to detect hydrogen can lead to unsafe working environments and the sensitivity of the sensors make them ineffective in many environments.

Using Pellistor/Catalytic Bead Sensors to Detect Gas Leaks

Pellistor/catalytic bead sensors pre-date NDIR technology (Fig. 2): They have been used for gas-leak detection for nearly a century. Among the advantages of Pellistor/catalytic bead gas sensors are that they’re relatively inexpensive and sensitive to nearly all flammable gases. And they can detect hydrogen, methane, butane, propane, and carbon monoxide, as well as other gases.

These sensors contain two small beads, one of which is inert while the other is coated in a chemical catalyst. A heater within the sensor raises the temperature and measures the difference in temperature between the two beads. The presence of flammable gas causes the catalytic bead to heat more than the inert bead. The sensor provides a reading that corresponds to the concentration of the hazardous gases present in the vicinity.

Unfortunately, similar to NDIR, pellistor/catalytic bead sensors have some severe limitations:

- They’re prone to poisoning. Once these sensors come into contact with high concentrations of flammable and combustible gases, the catalyst is burned up, and the sensor is deactivated. Poisoning can occur even when the sensor encounters common chemicals such as silicones, chlorine, lead, phosphates, and acidic gases.

- Even when the sensor has been poisoned, it will appear to be working normally. This tendency may create an incredibly hazardous working environment if a user believes that the sensor is operational when, actually, it’s failing to alert the user to the presence of dangerous gases.

- If it’s calibrated to a single gas, the sensor will output inaccurate readings for all other gases.

- These sensors don't work in low-oxygen environments, including confined spaces.

- They require high amounts of power.

While the pellistor/catalytic bead sensors offer users some advantages, their limitations can increase the risk that a hazardous gas leak has gone undetected.

Molecular Property Spectrometer in Detecting Gas Leaks

The Molecular Property Spectrometer (MPS) combines the benefits of both the NDIR and pellistor gas sensors while also overcoming their major limitations (Fig. 3). This sensor uses a microelectromechanical-system (MEMS) transducer to measure changes in the thermal properties of the surrounding air and gases in the near vicinity. The output reading contains multiple indicators and environmental data to identify the types and concentrations of flammable, combustible, or hazardous gases nearby.

The benefits of using MPS sensors to detect gas leaks include:

- Delivering an accurate reading of gas mixtures, including type and concentration. MPS sensors detect the full range of flammable gases quickly.

- They provide automated environmental compensation

- MPS sensors have a life expectancy of up to five years, and one calibration can deliver an accurate measurement of 12 gases for up to a year providing true lower-explosive-limit (LEL) readings.

- They’re impervious to poisoning.

- They have fail-safe and built-in diagnostic capabilities that will alert the user if the sensor becomes inoperable.

- They use less power than NDIR and pellistor sensors.

- They’re an affordable gas-leak-detecting option.

MPS sensors represent a leap forward in gas-leak-detection technology. They overcome the challenges with detecting mixed gases and delivering accurate results for a prolonged lifespan that otherwise plague NDIR and pellistor/catalytic bead sensors.

Performance Testing Gas-Leak-Detection Sensors

During testing, MPS performed better than both the NDIR and pellistor gas sensors. Check out the video:

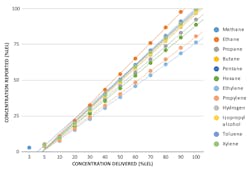

The results below were obtained in tests where all three sensors were calibrated to methane, then exposed to 50% LEL of methane, hydrogen, and butane (Fig. 4).

Methane

- MPS: The sensor detected methane's presence within 12 seconds and reported an accurate LEL of approximately 50% within 20 seconds.

- NDIR: The NDIR sensor performed similarly to the MPS sensor with regard to detecting methane. It detected the gas's presence within 12 seconds and reported a fairly accurate LEL of approximately 50% within 20 seconds.

- Pellistor/catalytic bead sensor: The pellistor sensor did not detect methane's presence until the 30-second mark. It approached an LEL of approximately 50% at 42 seconds.

Butane

- MPS: The MPS sensor detects butane within 12 seconds and demonstrates a reading close to 50% LEL by 30 seconds.

- NDIR: The NDIR sensor detects butane but gives an inaccurate reading. It exceeds 50% LEL at 22 seconds and doesn’t stop rising until the reading exceeds 125% LEL.

- Pellistor/catalytic bead sensor: The pellistor sensor begins to detect the butane after 30 seconds has lapsed, though its reading is also inaccurate; it never exceeds 25% LEL.

Hydrogen

- MPS: The MPS sensor detects and reports the presence of hydrogen within 12 seconds and accurately reaches an LEL of nearly 50% by 40 seconds.

- NDIR: The NDIR sensor doesn’t detect the presence of hydrogen at all. Readings for this gas never appear.

- Pellistor/catalytic bead sensor: The pellistor sensor detects hydrogen within approximately 30 seconds but never reports it at an LEL of 50%. The highest reading is just below 40% LEL.

As demonstrated within this experiment, the MPS sensor outperforms both the NDIR sensor and the pellistor/catalytic bead sensor when detecting methane, butane, and hydrogen. It detects these gases quicker, provides more accurate identification of the gases, and displays a more accurate LEL reading.

Benefits of Smart Sensing Devices

MPS gas-leak-detection technologies represent the next generation of combustible gas detection and as previously shown, they outperform other gas-detection sensors.

With TrueLEL technology, MPS detectors can simultaneously detect up to 12 of the most common combustible gases—including hydrogen—with a single factory calibration. The accuracy of MPS sensors is enhanced by integrated compensations for temperature, pressure, and humidity. Gas-concentration reports remain accurate across a wide range of environmental conditions, from −40 to 75°C and 0 to 100% relative humidity. They even perform well across rapid changes in conditions.

The accuracy and reliability experienced with an MPS sensor exceeds legacy gas-detection technology, including NDIR and pellistor sensors. In addition, MPS sensors work well with just one factory calibration and never require field calibration. A single calibration can provide stable, reliable results for years.

Unlike pellistor sensors, MPS sensors don’t drift, decay, or poison. If the sensor becomes faulty or malfunctions, it will let users know immediately, reducing the risk of entering an undetected hazardous environment. The measurements are reliable and accurate, reducing costly false alarms.

Despite the major performance advantages, the MPS sensor remains an affordable option. And since it requires no maintenance over its lifetime and rarely needs recalibration, the total cost of ownership is much lower than the alternatives.

Conclusion

MPS gas-detection technology represents a tremendous leap forward in the capabilities of gas-detection sensors. MPS sensors overcome the limitations of both NDIR and pellistor sensors while offering a greater level of flexibility. They’re more accurate and reliable across nearly all environmental conditions, which is critically important when working with flammable and combustible gases. And they help create and maintain a safe workplace as well as save lives by alerting personnel to the presence of flammable or combustible gases in their environment.