Inductive Position Sensors Solve the New Stray Magnetic Field Problem

What you’ll learn:

- Impact of stray magnetic fields on the electrification of motor vehicles.

- The role of inductive sensors to reduce risk, cost, and size in EMI-laden applications.

The clean and efficient design of hybrid and electric vehicles, from an increasingly growing number of suppliers, draws the attention of many as they drive the movement toward sustainable solutions through the electrification of motor vehicles. With the introduction of a variety of electric motors and batteries, an old problem manifests itself at a high level in the electronics world: stray magnetic fields.

Such electromagnetic interference (EMI) wreaks havoc on current popular position-sensor solutions lacking an inherent immunity, e.g., Hall-effect sensors, or those that can have immunity but are costly to implement, like magnetic resolvers and linear variable differential transformers (LVDT). Ergo, the introduction of the inductive position sensor, which provides high-accuracy position sensing despite being immersed in a stray-magnetic-field-rich environment.

Magnetic fields aren’t an unknown artifact or even a newly discovered element in the semiconductor and electronics world. They’re part of the integral function of semiconductors and considered in the design of every chip.

What’s the Impact of Motors and Batteries in EMI Generation

However, when brushless direct-current (BLDC) motors, permanent-magnet synchronous motors (PMSM), motor currents, or large battery currents are in proximity to electronics modules and sensors, the stray magnetic fields cause interference and may even induce failures in safety-critical applications.

BLDC and PMSM motors are some of the most common drive motors used in electric and hybrid two-and four-wheel vehicles. They use very strong magnets on the rotor and function when currents flow from the motor controller and are applied to the stator to activate the electromagnets. Both the magnets and the currents used in the motor emit EMI into the areas around them.

Other BLDC motors are present in many areas of a vehicle, including brake and steering motors. Also critical to the design of all electric vehicles and a contributor to the presence of stray magnetic fields are batteries—more specifically, the source of the EMI being the electrical current that flows when high currents are charging the batteries or powering the vehicle. Some vehicles use several thousand batteries to send current to the system, which makes them a major contributor to the stray magnetic fields that cause problems in traditional sensor solutions.

Hall-Effect Sensors: A Popular Yet Vulnerable Solution

Position sensing is a critical part of the design of many electronics, including those found in various applications within vehicles, such as foot pedals, throttle control, brake positioning, transmission tracking, infotainment knobs, gear shifts, steering sensors, and more. Historically, magnetic resolvers, linear variable differential transformer (LVDT) sensors, and Hall-effect sensors have been used as the main method of position sensing.

Hall-effect sensors, one of the most widely implemented solutions, are designed to determine the strength and the direction of a magnetic field, and thus able to determine the position of a magnet or electromagnet placed near to the sensor. The sensing portion of this device is a thin piece of silicon, which when exposed to a magnetic field will push electrons and holes to opposing edges of the silicon. This creates a very small voltage potential known as the Hall effect and requires strong magnetic fields to produce a sensing environment.

When EMI is added into the equation, Hall-effect sensors face the danger of distorted, premature, or false magnet detection and can risk permanent damage. To reduce the risk of failure caused by EMI, the use of magnetic absorbing metals is implemented to shield the sensor from stray magnetic fields, which increases the size and cost of the solutions.

The Inductive Position Sensor: A Game-Changer in EMI-Rich Environments

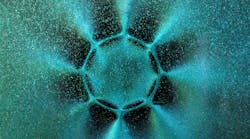

An increasingly popular solution to reduce risk, cost, and size in EMI-laden applications is the inductive position sensor. These sensors aren’t magnetic, nor do they need to use magnets or magnetic metals, but they are—as the name suggests—an inductor-based solution (see figure).

Through the design of the sensor body, which is a thin PCB with an embedded winding of metal traces, passive rejection of EMI is achieved. As a conductive piece of metal, called a target, is passed over the sensor, the magnetic fields emitted by the primary coil on the PCB (similar to the primary on a transformer) are disrupted and the magnetic field drops to zero where the target is located.

Also embedded in the PCB are two receive coils (secondary of the transformer) that detect the different voltages caused by the disturbance of the magnetic field. The resultant information is processed at the IC to return the position-based output value to the system. Built into the design of these devices are the key methods to reject stray magnetic fields that would normally interfere with the system.

Noise Filtering in Inductive Position Sensors

Active and passive noise filtering are some of the key features implemented by design in many inductive position sensors.

Active rejection of stray magnetic fields is achieved through the well-known technical properties of synchronous demodulation and bandwidth filters. Combining these techniques allows for specific signals to be measured, while ignoring the otherwise intrusive noise from the environment. The transmitter and receiver originate in the same system and thus we can calculate the exact phase between the two signals and actively reject magnetic-field noise.

Passive filtering is enabled by the voltage-detection coils. The disturbance detected on these coils can be used to calculate the exact position based on a ratio of sine and cosine. Metals outside the effective air-gap range aren’t registered in the sensing circuit due to the use of the ratio metric calculations utilizing the signals from the receive coils. Implementing these noise-rejection methods provides highly accurate position detection that’s immune to stray magnetic fields while removing the need for heavy and expensive magnets, or EMI shielding.

EMI Experiments

In support of these claims of incredible EMI immunity, the team at Microchip Technology collected evidence through experiments on the inductive position sensors with induced magnetic fields close to the sensor.

In one experiment, a neodymium magnet was placed approximately 15 mm above the linear PCB sensor body using an acrylic structure in such a way that the target would pass freely under the magnet. Moreover, the magnet could be moved statically or dynamically along the sensor body. A gaussmeter probe was also placed along the sensor to detect the strength of the magnet.

Although the probe detected a 7.2-mT (5716.9 A/m) magnetic field, there was no influence on the precise sensing of the target’s position as it was moved along the PC. Other tests, according to ISO11452-8 automotive standards, prove the immunity levels of these encoders meeting level IV and even surpassing those levels to achieve a 7,000 A/m (8.8 mT) electromagnetic conductance immunity at a 10 Hz.

The inductive encoder technology consistently performs without interference despite magnetic fields being forced into the sensor. The accuracy and precision of the target detection isn’t diluted or distorted due to the synchronous demodulation and the operating frequency of the IC design.

Conclusion

As modern design requirements demand a continually shrinking form factor while maintaining or improving performance, the inductive position sensor lends itself as a fantastic upgrade to aging magnetic solutions. The same IC can support linear and rotary position-sensing designs using a simple PCB sensor body and a small metal target. This solution is immune to stray magnetic fields while maintaining very high accuracy, and it’s able to support high-reliability (AEC Q100 Grade 0) and safety-rating (ASIL D) standards.

Pushing ahead in this movement to inductive position sensing, Microchip has developed a wide array of these sensors that support a plethora of low- and high-speed sensing applications, including motor control. These sensors are well-suited for precision position sensor designs, including those where high levels of magnetic interference is present.