Thermoelectric Devices Convert Waste Heat Into DC Power

Effective recovery of a vehicle’s waste heat by a TEG can enhance energy efficiency, reduce greenhouse gas emissions, and promote sustainable development. The effectiveness of a TEG is characterized by a dimensionless figure of merit known as ZT, which is related to the Seebeck coefficient, electrical conductivity, thermal conductivity, and absolute working temperature, respectively. The higher the ZT, the better the performance.

Related Articles

- Thermoelectric Power Generators for Energy Harvesting

- Thin Film Thermoelectric Module Product Line

- Harvesting Unused Energy with Flat Thermoelectrics

- Thin-film thermoelectric power generators harvest waste heat

- Thermoelectric Controller

A TEG usually consists of pairs of doped n- and p-type semiconductors connected thermally in parallel and electrically in series. When one of the junctions is at a different temperature than the other, a direct electric current flows in the circuit. The magnitude of the current depends on the specific thermoelectric properties of the two materials and on the temperature difference between the two junctions.

The operating temperature range of a TEG depends on the materials employed. For example, a bismuth-tellurium system is suitable for relatively low temperature operation (room temperature to 200 °C), whereas silicon-germanium alloys work best for high temperature applications (>800 °C). For moderate temperature (T = 500 to 800 °C), heat sources such as a vehicle’s exhaust and industrial waste heat, half-Heusler types are the material of choice.

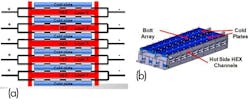

A demonstration of the TEG’s ability to convert a vehicle’s waste heat into electricity was performed for the Army’s TARDEC (Tank Automotive Research, Development and Engineering Center) program. For that program, GMZ Energy successful demonstrated a 1,000 W TEG designed for diesel engine exhaust heat recapture. The company integrated five 200W TEGs into a single 1,000 W diesel engine solution that directly converts exhaust waste heat into electrical energy, which increases fuel efficiency and lowers overall costs. Figs. 1(a) and 1(b) shows the construction and interconnections of the 1000 W TEG.

The GMZ TEGs demonstrated continuous output power with no degradation in performance over the test period. To simulate vehicle performance, the unit was tested by connecting directly to the exhaust of a 15-liter V8 diesel engine inside an engine test cell. At approximately 80 liters (2.8 ft3), GMZ’s TEG was less than one-third of the TARDEC program’s specified size requirement.

With this demonstration, GMZ successfully reached an important milestone in the $1.5 million vehicle efficiency program sponsored by TARDEC and administered by the U.S. Department of Energy (DOE). With battlefield fuel costs ranging from $40 to $800 per gallon, the U.S. military is especially interested in thermoelectric technologies, which are physically robust, have long service lives, and require no maintenance due to their solid-state design.

This file type includes high resolution graphics and schematics when applicable.

GMZ’s patented half-Heusler material is uniquely well suited for military applications. The 1000 W TEG features enhanced mechanical integrity and high-temperature stability thanks to a patented nano-structuring approach. GMZ’s TEG also enables silent generation, muffles engine noise, and reduces thermal structure. Half-Heusler is environmentally friendly, mechanically and thermally robust, although cost may be an eventual issue.

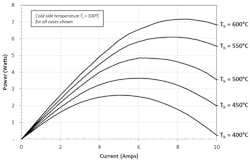

The TARDEC TEG incorporates GMZ’s TG8-1.0 modules (Fig. 2), which are the first commercially available modules capable of delivering power densities greater than one Watt/cm² while operating at 600°C. Fig. 3 shows the power output of a TEG8-1.0 module as a function of current and temperature. The TARDEC 1000W TEG consists of 400 TG8-1.0 modules with associated cold-side and hot-side heat exchangers and manifolds. GMZ did the engineering and CFD simulation to project performance. The technology’s uniqueness is its ability to operate at high temperature gradients (high ∆T), which allows the extraction of more power per unit area of the TEG modules. Fig. 4 shows the TEG module located on a vehicle exhaust manifold.

The next phase of this program will be testing in a Bradley Fighting Vehicle. Besides saving money and adding silent-power functionality for the U.S. Military, this TEG can increase fuel efficiency for most gasoline and diesel engines. This low-cost TEG technology fits into a broad array of commercial markets, including long-haul trucking, heavy equipment, and light automotive.

Due to the high currents involved, GMZ usually employs series connections to maximize voltage and minimize current as much as possible as well as to minimize I2R losses. Because diesel exhaust is less than 600 °C and the module hot side temperature is even lower than the flow temperature, the modules do not give their full power output the way they do in other applications. However, even with the de-rating to account for the lower hot-side temperature, the economics of incorporating these systems is very compelling with payback times typically less than 12- 24 months.

A high ∆T capability can result in higher efficiency in some cases. However, what really matters is the $/Watt. When the input energy is free, the cost of the output energy is driven entirely by the cost of the generator. GMZ designed the system to minimize the $/W in order to maximize their utility to the largest possible set of prospective users. Because any thermoelectric material generates more power with higher ∆T, GMZ focused on half-Heusler material systems, which have very high temperature capability. GMZ modules are rated for 600 °C continuous hot side capability with 700 °C intermittent. This maximizes power per device, which minimizes the $/W. In volume production, GMZ expects its TEG systems to be below $1/W.

GMZ Energy’s proprietary platform technology enables low-cost manufacturing of bulk thermoelectric materials. The company’s nano-structuring process reduces thermal conductivity while maintaining electrical conductivity, enhancing the performance (figure of merit, ZT) by 30-60% across multiple classes of thermoelectric materials, including bismuth telluride, lead telluride, skutterudites, silicon germanium, and half-Heusler materials.

Compared to thin film and nanowire materials, GMZ’s nano-structured bulk materials have superior mechanical integrity and high-temperature (20 °C – 800 °C) thermal stability. GMZ’s TEG materials and processes also allow direct bonding to interconnect without the need for metallization, which lowers costs and increases module durability and life cycle. This enables the module to provide consistent energy over long-term cycling, even in the most challenging environments.