Biosensors and Harvesters Go Micro—and Even Nano

Members can download this article in PDF format.

What you’ll learn

- How researchers are making use of new materials such as graphene for skin-mounted or implanted medical sensors.

- How self- or harvesting-powered devices are eliminating the need for implanted or replaced batteries.

- How techniques used in semiconductor processing are being leveraged for development of devices based non-obvious approaches.

In recent decades, we’ve seen a dramatic increase in the availability and adoption of personal medical devices for measurement and monitoring of critical body parameters. This has been made possible by a combination of ever-tinier and lower-power components, advanced algorithms, and sophisticated sensors.

Clear testimony of this is the optically based fingertip clip-on device that accurately and quickly measures blood-oxygen saturation (SpO2) in real-time (Fig. 1). This ubiquitous $25 unit has obviously obsoleted the invasive, costly, and time-consuming method of drawing a blood sample and sending it to the lab for assessment, and made DIY assessment quick, safe, and easy.

Another example is the Dexcom G6 sensor for diabetes management (Fig. 2). It attaches to the skin and accurately measures glucose levels in blood just beneath the surface, then sends data wirelessly every five minutes to a smartphone or other receiver. Plus, it’s obvious that millions of people are wearing fitness-focused smart watches that count steps, measure pulse rates, provide basic cardiac-signal monitoring, and more.

But why stop at these external sensor-driven devices, regardless of their usefulness and practicality? Researchers are increasingly looking to place nearly invisible and non-interfering biosensors onto and even into the body to enable internal, non-obtrusive monitoring of many classes of physiological parameters.

Any such effort must address three technical challenges:

- Developing the sensor itself

- Powering the system (conventional discrete batteries are obviously undesirable)

- Devising some scheme to collect and transfer the resultant data

The good news is many focused efforts are underway at various universities and similar institutions by employing a diverse range of approaches. Given the breadth of effort—and, frankly, the large amount of grant and project money that’s out there, along with graduate-degree students to help at low cost—we’re seeing an interesting range of innovation and exploration.

Many of these projects leverage technologies that have been perfected and are available due to semiconductor design, materials, techniques, and production, even if they don’t directly involve semiconductors. Materials such as graphene, a relatively recent physical embodiment of the common element carbon, also are popular “raw materials” due to their unique physical and electrical attributes.

No doubt many of these innovations will fail to “catch on” for technical or commercial reasons, but the likelihood is that others will succeed, at least to some extent. Even if they don’t do so in the formal sense, they’re often the seed from which a successful idea eventually grows. Or they’re the missing element needed for success, despite the fact that there may be no apparent, direct relationship between them.

Consider this one example: Isidor Isaac Rabi discovered the subtle fact that the spins of protons and neutrons can be made to precess in order to align with an external magnetic field (for which he was awarded the Nobel Prize in 1944). Further, when the magnetic field is turned off, these atomic particles emit electromagnetic radiation with uniquely characteristic frequencies as they return to their resting state.

However, no one jumped up at the time and said, “That’s great, now we can make a nuclear-based magnetic-resonance-imaging (MRI) system based on this obscure, deep-physics phenomena.” In fact, it wasn’t until several decades later that the MRI concept was even envisioned based on this, and then an actual MRI machine built.1

What Caught Our Attention

These 10 examples illustrate the breadth of activity, but there are many more examples:

1. Sweat for energy harvesting, and for glucose biosensing

A team at the University of Massachusetts (Amherst) has developed a microbial biofilm as a cohesive, flexible material for long-term continuous electricity production using the evaporation of water or sweat. The single biofilm sheet, about 40 µm thick, is the core functional component and continuously produces power with a density of about 1 μW/cm2—much higher than that achieved with thicker engineered materials.

Also leveraging sweat, researchers at Ohio State University successfully tested a battery-free, wireless biochemical sensor that detected the blood sugar—or glucose—humans excrete from their skin when they exercise. The topology uses a resonant circuit, which reflects RF energy sent out by an external reader system. The coupling between a sensing interface and an inductor-capacitor oscillator through a pair of varactor diodes converts a change in electric potential into a modulation of the capacitance, resulting in a quantifiable shift of the resonant circuit.

More at: Go Ahead and “Sweat It” for Energy Harvesting and Biosensing

2. Graphene-based blood-pressure sensor

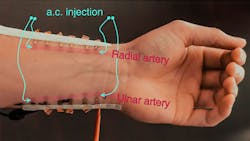

Texas-based researchers developed a graphene-based, wrist-placed electronic tattoo that delivers continuous blood-pressure measurements at an accuracy level exceeding nearly all available options on the market today. The continuous monitoring by the e-tattoo allows for blood-pressure measurements in all kinds of situations, including at times of high stress, sleeping, and exercising.

The device makes its measurements by injecting an ac current into the skin and then analyzing the body's response to determine bioimpedance. Their research created a machine-learning model to get accurate blood-pressure readings despite the complex relationship between bioimpedance and changes in blood pressure.

More at: Graphene “Tattoo” Delivers Continuous Blood-Pressure Monitoring

3. Wireless printed inductive stent

Using precision additive printing, a Georgia Tech team devised a battery-free inductive, implantable stent for monitoring blood flow that can be read non-invasively. Their fully printed pressure sensors function as a resonant LC-tank circuit and change dimensions with blood-flow pulsations, thus shifting their resonant frequency—a shift that can be detected wirelessly.

They used a laser-machining process to form a multimaterial inductive stent to enable wireless connectivity while maintaining critical stent dimensions (approximately 1 mm diameter with a bending radius of 0.25 mm). The soft pressure sensors are subsequently printed using an aerosol jet and then conformally integrated with the stent.

More at: Printed Inductive Stent + Sensor Captures, Reports Blood-Flow Data

4. Glucose-based battery

Researchers at MIT and two Swiss-based institutions have combined an ultra-thin ceramic substrate and glucose solution to create a flexible, high-capacity biocompatible battery. The cells are just 400 nm thick and generate about 43 µW per square centimeter. They also can withstand temperatures up to 600°C, well beyond the level needed to remain stable through the high-temperature sterilization process required for all implantable devices.

The three-layer design has a top anode, a middle electrolyte, and a bottom cathode. The anode reacts with glucose in bodily fluids, transforming the sugar into gluconic acid and releasing a pair of protons and a pair of electrons. The middle electrolyte acts to separate the protons from the electrons, conducting the protons through the fuel cell, where they combine with air to form molecules of harmless water. Finally, the bottom layer provides electrical connectivity.

More at: Sugar isn’t so Bad: Fuel-Cell Patch Harvests Body’s Glucose

5. Magnetoelastic sensor also provides harvesting

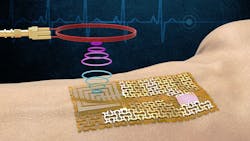

By implementing the subtle magnetoelastic effect in soft materials—ME is the change of a material's magnetic property under mechanical deformation (strain) and the inverse of magnetostriction—UCLA researchers created a flexible patch that functions as a skin-attached biosensor and energy harvester, along with a wireless link to a smartphone.

The team used microscopic magnets dispersed in a paper-thin silicone matrix to generate a magnetic field that changes in strength as the matrix undulated. As the magnetic field’s strength shifts, electricity is generated and can be harvested, while the amount of current also can act as a sensor

The team built a small, flexible magnetoelastic generator (MEG), about two centimeters square, comprised of a platinum-catalyzed silicone polymer matrix (polydimethylsiloxane) and liquid-metal coils of neodymium-iron-boron nanomagnets in a spiral-like arrangement as a magnetic induction layer. Their device generated current of 4.27 mA/cm2.

The researchers were able to extract key cardiovascular parameters from a skin-attached MEG such as pulse wave velocity and K value; upstroke time and stiffness index; and radial augmentation index and left ventricular ejection time.

More at: Subtle Magnetic Effect Leads to Bioelectronic Sensor Plus Energy Harvesting

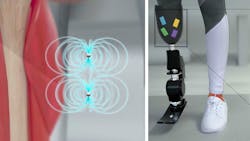

6. Magnetic muscle/joint measurement

Using tiny muscle-implanted magnets and an on-surface sensing array, researchers at MIT devised a highly accurate limb-orientation and motion sensor. They demonstrated real-time muscle-length tracking via tiny, implanted magnetic beads and external wireless sensing of their fields. It determined relative positioning needed to obtain critical feedback for continuous tracking of muscle-tissue length changes.

The magnetic beads are just 3 mm in diameter and were inserted at least 3 cm apart. Using an array of magnetic sensors placed on the outside of the legs, the researchers found that they were able to determine the position of the magnets with a precision of 37 µm as they moved a joint, and it was done within 3 ms. To sense the implanted magnets, they built custom magnetic-sensing arrays with 96 sensors to minimize implant size while maintaining acceptable tracking accuracy.

More at: Implanted Magnets, Tracking System Provide Wireless Sensing of Prosthetics

7. Nanowires and neuromorphic devices for autonomous organism functionality plus ambient harvested energy

A research team from the University of Massachusetts (Amherst) created an electronic microsystem that can intelligently respond to information inputs without any external energy input, much like a self-autonomous living organism. The neuromorphic microsystem, constructed from a novel type of electronics that processes ultra-low electronic signals, incorporates a novel device that’s able to generate electricity “out of thin air” from the ambient environment. (A neuromorphic device is an electronic analog circuit that mimics the neurobiological architectures present in the nervous system.)

Protein nanowire memristors were harvested from bacteria and fabricated on a flexible substrate. In one experiment, they developed a protein nanowire sensor that responded only to “instant” RH change. This was used to convert respiration into spiking signals as a frequency-driven neuromorphic interface.

More at: Biocompatible Protein Nanowires Create Neuromorphic Devices—and Harvest Humidity

8. Tiny implantable O2 sensor

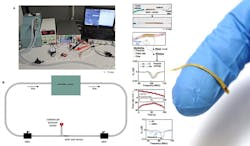

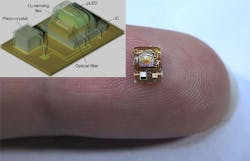

The widely used optical blood-oxygen saturation sensor can only measure this parameter in the circulatory system just below the skin. However, doctors need to monitor that oxygen parameter deep inside the body to assess the health of transplanted organs or tissue to provide an early warning of potential transplant failure. Researchers at the University of California-Berkeley created a tiny, non-RF wireless implant that can provide real-time measurements of tissue oxygen-saturation levels deep underneath the skin.

They developed the implant with a volume of just 4.5 mm3 (critical for injectable implants), powered by ultrasound energy waves. Despite its array of component types, the entire implant is manufactured with standard medical-implant processes.

An external ultrasonic transceiver directs energy from outside of the body toward the implant, which has a piezoelectric crystal for energy collection and communication coupled to a luminescence sensor for O2 detection. This wireless link is an acoustic link that powers the sensor via piezoelectric-effect harvesting, and it supports bidirectional data transmission.

More at: Deep-Implantable Blood-Oxygen Sensor Blends Multiple Sophisticated Technologies

9. Flexible supercapacitors for body-based energy harvesting

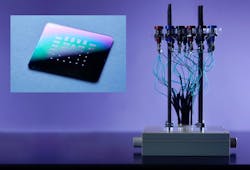

The physical rigidity of supercapacitors makes them an unsuitable option for applications that use the body’s motion as the energy source. On that front, a research team based at Pennsylvania State University (Penn State), along with members from two Chinese universities, devised and tested planar micro-supercapacitor arrays (MSCAs).

They used non-layered, ultra-thin zinc-phosphorus nanosheets and 3D laser-induced graphene foam—a highly porous, self-heating nanomaterial—to construct the island-bridge design of the cells. Then they arranged cells in a serpentine, island-bridge layout that allows the configuration to stretch and bend at the bridges, while reducing deformation of the micro-supercapacitors (the islands).

The team saw significant improvements in electric conductivity and the number of absorbed charged ions. In addition, they integrated stretchable MSCAs with a “crumpled” Au-based triboelectric nanogenerator (TENG) plus a stretchable, crumpled graphene-based strain sensor to demonstrate a self-powered, energy-harvesting stretchable system.

More at: Flexible Supercaps Enable Body-Sensing Harvesting-Powered Apps

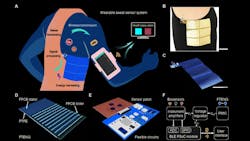

10. Triboelectric harvesting powers sweat-sensing patch

The triboelectric effect—electricity generated by the friction of motion between two suitable materials—is widely known and can generate tiny but useful amounts of energy to power body-mounted devices and their sensors. However, these energy harvesters require complex fabrication steps and lack ruggedness or flexibility for normal body wear and normal associated normal wear.

Addressing those issues, researchers at the California Institute of Technology (Caltech) developed a wearable sweat sensor that’s powered by a simple-to-fabricate triboelectric harvester, which is based on a thin sandwich of materials (Teflon, copper, and polyimide) attached to the person's skin.

As the person moves, these sheets of material rub against a sliding layer made of copper and polyimide to generate small amounts of electricity. Instead of using exotic materials, they used commercially available flexible circuit boards, which are cheap, durable, and mechanically robust over long periods of time. The team used their harvester to power an integrated, skin-attached sweat sensor that also includes a Bluetooth-based data link.

More at: Simple Yet Robust Triboelectric Harvester Powers Sweat-Sensing Patch

Reference

1. EE World, “MRI, Part 2: Historical development (and lawsuits)”