Special Report: Electrical safety test vendors packing value-adds into solutions

As various applications see demands rise for power usage, power density, and efficiency, the need to test for electrical safety goes hand-in-hand. Software continues to play a growing role in helping automate these tests, while vendors of instrumentation in this field are challenged to keep up current industry standards, and design with future standards in mind. Hipot, insulation-resistance (IR), ground-resistance, and ground-bond (GB) testing are all critical elements of measuring electrical safety across various industries. Thankfully, technology has enabled electrical product safety test instruments user-friendly—increasingly leaving it up to the user’s interpretation or “gut” feeling. Guess-work is an enemy of product safety testing, after all.

Clark added that while these digital features continue to expand in electrical safety test instrumentation, one doesn’t have to buy a large, expensive system to take advantage of these user-friendly capabilities. For example, Vitrek’s V7X series of compact, benchtop safety testers are built around touchscreen technology, with four of the company’s six models priced at under $2,000.

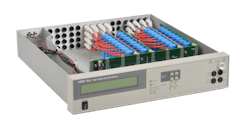

Vitrek has plenty more options to back that up. The Poway, CA-based company offers 14 different models of electrical safety testers to handle a wide variety of testing applications. The aforementioned V7X series consists of six models with AC/DC hipot and IR testing up to 5KV and GB testing up to 30 amps. The V7x series meets the safety test requirements for the vast majority of the of product categories, including most appliances, power supplies, and electrical components. For more demanding application requiring more output power, higher measurement resolution, greater GB test current and hipot voltages up to 30KV, Vitrek’s 95X series of electrical safety compliance analyzers provides an ideal solution.

Trends & challenges

We at EE gathered commentary from a handful of vendors regarding what they see as current trends in the area of electrical product safety testing, as well as ongoing challenges. Here’s what they had to say.

Dan Carter, EST/LCR product manager at Chroma Systems Solutions: “We are seeing more and more demand for traceability in the form of different communication interfaces and the use of data recording software. Many customers are looking for ways to centrally store test data in companywide databases. Our instrument control software packages allow for integration into SQL databases. Vendor challenges: Every customer’s requirements vary and it’s important to cover all bases when specifying equipment for these varying requirements. It can often be difficult to get all of the necessary information from customers in order to correctly identify the perfect piece of equipment for the job. Customer challenges: Standards change and are often interpreted in different ways. This can lead to confusion when trying to be compliant.”

Katherine Homan, president of Cortek Test Solutions: “Standards change and are interpreted differently by both vendors and customers.”

Compliance

Essentially every electronic device or piece of equipment must undergo rigorous electrical safety testing and pass certification before it can be marketed, and the requirements for certification are largely dependent upon many safety standards—which vary by global region. The most prominent organizations setting these standards include: EN/IEC (Europe); UL (US); JEIDA/MITI (Japan); CCC (China); and CSA (Canada).

Some standards between these agencies conflict with each other, and things can quickly become confusing when a vendor from one region sells to a client from another. But, as Vitrek’s Clark noted in a whitepaper he authored for his company published this past November, there is an ongoing effort between these agencies to harmonize standards.[1]

“For example, the IEC 61800-5-1 is a safety standard specified by the International Electrotechnical Commission for adjustable-speed electrical power drive systems,” Clark said in the whitepaper. “It covers the safety aspects related to electrical, thermal, and energy. The former UL standard (UL508C) has now been supplanted by new standard, harmonized with the IEC requirements.”

The UL document announcing the IEC 61800-5-1 change stated, “This harmonization work was undertaken with the intent of creating a standard that, while being based upon and adopting IEC requirements, would incorporate national differences that would address US installation requirements (NFPA 70, US National Electrical Code). This goal has largely been accomplished in all cases.”

On a more local scale, vendors themselves are helping play a large role in helping electrical device manufacturers remain aware and meet safety standards. It’s a service area these vendors can use as a value-add beyond their product offering, and to set themselves apart in the market.

“Vitrek’s application engineering team has years of experience and has assisted thousands of engineers in solving difficult electrical safety compliance test requirements,” Clark said. “We are experts at understanding test specifications and implementing the appropriate automated solution. Often, nationally recognized testing laboratories require that operators perform a daily external verification check to ensure that a safety tester is functioning properly. Vitrek’s application team can provide standard operating procedures for performing these checks with either an off-the-shelf performance verification device (PVD) or design a custom PVD designed around the specification that the user is testing to.”

Chroma’s Carter added that his company helps customers achieve compliance by reviewing their requirements with them and providing solutions based on a combination of their standards-based requirements and wish-list items based on their unique situation.

Now on the market

Vendors of electrical product safety testing will show off their latest and greatest innovations at upcoming industry events such as the Dixie Crow Symposium (March 24-27 in Warner Robins, GA), the Del Mar Electronics & Manufacturing Show (May 1-2 in San Diego, CA), the Medical Device Innovation Program (May 7-8 in Boston, MA), and the Battery Show (September 10-12 in Novi, MI). Let’s take a look at some of what will be showcased there, or in general as new offerings:- Insulation testers—MY600 Digital Insulation Tester; 2406E Series Analog Insulation Tester, which covers 10 voltage and resistance test ranges

- Clamp-on testers—CL Series Clamp-On Testers that span AC/DC/True RMS current and voltage measurement capabilities

- 3003 Series Leakage Testers

- EY200 Earth Ground Tester

Product application options

Besides providing testing instruments, vendors are increasingly adding new options that are particularly applicable for electrical safety test, such as software or probing solutions. Here are some examples.

Homan, Cortek: “In addition to the enclosure itself, options available from Cortek are safety light trees, start/stop switch, E-stop, insulation mats, and specialty materials such as red UV acrylic to temper any bright lights during the safety test.”

Mukerji, Yokogawa: “Our MY600 comes with a line probe that allows the user to disconnect the UUT from the insulation tester at-will; automatic PI/DAR calculations; pass/fail color Indicators for comparative testing; software to stream data collected from the unit to a PC via USB; and a fast response time of 0.5 seconds.”

Operator safety

While the aim of electrical product safety testing is to evaluate the safety of the product itself, the equipment doing the testing must also ensure the safety of its operator—particularly when performing high-voltage tests. What features do vendors offer that aid user safety?Carter, Chroma: “All of our electrical safety testing equipment comes standard with a safety interlock. Our hipot testers also have a GFI feature that will shut down the output in the case that there is current escaping to ground during a test. We can also provide custom fixtures and enclosures that can help create a safe test environment.”

Mukerji, Yokogawa: “Features of our MY600 include a backlight LED that automatically illuminates in dark surroundings; a line probe with an adjustable switch to disconnect the measurement circuit from the UUT; an intermittent buzzer that warns of the high voltage output range; and a ground fault indicator and buzzer once the earth-ground voltage exceeds 30V.”