Whether you’re designing integrated circuits, equipment, or systems, you absolutely must provide protection from electrostatic discharge (ESD). ESD is a common problem in most environments. Product failures from ESD lead to enormous reliability issues that can increase costs, drive customers away, and give your products a poor reputation.

Designing in ESD protection may be a boring process, but it’s an essential part of creating new circuits or equipment today. It’s one of those things that you don’t have to like, but need to do if you’re going to avoid having your products labeled as a catastrophe. The good news is that multiple solutions are available to make adding ESD protection fast and easy.

Explaining ESD

ESD is that sudden transfer of static electric charges from one object to another, where each object has a different electrostatic potential. Almost all objects will pick up a charge of electrons when it touches some other object. Walking on a carpet will cause you to pick up a charge of many volts that will be felt as a momentary shock when touching some nearby metal object. Handling anything plastic, such as a Styrofoam cup or plastic bag, will cause a charge build up.

This difference of charges represents hundreds or even thousands of volts. When the two objects with different charges are brought together and touch, the resulting transfer of electrons produces a high current flow. The results are thermal levels that can melt material or the breakdown of dielectrics in an IC. The outcome is usually a catastrophic failure of semiconductor devices.

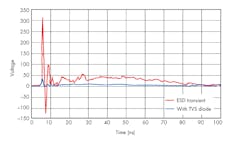

1. Shown is a typical ESD transient pulse and how it can be suppressed with a TVS diode.