The Essentials of Capacitor Selection in Automotive Designs

This article is part of the TechXchange: Charging Capacitors.

What you’ll learn:

- The four basic capacitor types.

- The key parameters involved in selecting the right capacitor for automotive designs.

- Advantages and limitations of electrolytic and electrostatic capacitors.

Choosing a reliable capacitor for today’s automotive electronic applications requires an understanding of both the performance characteristics of the various technologies and the operating conditions of the application. The application environment can significantly impact the actual in-circuit performance versus the datasheet specifications and will therefore be critical in determining the best performing and most cost-effective solution.

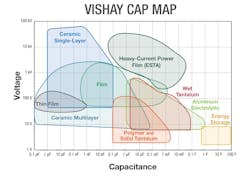

Figure 1 shows the typical capacitance and voltage ranges of popular capacitor dielectrics. Oftentimes, choices among capacitors can overlap.

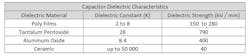

Although capacitance and voltage are usually the primary parameters involved in device selection, many others contribute to making the best choice. Figure 2 shows the typical dielectric constant (K) and dielectric strength values for four basic capacitor types.

Key Parameters Beyond Capacitance and Voltage

A combination of low K and low dielectric breakdown strength (such as is the case with poly film capacitors) results in low volumetric efficiency. However, the relatively large physical size of these devices may be acceptable, as they offer extremely low losses and stable electrical characteristics at a low cost.

When considering capacitors during operation, equivalent series resistance (ESR) is the real part of the impedance and represents losses for the capacitor in the equivalent circuit. These values vary with temperature, frequency, and dielectric type.

Insulation resistance (IR) determines the amount of dc leakage current that the capacitor passes for a given applied voltage; this leakage current is typically much lower for electrostatic (film and ceramic) capacitors. Such leakage varies with temperature and the magnitude of applied voltage, and inductance is related to the electrode styles.

Capacitor Relationships

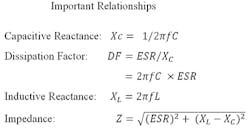

Figure 3 provides important capacitor relationships: capacitive reactance, dissipation factor, inductive reactance, and impedance. A very high value resistor is used to model IR. It’s neglected for simplicity in deriving overall impedance (Z).

Impedance is important in determining how the capacitor affects incoming signals. During charge/discharge cycles, low ESR is critical for achieving high efficiency, low heating loss, and reliability. Capacitive reactance (XC) and inductive reactance (XL) indicate energy-storage capacity and the inductive field generated by the capacitor.

Note, when XC and XL are equal, the resonant frequency of the device is achieved. This is important when choosing a decoupling capacitor to remove ac components’ noise from a dc signal. To efficiently remove ac signal components from a dc power rail, a capacitor with a resonant frequency near the frequency of the unwanted ac noise should be selected for minimum impedance and maximum decoupling to ground.

Automotive Considerations

Automotive applications are regularly divided into categories like power control (ECU and transmission) and safety and comfort (like airbags and climate control), which may be important when considering critical performance, reliability, and accuracy. Another major difference is the in-vehicle location and resulting operating conditions.

Under-the-hood applications may see salt spray, water, fuel/oil contact or immersion, operating temperatures of 125°C or even higher, and vibration levels of 15 g, up to 200 Hz. These conditions are significantly different than those in the passenger compartment. In fact, another high-capacitance technology (electric double-layer capacitor, or EDLC) is restricted to in-cabin use in applications like eLatch power backups due to its operating temperature limitations (85°C).

Types of Capacitors

In general, electrolytic capacitors (tantalum, aluminum, and EDLC) offer high capacitance but are polarized. On the other hand, electrostatic capacitors (poly film and ceramic) are non-polarized and typically exhibit very low ESR and impedance.

Tantalum devices have a recommended voltage derating of 50% for solid tantalum and 80% for polymer and wet slug axial types to preserve reliability. Surge testing/screening is required to achieve the very low ESR levels often needed for high-capacitance parts. Typical failure rates are from 5 FIT (failures per billion hours) to 15 FIT with voltage derating, and their electrical characteristics are very stable over time and temperature.

High capacitance is a key feature of aluminum capacitors. However, temperature has a significant impact on device performance and different product families are available for 85, 105, 125, and 150°C operation. There’s no need for current screening, as the devices have a useful life wear-out mechanism of up to 10 000 hours at full-rated temperature and ripple current. This lifetime can be extended by lowering either parameter.

Ceramic capacitors require no voltage derating for reliability purposes, but the voltage coefficient of capacitance must be considered. That’s because they may lose up to 40 % of their capacitance when operating on or near their rated voltage. Typical failure rates are under 1 FIT and some ranges can easily operate at 150°C. The failure mode is short or parametric shift.

Finally, poly-film devices are typically rated at 105°C, though polyphenylene-sulfide (PPS) parts can reach 125°C (polyester, or PET) or even 150°C (polyethylene naphthalate, or PEN). Voltage derating is unnecessary and typical failure rates are around 5 FIT, but surface-mount offerings are limited.

The importance of these characteristics varies depending on the application and the physical size, cost, and manufacturability desired. However, they do enable general technology selections when considering the actual circuit function.

Power filtering requires high capacitance, low ESR, and higher temperature performance, making tantalum, aluminum, and some ceramics the most applicable. Bulk energy storage requires high capacitance and low ESR for fast discharge and pulse applications.

Again, tantalum and aluminum—along with some poly films—are the most commonly used. Tuning and timing circuits require very stable capacitance across temperature and frequency and must be repeatable under thermal cycle. Here, class I (C0G/NP0 and high Q) ceramics and poly films are typically the best solutions.

Decoupling/bypass functions require very low ESR and good impedance (Z) performance. Here, ceramics, poly films, and some specifically designed tantalum polymer devices are most applicable. EMI/RFI filtering for safety class X/Y needs high voltage and pulse performance, and in these cases, film and ceramics are exclusively used.

Summary

Choosing a capacitor is a multidimensional process. Each capacitor has its own set of electrical characteristics, performance vulnerabilities, and mechanical and economic considerations. The relative importance of each of these depends on the application, environmental conditions, and the actual circuit function. Given the many choices available, it’s essential to reference each manufacturer’s specifications for the right capacitor.