TI Targets Industrial IoT With High-Performance Cortex-R5 MCUs

Texas Instruments is pushing the performance envelope with its new microcontroller family, the Sitara AM2x MCUs, as it works to own more of the hardware powering the industrial Internet of Things (IoT).

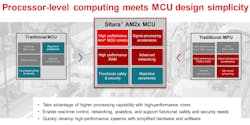

TI said that its real-time, safety-critical microcontrollers close the gap with microprocessors (MPUs) by adding more computing capacity and a larger amount of local RAM memory without compromising on industrial networking and safety. TI said the chips deliver up to 10 times more performance to industrial control modules, motor drives, and factory robots than traditional flash-based MCUs now on the market.

The vendor said the devices are based on Arm's Cortex-R5F CPUs, which carry out the primary processing duties. These are supplemented by hardware accelerators that can speed up signal processing (to support more accurate real-time control), industrial communications (to add faster, more flexible networking to the factory floor), and encryption (to block out hackers and malware), offloading the workloads from the CPUs.

"We are trying to address what we feel is the intermediary gap between what microcontrollers today are able to accomplish and what high-performance processors have been able to address," said Mike Pienovi, general manager of TI’s Sitara microcontrollers business. "We are ultimately bringing all that together in a platform with the ease of development our customers have come to expect from that class of products."

Today, many more computers populate the average factory floor than industrial equipment, ranging from programmable logic controllers, motor drivers, and other modules to the real-time computers inside robots used to hoist heavy objects or place tiny parts on the circuit board of a consumer electronics device. More factories are also loaded with connected sensors that harvest data on temperature, vibration, and other metrics to keep the factory running at peak efficiency and identify problems that can cripple production.

But as software becomes the backbone of industrial automation, TI said its customers demand more real-time processing power than ever to keep these systems coordinated safely and securely. According to TI, available flash-based microcontrollers struggle to process the vast amounts of data traveling around the factory, where every fraction of a second counts. TI hopes to fill the gap in the market with its AM2x line.

Under the Hood of the AM2x

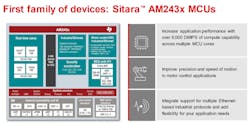

The first family of real-time processors in the AM2x portfolio, the AM243x, pushes TI into the market for industrial-grade high-performance microcontrollers. The chips have up to four Cortex-R5 CPU cores with internal floating-point units (FPUs) clocked at up to 800 MHz combined with a single 400 MHz Cortex-M4F CPU core that can be used to run safety-critical workloads independent from the R5 cores. The chips are based on 16-nm FinFET technology, upgrading from the 28-nm CMOS in TI's AM6x Cortex-A processors.

Every pair of CPUs contain up to 128 kB of tightly coupled memory (TCM), which processors can access directly without having to share a memory bus, reducing latency that can dull a robot's response times.

Along with its microcontroller-grade Cortex-M portfolio of CPU cores, Arm sells its Cortex-R range of “real-time” processors for embedded systems that require high levels of reliability and determinism. The Cortex-R CPU cores, which are also targeting safety-critical workloads in areas including autonomous cars, have protections against various faults that systems are vulnerable to due to the harsh conditions in factories.

The Cortex-R5 cores in the AM243x MCU lineup are only able to run real-time operating systems (RTOS) such as Wind River’s VxWorks and Greenhills’ Integrity, not rich operating systems like Linux or Android.

Unlike standard MCUs, which generally have internal flash memory, the AM2x MCUs feature 2 MB of on-chip RAM so that they can run at peak performance levels and handle richer, more complex software. The chips also incorporate a range of functional safety and security features to reduce the risk of catastrophic failures that can incapacitate factory floors or endanger anyone working around the robot's whirling limbs.

According to TI, with four high-performance Cortex-R5 cores running at 800 MHz, the high-end AM2434 can pump out more than 6,000 million instructions per second (DMIPS) of real-time computing power. TI said flash-based MCUs running at up to 300 MHz can supply less than 1,000 DMIPS. The AM2x family of chips packs all that additional processing power in a power envelope of around 1 W, the company stated.

“Designers increasingly need higher performance at a lower system cost to keep up with the demand for precise control, fast communications and complex analytics," Pienovi said in a recent statement.

That real-time performance is valuable in robots and other factory equipment where faster computations coupled with more on-chip memory can improve the robot's reflexes and control over its movement. That way, the robots can operate without endangering workers and carry out more complex tasks with pinpoint control such as driving screws into enormous aircraft engines or delicately placing parts in a smartphone.

The additional processing power of the AM2x MCUs can also be used to run software that uses sensors measuring temperature or vibrations to prevent wear and tear in the system. Such software could also be used to predict when a machine part may fail, allowing it to be repaired or replaced before it breaks down, preventing a single sudden failure that can slow or shut down sprawling production lines—at a huge cost.

The AM2x microcontrollers have echoes of NXP's i.MX RT family of so-called crossover processors, which incorporate RAM instead of flash memory. In 2019, NXP rolled out its flagship i.MX RT1170, which paired a high-performance Cortex-M7 CPU, clocked at up to 1 GHz, with a 400 MHz Cortex-M4 CPU, which focuses more on power efficiency and operates in a completely independent domain from the Cortex-M7. The chip, based on 28-nm FD-SOI, contains 2 MB of RAM and dual 1 Gb/s Ethernet ports that support TSN and AVB.

Dedicated Hardware Accelerators

TI said customers can wring more performance out of the chip with its wide range of dedicated onboard accelerators and advanced networking that is generally the province of modern microprocessors.

The chips have a dedicated hardware accelerator for industrial communication, including Gigabit Ethernet and time-sensitive networking (TSN) protocols to simplify the increasingly vast wired networks on factory floors. The accelerator can handle a wide range of network protocols from PROFINET, IO-Link Master, and SERCOS to Ethernet/IP and EtherCAT, to meet evolving standards for industrial communications. TI said that as sensors harvest more data from the factory floor, moving all the data around efficiently is critical.

Network acceleration is one of the key features of the AM243x family of microcontrollers. But the chips also incorporate dual Ethernet ports configurable for 10 Mb/s, 100 Mb/s, or 1 Gb/s, the company said.

A secondary hardware accelerator can be programmed to handle higher-bandwidth industrial networking or speed up motor-control software. The accelerator blocks—what TI calls its industrial communications subsystem (ICSS)—have 3x RISC codes for general-purpose, real-time, and transmit functions. Also inside are two 64-bit industrial Ethernet peripherals that can handle time-stamping and other timing functions.

Offloading the networking chores to the hardware accelerator reduces the overhead on the Cortex-R CPUs that are preoccupied with real-time control functions, reducing latency that can disrupt factory equipment. TI said that the hardware accelerators in these chips offload some of the high-bandwidth, compute-heavy workloads such as predictive maintenance to reduce the power draw as well as the total cost of a system.

The company also loaded the AM243x with special-purpose analog and control peripherals such as high-resolution pulse-width modulators (PWMs) and analog-to-digital converters (ADCs) to reduce latency and, as a result, improve response times. The general-purpose peripherals and I/O include 6x I2C, 7x MCSPI, 9x UARTs, and 3x GPIO modules for up to 198 GPIOs, ideal for suctioning data from a wide range of sensors.

Upgrading to Industrial Grade

TI is also bringing more functional safety features into the fold, giving the real-time embedded systems in factories and other areas the ability to safely detect, diagnose, and then work through any faults or errors, preventing harm to other gear or workers on the floor. The AM243x family of devices integrates functional safety mechanisms, diagnostics, and collateral to run Safety Integrity Level 3 (SIL 3) and ASIL-D systems.

The 400 MHz Cortex-M4 CPU serves as a functional safety module, with independent memory (256 kB of RAM), interfaces (a UART and GPIO), and other resources that can run completely isolated from the real-time Cortex-R cores, the vendor said. According to TI, the Cortex-M plays the role of the watchdog in the system with the ability to safely reset the rest of the microcontroller in the event of a malfunction or fault.

According to TI, the new chips have been hardened to be industrial-grade. They are able to withstand the shocks and harsh vibrations that factory gear is subjected to and maintain a wide temperature range of -40°C to 105°C. The AM243x family of microcontrollers is packaged in a power envelope of around 1 W, which allows them to tolerate hot conditions without the use of bulky cooling fans or costly heat sinks.

As more of the factory floor becomes dominated by software, the AM243x family of microcontrollers is targeted to address another possible danger: hacking. The chips have a hardware accelerator that can run up to 256-bit AES, up to 512-bit SHA2, up to 168-bit 3DES, and other types of cryptography, including public key accelerator (PKA) to assist with RSA encryption, protecting the data traveling over industrial networks.

TI said the chips are buttressed with a secure boot. Secure storage of public keys is supported as well.

The AM2x line encompasses three subfamilies—the AM2431, AM2432, and AM2434—giving customers the ability to scale up performance and other features depending on the requirements of the end system, said Sonia Ghelani, business manager of TI's Sitara microcontrollers, in a briefing last week. She said that "customers can dial in the exact version of the AM243x device that works for their specific applications."

The vendor said that it would roll out a wide range of development tools, production-ready software, and reference designs to make it easier to evaluate the AM243x MCUs and build industrial equipment around them. Customers can use TI's ecosystem of software and tools to start taking advantage of the out-of-the-box industrial communications, real-time control, and security capabilities in the AM243x family of MCUs.

Preproduction models of the AM2431, AM2432, and AM2434 are currenting available in 17.2- × 17.2-mm FCBGA or 11- × 11-mm flip-chip chip-scale (FC/CSP) packages. Prices start at $6.05 in 1,000-unit orders.