Specialized Circuit Drives 150-V Piezoelectric Motor Using Low-Voltage Op Amp

This file type includes high resolution graphics and schematics when applicable.

A piezoelectric motor is a linear motor with bidirectional motion. It uses friction to grip the armature while a voltage is ramped to warp the piezoelectric material and move the armature. The voltage then is quickly removed.

As the material springs back, it breaks away from the armature and returns to its zero position, leaving the armature a few micrometers further along its track. Repeat this at a kilohertz rate and for thousands of times. While each of the motions is very small, after several seconds you may see that the armature has moved, if you look carefully. (Full disclosure: I had never heard of piezo motors before being asked to make a driver for one.)

Related Articles

- Piezoelectric Motor Delivers Precise Positioning In Small Applications

- Drive Piezoelectric Actuators With Fast, High-Power Op Amps

- Piezoelectric Ceramics: Science Meets Pottery

There are two drive waveforms, one for forward and the other reverse: a sawtooth waveform with a slow linear rise followed by a fast fall, and its complement with a fast rise and slow linear fall. This was done using an op-amp triangle-wave oscillator at 1 kHz, with diodes switched in to speed up either the rising or falling edges to about 5% of the cycle. The driver’s required bandwidth is only 10 to 15 kHz.

The problem is the voltage. Fortunately, it is unipolar. Unfortunately, it is +150 V(peak). The required current is quite small. It has to be only enough to charge and discharge the 20-nF piezo element. A calculation using charge transfer (Q) shows that during the ramp phase:

Q = It = CV

where:

t = 1 ms

C = 20 nF

V = 150 V

therefore:

I = CV/t = 3 mA

A 600-mW boost converter can be used to switch the +12 V up to +200 V with a 3-mA load requirement. The most straightforward circuit uses an op amp rated to at least 200 V. While some op amps are available with this voltage rating, they are meant for high-current applications and are quite expensive.

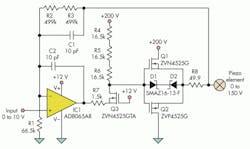

The circuit in the figure is much cheaper and based on a common op amp used as a non-inverting amplifier. The heart of the circuit is the current mirror of R7, N-channel FET Q3, and series-connected R4, R5, and R6. (The reason for using three resistors in series is explained below.)

With Q3 in a common-gate configuration and the gate at +12 V, its source voltage remains reasonably constant at +10 V (from +12 V less the Vgs(on)). Any output of op-amp IC1 less than that +10 V causes a voltage drop across R7, with the current coming from R4 to R6. Since R7 has the same current as R4 to R6, there is a voltage gain of the ratio of (R4 to R6)/R7 or 33. The voltage at the bottom of R4 to R6 (the Q3 drain) now has the required voltage swing but a high impedance.

A pair of complimentary FETs acts as followers to lower the output impedance and boost current output. Negative feedback is provided via R2 and R3, along with bandwidth limiting by C1. The overall closed-loop gain is set by (R2 + R3)/R1 + 1 = 16.

There are a few subtleties to the circuit. If something happened to the piezo motor, such as the user shorting it, Zener diodes D1 and D2 would protect the FET gates. The current-mirror high-side resistance provided by R4 through R6 is split into three distinct devices to handle the power levels so 0805/2012 surface-mount (SMT) resistors can be used. The feedback resistance composed of R2 and R3 is split into two devices to reduce the voltage coefficient of resistance. This is a somewhat obscure effect, where a component’s resistance actually changes slightly at higher voltages.

There is a small feedback capacitor directly on the op amp to provide stability. Without it, the parasitic capacitances (most notably the Miller capacitances Cdg and the piezo’s capacitance) would cause enough phase shift for the op amp to oscillate. Crossover distortion is not a problem because the piezo element could not react to that bandwidth and does not require a perfect waveform.

Another problem would be the infinite pole caused by a purely capacitive piezo element. By taking the feedback directly from the sources of Q1 and Q2, resistor R8 would add a more deterministic pole to the load and increase loop stability.

Once the somewhat finicky piezo motor was adjusted, the final circuit worked well. The armature would move back and forth with incredibly fine resolution.

Alan Stummer designs electronics for the University of Toronto’s quantum optics and pulse laser research labs, after years working on analog controls for heavy industry and then telecom. He can be reached at [email protected].