Production-Grade AI Arrives in EDA for Analog Design and Verification

What you’ll learn:

- The limitations of traditional SPICE simulations.

- Role of production-grade AI in transforming EDA.

- Applications of AI in day-to-day engineering.

- The future of AI in analog design.

In the realm of analog design, the demand for SPICE-level verification has outstripped the capabilities of traditional methods. This demand is driven by several factors: the increasing size and complexity of custom designs, advanced process technology introducing new considerations at the transistor model level, and the operational requirements for newer applications such as automotive and mission-critical chips.

These factors collectively push the need for highly accurate custom IC and analog verification, which must be performed at higher volumes and within shorter timeframes.

The Traditional Verification Bottleneck

Traditionally, analog design verification has relied heavily on SPICE simulations. While SPICE provides highly accurate results, it’s computationally intensive and time-consuming, making it challenging to scale with the growing complexity of modern designs. This has created a bottleneck in the design process, as verification can become a significant hurdle, delaying time-to-market and limiting the capacity for innovation.

To reinforce the challenge, every component in any new chip design or process must undergo SPICE-level verification to ensure it performs at or beyond specifications across all process, voltage, and temperature (PVT) operating corners, as well as local device variations. This is an exhaustive task without the proper tools.

For instance, achieving a 6-sigma verification target, which allows for one error in a billion samples, typically requires approximately 10 billion samples to measure with a reasonable confidence interval.

The AI Disruption

Artificial intelligence (AI) has emerged as a transformative solution in the field of electronic design automation (EDA), particularly for analog design and verification. AI technologies offer a scalable approach that significantly enhances verification speed, coverage, and accuracy, far surpassing the capabilities of traditional methods.

The integration of AI in EDA isn’t merely an incremental improvement—it represents a paradigm shift that enables engineers to tackle the complexities of modern analog design more effectively.

Meeting Production-Grade AI Criteria

Having AI technology in your solution is one thing; reaching a production-grade level is another. Production-grade AI powers tools to meet production-grade criteria: verifiability, usability, generality, robustness, and accuracy.

- Verifiability: Validating and checking that the decisions made were correct. In addition, if the verification is transparent to users, it would help them gain their trust in the technology.

- Accuracy: Fast and inaccurate don’t help. Meeting or exceeding the standards set by traditional verification methods is key; in our case, that’s the result of the brute-force simulations. This level of accuracy is essential for applications like automotive and mission-critical chips, where the margin for error is minimal.

- Generality: AI solutions need to be applicable across a wide range of design scenarios, handling diverse tasks and challenges. This generality ensures broad applicability and versatility.

- Robustness: Resilience and reliability are also important, providing consistent performance even in the face of varied and complex design challenges. This robustness maintains the integrity and quality of the verification process.

- Usability: Finally, AI solutions need to be user-friendly and easy to use. Users of EDA applications aren’t particularly AI experts; the solution needs to allow for minimal training disruption and maximum productivity.

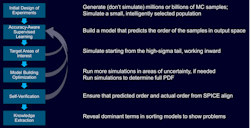

Solido AI solutions (Fig. 1) help ensure the above production-grade criteria are met to provide a powerful and seamless user experience, resulting in a faster design cycle with better accuracy and coverage. Siemens' Solido Design Environment is a pioneer in integrating AI into EDA—long before it became a mainstream approach.

AI in Day-to-Day Engineering

AI technologies have evolved to meet these criteria, achieving production-grade status and becoming integral to day-to-day engineering work. Here are some applications of how Solido's AI is utilized in custom design and verification:

- Adaptive AI: AI models can predict the behavior of custom designs under various conditions, enabling engineers to identify potential issues early in the design process. These predictive models enhance the accuracy of verification and reduce the risk of design respins.

- Automated design optimization: The AI algorithms rapidly explore the design space, identifying optimal design parameters and configurations that meet specific user-defined criteria. This accelerates the design process by reducing the need for extensive manual iterations.

- Built-in calibration and trimming: A built-in trimming and calibration capability makes it possible for the user to find the optimal trim code, automatically optimizing the user-defined targets by defining multi-testbench flows.

Transitioning from Individual Verification Jobs to Iterations

Additive AI technology is the newest generation of AI in the EDA sector. It retains AI models from base runs and stores them to be reused again with any iterative or incremental operation. This significantly reduces the number of simulations needed for subsequent runs while maintaining full accuracy. That means faster verification cycles, less engineering and computational resources, and faster time-to-market. Solido Design Environment implemented Additive AI in its latest technology, Solido Additive Learning (Fig. 2).

The Future of AI in Analog Design

The integration of AI in EDA is still evolving, and the potential for further advances is vast. As AI technologies continue to mature, they will enable custom IC and analog engineering teams to achieve innovation milestones even faster. Did someone say GenAI in EDA?

In conclusion, the arrival of production-grade AI in EDA, as demonstrated by Siemens’ Solido Design Environment, marks a significant leap forward for analog design and verification. By addressing the challenges of traditional methods and offering scalable, accurate solutions, AI is driving a new era of innovation in the field.

As AI technologies continue to evolve, they will further empower engineering teams to push the boundaries of what’s possible in custom IC and analog design.

About the Author

Mohamed Atoua

Product Manager, Siemens EDA

Mohamed Atoua is a Product Manager for Solido Design Environment at Siemens EDA with a strong background in EDA and circuit design. His journey began at Cairo University, where he earned a bachelor's degree in electrical engineering, specializing in electronics, with a minor in computer engineering. Atoua is currently pursuing his master's degree in business administration at the University of Illinois Urbana-Champaign. He thrives at the intersection of technology and management.

Atoua has 7+ years of experience in the EDA industry across different functions with a track record of blending technical solutions with business acumen. Atoua’s current mission is to help circuit designers address the challenges of meeting higher design complexity faster and with less effort through Siemens Solido Design Environment software.