Achieving Ultimate Fidelity with Advanced Motion Control—An Engineer’s Perspective

The Dereneville Modulaire MK III crafted by AVDesignHaus is considered the best turntable in the world (Fig. 1). Although the investment for this fine system might be extremely high, audiophiles love it and will appreciate the excellent value it offers. The complete deck comes with a polished Corian chassis, high-efficiency shock absorbers for enhanced stability, and a heavy, magnetic, contactless bearing turntable.

1. The Dereneville Modulaire MK III turntable with DTT-01 linear tracking tonearm. (Source: AVDesignHaus)

While all mechanical parts are precision, handmade unique pieces, making the turntable almost look like a Department of Defense scientific instrument, smart microelectronics controlling the system's electromechanical components are responsible for the "last mile" of sound quality. Its major characteristic—stunningly pure, clear sound output—is made possible by the new fully automatic Dereneville DTT-01-S active linear tracking tonearm. It’s actuated by stepper motors and electromechanically controlled by the latest generation of smart stepper-motor driver chips developed by TRINAMIC Motion Control.

This article discusses the challenge faced by the engineers while following their goal to design the perfect tonearm for the turntable system, and how a smart piece of motion-control silicon overcame this challenge by totally silencing the system's electromechanical actuators.

AVDesignHaus's Engineering Challenge

Every analog audio enthusiast's dream is to experience clear high-fidelity sound with perfect trebles and without distortion when listening to their favorite tracks.

But in an analog deck, many factors distort the original track information, such as the lateral tracking angle error of the headshell and the stylus, mechanical vibrations within the whole system, or mechanical stress at the stylus and the record's groove. Higher audible frequencies and the record's inner grooves are especially susceptible to these factors. Since the theory of record operation is based on the smallest micro-dynamic vibrations, even the smallest deviations are absolutely performance-disturbing.

With an increasing lateral tracking angle error, the total harmonic distortion of the sound output increases. This results in, among other things, diminished precision and reduced ability to locate single voices or instruments.

Technically, the goal is to scan the original recorded vinyl track information with the stylus in a 90-degree angle of the groove and in optimal tangential alignment to the center of the record, exactly as it has been cut and pressed during the record's manufacture. And it must be done without adding noise, without misreading information, and with minimal mechanical wear of the components.

While there are nearly perfect solutions to electronically amplify the audio signal once it’s read by the tonearm's stylus, the stylus' physical and electromechanical task of perfectly scanning the vinyl's groove information is the engineer's challenge.

Conventional tonearms suffer from radial mounting and lack active positioning. They passively follow the record's track, leading to skating and lateral forces. In contrast, active linear tracking tonearms actively position the stylus on the groove while maintaining a tangential orientation with regard to the disc's center.

The Dereneville DTT-01-S tonearm relies on a linear drive based on hybrid stepper motors; the headshell itself is gimbal-mounted. Using precision laser optics and an advanced control algorithm, the 90-degree angle of the stylus is permanently captured and maintained. The control unit regulates the movement of the linear drive and the stepper motors accordingly. Stepper motors are ideally suited for this positioning task since they directly hold the commanded rotor position without needing additional feedback and regulation.

A large portion of vibration and resonance within the analog deck are dampened or removed completely by the heavy chassis, air and magnetic suspension, and high-quality bearings. These primarily focus on overall stability and protection from external forces.

Nevertheless, the electromechanical components of the active linear tracking tonearm—small stepper motors—induce vibration directly at the fixture of the tonearm, which passes on to the headshell and the stylus. This adds noise, makes the headshell jolt, and reduces audio signal quality.

But where do these additional vibrations come from when using stepper motors?

Where Does the Noise Come From?

Stepper motors are widely used in nearly all kinds of moving applications in automation, digital manufacturing, and medical and optical appliances.

Their advantages are comparatively low cost, high torque at rest and at low speeds without using a gearbox, and inherent suitability for positioning tasks. Stepper motors don’t necessarily require complex control algorithms or position feedback to be commutated, in contrast to three-phase brushless motors and servo drives.

Their downside has been high noise levels, even at low speeds or at rest. Stepper motors have two major sources of vibrations: step resolution, and side effects that result from chopper and pulse-width-modulation (PWM) modes.

Step Resolution

Low-resolution step modes like full- or half-stepping are the primary source of noise. They introduce tremendous vibrations that spread throughout the whole mechanics of a system, especially at low speeds and near specific resonance frequencies. At higher speeds, these effects decrease due to the moment of inertia.

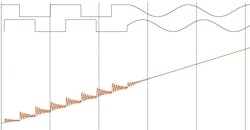

2. The plot shows reduction of motor vibrations when switching from full stepping to high microstep resolutions. (Source: TRINAMIC Motion Control)

With modern control processes and careful layout, these motors can operate virtually silently. The best way to reduce acoustic emissions is to reduce resonance and mechanical vibrations, by increasing step resolution using smart drivers. Smaller steps, called "microstepping," smooth motor operations, greatly reducing resonance (Fig. 2).

Microstepping divides one full step into smaller pieces, or microsteps. Typical resolutions are 2 (half-stepping), 4 (quarter-stepping), 8, 32, or more microsteps. The maximum resolution for microstepping is defined by the driver electronics' analog-to-digital and digital-to-analog capabilities.

Chopper and PWM Modes

Another source of noise and vibration originates from the parasitic effects of conventional chopper and PWM modes typically used with stepper motors. These effects are often neglected due to the dominant impact of coarse step resolution. But with microstepping, these effects become apparent and even audible.

The classic constant off-time PWM chopper mode is a current-controlled PWM chopper that works with a fixed relation between fast decay and slow decay phases. At its maximum point, the current reaches the specified target current, resulting in an average current that is lower than the desired target current.

In a full electrical revolution, this results in a plateau around the zero-crossing area of the sine wave when the sign (direction) of the current changes. What’s the impact of this plateau? Actually, there’s a small period with zero current in the motor windings, meaning there’s no torque at all, which leads to a wobbling behavior and vibrations, especially at lower speeds.

Going a Step Further: Totally Silencing Stepper Motors

The TMC5130A-TA—a small, smart stepper-motor driver and controller IC that includes StealthChop mode—was the ultimate solution for this remarkable analog record player.

Trinamic's stepper-motor controller and drivers allow a stepper motor with up to 256 (8-bit) microsteps per full step. Using such a high microstep resolution means the motor's rotor is now stepped in much smaller angles, or smaller distances, reducing oscillation and thus noise.

While microstepping reduces a large part of the vibrations caused by low step resolutions, other sources of vibrations become more perceivable when using high microstep resolutions. Advanced current-controlled PWM chopper modes like Trinamic's SpreadCycle, for example, already reduce vibrations and wobbling to a large extent, sufficient for many standard applications and well-suited for higher-speed applications.

Nevertheless, even with current-controlled chopper modes like SpreadCycle, which is implemented in hardware, there's still some audible noise and vibration due to unsynchronized motor coils, regulation noise of a few millivolts at the sense resistors, and PWM jitter. This can be critical for high-end applications, slow- to moderate-speed applications, and anywhere noise is unacceptable

For the Dereneville DTT-01-S linear tracking tonearm it was intolerable, because the noise coming from the microstepping drive and hybrid stepper is superimposed on the audio signal, especially within the plain grooves at the transition between individual tracks.

Without introducing additional vibrations, Trinamic's StealthChop algorithm, also implemented in hardware, ultimately silences stepper motors by following a different approach compared to current-based chopper modes like SpreadCycle. It’s responsible for the noiseless, smooth movement of the tonearm and stylus.

When combining that with closed-loop tracking angle regulation and precision laser optics, it results in a maximum tracking angle error for headshell plus stylus of <0.05 degree. A good conventional pivoted tonearm has a typical tracking angle error of <2-3 degrees and furthermore suffers from skating forces and mechanical wear of the groove.

StealthChop's technology is voltage chopper-based. Trinamic has improved voltage-mode operation and combined it with current control. Based on the current feedback, the TMC5130A-TA chip's driver regulates voltage modulation to minimize current fluctuation. As a result, the system can self-adjust to the motor's parameters and the operating voltage. Small oscillations caused by the regulation algorithms of direct-current control loops are eliminated.

Motor drivers equipped with StealthChop combine current waveforms that closely replicate analog with minor improvements in power consumption at no additional cost. The result is whisper-quiet motion.

StealthChop delivers exceptionally quiet stepper-motor performance, except for the noise from ball bearings, which can’t be changed. StealthChop applications have achieved noise levels of 10 dB and more below classical current control. As we know from physics, a change of −3 dB represents a decrease of approximately half the noise or sound level.

Alternative Technology Solutions

To solve their tonearm noise problem, the AVDesignHaus engineers first looked at mechanical solutions such as different types of bearings and different methods for mounting the tangential tonearm. When none of these worked, they decided to redesign the tonearm in search of absolute quiet, trying several different drive concepts: a linear drive, a toothed-belt drive, and a trapezoidal spindle with a polymer nut. Each brought small improvements, but not enough for the quiet they sought.

On the electrical side, they started with Trinamic's TMC260-PA stepper-motor driver using 256 microsteps and its current-based chopper mode, SpreadCycle. It didn't solve the challenge. The engineers then assumed that, instead of the 200 full-step motor they began with, driving an 800 full-step stepper motor would be sufficient. However, the vibrations produced by the motor's stepping were still too strong and became audible in the audio output signal.

Finally, they went back to the 200 full-step motor using 256 microstepping in combination with StealthChop, implemented in the TMC5130A-TA stepper-motor driver and controller.

Conclusion

The new fully automatic tangential tonearm Dereneville DTT-01-S as used in the remarkable Dereneville Modulaire MK III analog turntable truly is the first of its kind. It redefines the standard in the analog hi-fi world.

3. Here’s the final controller PCB for the electromechanical actuators of the tangential tonearm DTT-01-S, along with Trinamic's smart stepper-motor driver solutions. (Source: AVDesignHaus)

The tonearm relies on the TMC5130A-TA stepper-motor driver and controller (Fig. 3). This smart IC with StealthChop mode for ultra-silent stepper motor operation—no audible noise and no physical vibrations—adds the necessary final touch to this perfect piece of engineering, and is responsible for the pure sound output audiophiles love to hear.

While the manufacturing volumes might be relatively low in terms of the IC business, many comparable applications can take advantage of this technology. One example is wafer handling in semiconductor manufacturing equipment, medical applications, and lab automation. These share similar quality requirements for low noise and vibration.

Dr. Stephan Kubisch is Head of R&D at TRINAMIC Motion Control GmbH & Co. KG.