Radar-Focused Voltage-Controlled SAW Oscillators Feature Ultra-Low Phase Noise

Voltage-controlled oscillators (VCOs) have a difficult challenge. On one side, they need to be stable with low values of detrimental characteristics such as phase noise, jitter, and drift. On the other side, they must be adept at having their operating frequency determined and shifted by a controlling voltage—and be able to maintain that frequency.

Depending on the intended operating frequency, there are different ways to implement a VCO. For several decades, one technology has used surface-acoustic-wave (SAW) energy as the critical oscillator-circuit element.

Ovenized 320- and 400-MHz VSCOs

Addressing the need for specialized VCOs, Microchip Technology introduced the 101765-320-A family of oven-stabilized, voltage-controlled SAW oscillators (dubbed VCSOs) designed to deliver ultra-low phase noise and operate at 320 MHz (Fig. 1). A 400-MHz 101765-400-B version is also available with similar specifications but some important differences.

The SAW resonator is a high-Q quartz device that enables the circuit to achieve ultra-low phase noise, while the patented micro–oven technology stabilizes performance over the operating temperature range and consumes minimal power. These devices are targeted at radar and instrumentation systems such as active electronically scanned arrays (AESAs) that demand high fidelity in phase-locked-loop timing.

(Note that “VCSO” is one of those tricky “layered” acronyms, as it embeds only the first letter of one acronym—in this case, “SAW”—into the larger one, a combination that can be somewhat confusing. But it’s industry-standard nomenclature, so we won’t ty to fight it.)

Minimizing Phase Noise

Phase noise—undesirable energy near the output frequency—is measured in the frequency domain. It’s usually expressed as a ratio of signal power to noise power measured in a 1-Hz bandwidth at a given offset from the desired signal. Low phase noise is crucial for improving the lower limit of detection in radar and other sensing applications.

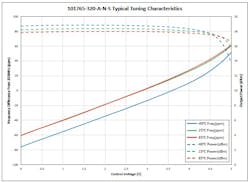

The oven-stabilized (“ovenized”) 101765-320-A VCSO delivers nominal single-ended output power of +18.5 dBm with ultra-low phase-noise performance of −166 dBc at 10 kHz offset and a −182-dBc floor. The VCSO control voltage is between 0 and 4.5 V (Fig. 2).

The new VCSOs are available in a 1.0- × 1.0- × 0.2-in. high, 16-lead, surface-mount, hermetic Kovar package. It’s not RoHS compliant as Sn63Pb eutectic solder is used in assembly for tin whisker mitigation. (If you’re not familiar with it, Kovar is a metal alloy comprised primarily of iron, nickel, and cobalt; it’s used for glass-to-metal seals that require a matched expansion between metal and glass or ceramic.)

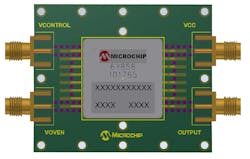

The units operate from supply voltages between 4.75 and 15.75 V and a supply current of 111 mA. The integral oven has its own package connections and requires a 9- to 15.75-V supply at 25 mA (steady-state). Microchip also offers a basic FR-4 test board (suffix -TB) measuring 2.250 × 1.875 in., which brings the package pins out to SMA connectors (Fig. 3).