Electronic devices are all around us, and each industry has their own variety. Healthcare technology, electric vehicles, smart phones, computing, industrial applications, and consumer electronics are all made possible by an immense global electronics design and manufacturing value chain. This value chain is constantly under pressure to improve efficiencies, cut costs, increase margins and compete with new entrants and market demands.

Decisions made during the design stages of product development and testing have a significant downstream impact on overall product performance and profitability. Engineering simulation is a critical tool in the design stage and the cloud has enabled opportunities to optimize and streamline an otherwise complex and costly design process.

Why Simulate?

An electronic device is complex. Capturing the details of its operation and performance needs a physics-based software solution to calculate all the thermal, electronic, physical, and other phenomena the device is subject to. The more accurately we can simulate its performance in a software tool, the more accurately we can predict its performance against simulated scenarios. This means we can reasonably predict how it will perform in the real world with a high degree of confidence.

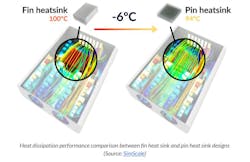

Creating this ‘digital real world environment’ means we can make choices and decisions in the design stage and feel comfortable that they will perform as we expect once we have manufactured the product. For example, in the image a high-density electronics enclosure is simulated in order to compare the cooling performance of a fin type heat sink and a pin type heat sink. This is just one example of a parameter in the overall CPU design which can be simulated. The temperature of the CPU, cooled by the pin type heat sink is 6°C cooler than the fin type heat sink.

Essentially, this ‘digital real world environment’ has replaced costly physical prototyping and testing, which was the norm before simulation tools had matured to a stage where the results were deemed accurate enough. With an optimized simulation software, an electronics design team can work through dozens of different design scenarios without even making a prototype. With integrated optimization algorithms used to automate the design process using machine learning (ML) apps, this scales to hundreds if not thousands of scenarios being modelled and simulated in real time.

The amount of computing power needed for this task is not trivial. HPC capabilities are needed which are easy to access, fast to run, simple to manage and readily accessible. This capability on any significant scale can only be performed on cloud-hosted solutions. Cloud-based applications, as an umbrella term, can be broadly split into two categories; cloud-native and cloud-enabled.

Going Native

Cloud-native applications are innately adaptable and scalable, as modifications can be identified, made, and released to individual modules within the cloud environment in real-time without interrupting the processes of the entire operation/application. This applies to everything from debugging a problem to rolling out new features and regular maintenance and updates. Cloud-native applications require no large hardware or software investments, as opposed to on-premises solutions, and are generally available via a license/subscription plan that can be activated in minutes.

Adding additional users is typically inexpensive, software updates and the maintenance fees are also avoided, and therefore, cloud-native applications tend to be more cost-effective and adaptable. A new module or type of analysis can be easily deployed without needing to re-install software. With an application programming interface (API), electronics designers can now connect simulation software to their preferred geometry and analysis tools directly, making it even easier to implement a high-performing design workflow.

Optimizing a complex electronics design value chain with powerful multi-physics capabilities on the cloud is a powerful combination. For example, consider an electronic device such as a central processing unit (CPU) on any laptop or tablet. A CPU has hundreds of electronic and non-electronic components packed densely into a small encapsulated space with little room in between components. Relatively high voltages and currents are used to operate the device and complicated power management algorithms regulate the flow of power and hence heat dissipation.

A finely balanced heat dissipation strategy is needed using heat sinks, fans, air paths and controls to manage the optimum conditions for best performance. Any diversion from this control leads to overheating and potentially component and system failure. CPUs power the digital world. Any failure can lead to significant economic and physical consequences. In the design of a CPU there must be hundreds of ways to potentially lay out the components. Which one is best? Which one gives the best cost to performance ratio and which one has long term durability and reliability.

Looking forward

‘If you can’t simulate it, don’t build it.’

A designer can import a CPU model into the computational fluid dynamics software and perform airflow, thermal and stress analysis on the component and the CPU system. As the software is cloud-based, it also empowers teams to collaborate. A designer might be collaborating with a manufacturer thousands of miles away or with colleagues in other locations.

The cloud allows for fast and accurate simulations of multiple design scenarios in parallel, saving time and cost. More importantly, the designer can see highly validated and accurate performance of their designs and how it would perform under real world conditions. Before the designers even begin to order components and assemble prototypes, they have converged on a much smaller number of final design variants.