The Internet of Things (IoT) is a huge innovation area for electronics and electronic design. From the cloud to gateways/servers/routers and individual sensor nodes, many breakthroughs have occurred and continue to occur to make this ecosystem work well together. The goal is to be efficient in terms of both power and data transfer.

This file type includes high resolution graphics and schematics when applicable.

Related

The individual sensor node is arguably the most interesting component of this system since it encompasses so many different sensors and applications. From the smart thermostat in your office adjusting the room temperature or humidity based on tomorrow’s weather forecast to your smart watch reporting the past week’s power consumption profile of that same thermostat, the possible use cases encompass every conceivable nook and cranny of our lives.

While the sensor nodes themselves are very diverse, the power management challenges are less so. New developments in ultra-low power management, such as higher efficiencies and greater integration, are enabling more powerful and smaller sensor nodes for the IoT.

Power Management for the IoT

The power management for each sensor node in the IoT has one basic goal: do more with less. Do more clearly refers to tasks such as connecting to the Internet, remembering past settings and user options (to learn what to do in future use cases), and offering the user a modern, easy-to-use, possibly customizable interface to interact with and control the sensor.

These functions each require new hardware and software, such as a radio, a bigger processor with new algorithms, or a certain interface like a LED display or DLP pico-projector. New hardware requires adapted or possibly completely new power management. New software, especially if it is ultra-low-power optimized software with many different power-saving or sleep modes, requires new power management to fully take advantage of the more efficient code.

With less refers to the sensor’s power source. Whether or not the sensor is powered from the line, batteries, or energy harvesting, the trend is to significantly reduce the power drawn from these sources. For any sensor in the IoT, reducing power consumption has clear and direct benefits to the end equipment and user.

Lower power requirements allow line-powered sensors such as thermostats to meet Energy Star or other efficiency standards to enable green building certifications. For sensors powered from batteries such as most wearable devices, drawing less power translates to a smaller and lighter battery pack that is easy to wear and for longer periods of time. And for energy harvesting-powered sensors, such as solar-powered window shade motors, less power consumed enables a smaller solar panel that obstructs less of the window, retaining the aesthetics of the view.

Smart Thermostat Sensor Node for Building Automation

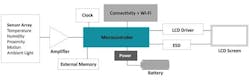

A typical smart thermostat essentially consists of a temperature-sensing element (or multiple elements), microcontroller (MCU), and connectivity (Fig. 1). The sensor measures the temperature and reports it to the MCU. The collected data is reported, via radio or wired connection, directly to the Internet or to an intermediate server. While the end result is simply turning the air conditioning, heating, or fan on or off, much more can be done with this sensor’s data. Compiling all the data from thousands of thermostats and other sensors in a building gives the complete picture of the HVAC usage and performance of that building.

Since building thermostats generally remain in fixed locations, connecting to the line for the primary power source makes much sense. This provides a very reliable, low-maintenance power source. The higher line voltage is stepped down to a lower and more useable 5-V level. From this intermediate bus voltage, the subsystems are powered. In addition to the line, a backup power source is needed to keep the thermostat operational when the line voltage fails. A primary chemistry battery, such as an AA (alkaline) or a coin cell (lithium), is the simplest solution since they are readily available and do not require charging circuits, which add cost.

The MCU typically requires around 1.8 V, but this may need to be as high as 3 V to support some functions like programming the flash or achieving a higher operating performance. As well, the MCU has a very non-uniform load profile with numerous sudden changes in load current as the code executes. This challenges the power supply’s regulation loop to keep the MCU’s voltage in regulation during these load transients. Finally, modern microcontroller sleep modes, such as the ultra-low MSP430F59xx (FRAM) with EnergyTrace++ technology,1 reduce their current draw to below 10-µA levels.

Since thermostats operate in this standby mode most of the time (between temperature checks and reporting the sensed data), the power conversion efficiency in this mode is critical to the overall efficiency of the system. An ultra-low-power optimized power supply is required to obtain decent efficiency at this operating point. The MSP430FR59xx MCUs were developed with a low-leakage process, integrated FRAM memory, and low-power peripherals to enable more functionality with the same power budget. FRAM solves problems traditionally seen with flash memory, due to its unified memory, low power, fast write times, high endurance, and more.

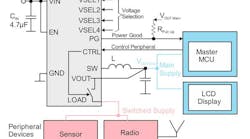

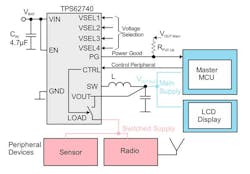

An example of an ultra-low power optimized device that fulfills these requirements for a thermostat is the TPS62740.2 This ultra-low-power step-down converter contains four digital input pins to adjust the output voltage between 1.8 V and 3.3 V. Its DCS-Control regulation topology3 supports a very fast response to load transient providing sufficient output voltage regulation.

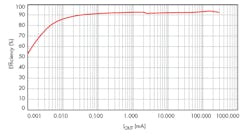

Most importantly, the TPS62740’s 360-nA operating quiescent current (IQ) enables the efficiency curve shown in Figure 2: 85% at a 10-µA load current.4 This becomes more important when the line fails and the thermostat operates from the battery. A high efficiency in this operating mode prolongs the battery’s life, so it won’t be depleted and need to be replaced for many years.

Finally, the TPS62740 integrates a load switch that is an ideal fit for the radio. By connecting the radio to the load switch and not to the microprocessor’s supply voltage, the load switch’s power can be removed when it is not needed and its leakage current eliminated from the system (Fig. 3).

Conclusion

The ultra-low IQ and higher operating efficiencies of ultra-low-power optimized power supplies, combined with their integration, enable sensor nodes in the IoT to do more with less. When the proper power management is used, these sensors can connect to the Internet or another device such as a wearable. They also can operate from backup batteries for years between battery replacements and meet Energy Star requirements when operating off the line.

References

2. TPS62740

3. DCS-Control

4. IQ: What it is, what it isn’t, and how to use it, Chris Glaser, Analog Applications Journal (SLYT412), Texas instruments, 2Q 2013

Christopher James Glaser is an applications engineer for TI’s Low Power DC/DC group. In this role, he supports customers, designs evaluation modules (EVMs), writes application notes, trains field engineers and customers, and generates technical collateral to make TI parts easier to use. He received his BSEE from Texas A&M, College Station, Texas. He can be reached at [email protected].