Digital Relative-Humidity Sensor IC is Accurate, Rugged—and Does Temperature, Too

What you'll learn:

- Features of the new TI relative-humidity sensor family.

- The RH sensor's dual capability of measuring temperature.

- Applications for the HDC302x family.

Temperature is the most widely measured environmental parameter—that’s not news. But relative humidity (RH) also is an important parameter of the measurement scenario, often in conjunction with temperature.

The dilemma is that while it’s possible, if necessary, to protect a temperature sensor from harsh surrounding conditions while still making a measurement (after all, you’re actually measuring thermal energy), in most cases an RH sensor must be “immersed” in, and thus subjected to, its environment. The result is that RH sensors will face harsh conditions that often affect their reliability and long-term performance. (Non-contact sensing of RH could be done indirectly using infrared arrangements or lasers—see References below for two examples—but those solutions are complicated, bulky, expensive, and obviously impractical for many applications.)

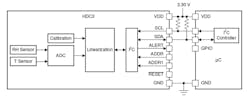

Addressing the RH-sensing challenge, Texas Instruments’ HDC302x family provides high-accuracy, low-power, digitized humidity and temperature sensing along with ultra-low drift. The company maintains this device offers the industry’s highest reliability and accuracy and the lowest power consumption—along with built-in protection of sensing elements (Fig. 1).

The design ensures and preserves data integrity under stress conditions. It’s the industry’s first to provide integrated correction to adapt to drift caused by natural aging, environmental stress, or interactions with ambient contaminants.

Applications include consumer appliances (clothes washers, dryers, refrigerators, freezers), cold-chain tracking, HVAC and environmental-control systems, humidifiers/dehumidifiers, and continuous positive airway pressure (CPAP) and ventilator systems. In automotive designs, humidity readings are needed for cabin HVAC, cabin air quality, and even particulate sensing, as well as for the battery-management systems (BMS) and on-board charger management.

The sensor has a RH operating range of 0% to 100% with typical accuracy of ±1.5%, and incorporates drift correction (a common occurrence with RH sensors) to reduce offset and return the device to its initial accuracy specification. Long-term drift is just 0.21% RH/year, and the device includes condensation protection (another common “ailment” of RH sensors) via an integrated heater.

It’s commonplace and often necessary to also measure temperature along with relative humidity. The series provides temperature readings over an operating range of −40 to +125°C with ±0.1°C typical accuracy. Both the temperature and humidity sensors are 100% tested and trimmed on a production setup that’s NIST traceable and verified with equipment calibrated to ISO/IEC 17025 standards.

The RH/temperature sensor uses an I2C interface operating at up to 1 MHz with four selectable I2C addresses, plus command/data protection using a CRC checksum. Average current requirements of this sensor, which operates from a 1.62- to 5.- V supply and comes in a compact 2.5- × 2.5-mm package, is a mere 0.7 µA.

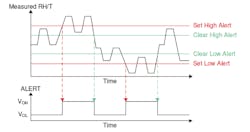

An automatic measurement mode enables humidity sensing at regular intervals to capture data while the rest of the system sleeps, further preserving system battery life in applications such as cold-chain data loggers; wirelessly connected environmental sensors like air-quality monitors, smart home, or wireless sensor nodes in buildings; or IP network cameras. In addition, an ALERT output provides a hardware notification of ambient temperature and relative-humidity measurements that violate any of four user-set thresholds, with four programmable thresholds for temperature and RH (Fig. 2).

The HDC3020 is offered in an open-cavity package without a protective cover. Two other device versions do come with a cover option to protect the open-cavity RH sensor: the HDC3021 with removable protective tape to allow for conformal coatings and PCB wash, and the HDC3022 with a permanent IP67 filter membrane cover to protect against dust and water.

The covers provide ingress protection against dust and moisture for the devices during assembly and system lifetime and help maintain accuracy when the sensor is exposed to contaminants (a common and often unavoidable situation). There’s also the HDC3020-Q1 automotive-qualified version with its own datasheet.

Pricing for the 8-lead WSON-packaged device starts at $1.65 (1,000 units). In addition to the detailed 51-page datasheet for the non-auto versions and the complementary 46-page datasheet for the auto-qualified version, TI offers some useful applications-support collateral: “Why long-term consistent performance matters for relative humidity sensors,” “How the HDC3020 Humidity Sensor Achieves Industry's Lowest Drift,” and “User’s Guide: HDC3 Silicon,” which provides storage and handling guidelines, software configuration examples, and pseudo code.

References

Bulk-Blog (Bulk Solids Handling), “Online Moisture Measurement: Non-Contact NIR Moisture Sensors in Powder and Bulk Solids.

Looking For Solutions, “Non-contact Infrared Ambient Temperature and Relative Humidity Sensors.”