This article is part of the TechXchange: PCB Tools and Technology.

What you’ll learn:

- The complexities associated with the use of solders in electronic products.

- What’s the alternative to solder?

A long-standing adage observes that “if the only tool in your tool chest is a hammer, the tendency is to treat everything like a nail.” Such has been the case for electronics assembly for the last several decades with respect to solder assembly of components to PCBs.

To be fair, the soldering process has been a reliable, even indispensable, workhorse in the electronics industry over those decades. Unfortunately, the forced implementation of lead-free solder, which was foisted upon the electronics industry by the European Union in 2006, had a global effect, altering forever what was a relatively manageable process using tin-lead solder. The electronics industry has struggled and continues to struggle daily to meet the challenge of the lead-free solder mandate.

However, truth be told, even tin-lead solder would be challenged by the current and near-term requirements associated with the dawning of this new era of heterogeneous integration. For their own edification, the reader is invited to look at virtually any journal or newsletter on electronics manufacturing and therein you’ll find article after article and advertisement after advertisement on how to address problem after problem. Nearly all of them are related to the process of electronic component soldering and subsequent, inspection, testing, rework, and repair.

The Problems with Lead-Free Solder

The simple fact is that managing the electronics assembly process using solder technology, especially since the introduction of lead-free solder, has become increasingly complex. Lead-free soldering has unfortunately, introduced to the industry a litany of new types of defects and a number of new failure mechanisms (exclusive of the reintroduction of failure mechanisms that at one time had been fully put to rest, such as tin whiskers, which is easily mitigated by the presence of lead in the solder alloy).

Among the new types of solder-related defects are the following: solder balling, graping, champagne voids, head-on-pillow defects, and poor wetting, to name but a few. While the defects mentioned are primarily related to the formation of a solder joint, a host of other types of defects have arisen, artifacts of the higher-temperature soldering required for traditional tin-silver-copper (SAC) alloys that dominate.

Even as increasing numbers of alloys are put forth (more than 60 presently) as candidates to put the problem to bed, no clearly definable winners are yet visible on the horizon. The list of defects related to high-temperature lead-free soldering include blistering of IC packages, excessive warpage of components that impact solder joint formation, pad cratering, pad cracking, delamination of circuit boards, and many others.

Post-assembly processing is no less affected. A major daily challenge is the thorough cleaning of baked-on fluxes left beneath components. Unfortunately, with ever-finer pitch terminations, reduced standoff heights, and increasing size all being introduced, it’s unbelievably daunting but necessary to remove that residue to give the assembly a fighting chance at not evidencing ionic contamination failures at some point in time in the future.

Clearly, soldering, as faithful an industry servant as it has been over the years, has now become a technology that’s as much a liability today as it has been a benefit to electronic manufacturers in the past. Given the challenge, one question could or should be rightfully asked: “Is soldering really the only possible solution for making connections for an electronics assembly?” The short answer is “No.”

Rethinking Electronics Assembly

An alternative method called the Occam Process was conceived in response to the introduction of lead-free. It’s remained poised and ready to enter the arena as a way to make electronics that are expected to be superior to the current process from perspectives such as cost, performance, reliability with reduction in size and weight, and improved thermal and electrical interference management.

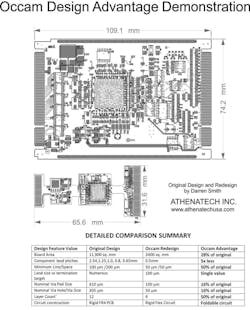

To illustrate, Figure 1 provides a comparison between traditional and the Occam approach to clearly illustrate the potential.

Basic Occam Process Description

Assuming the illustrated advantages have appealed to the reader, the logical question for those unfamiliar is likely “Is that really possible?” The answer is “yes,” and it can be done completely without solder.

In a nutshell, the Occam Process is designed to reduce complexity and minimize process steps by basically reversing the manufacturing process. Specifically, rather than putting components on circuit boards and soldering them to the PCB, a “component board” is first assembled and circuits are built up on these boards. The benefits shown are all derived from this simplified approach.

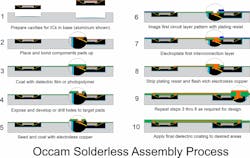

It’s been said often over the decades that a picture is worth a thousand words. With that timeless advice and wisdom in mind, Figure 2 shows the process steps involved.

Obvious questions that many seasoned assembly engineers would likely ask is “What about rework and repair?” or “What about testing?” In keeping with William of Occam’s centuries-old admonishment “It is vanity to do with more that which can be done with less” and 20th century quality guru W. Edwards Deming’s advice “Test 100% or nothing,” testing in process was seen as an unnecessary and wasteful step.

However, pretesting is required for the components, as starting with bad components is a “fool’s errand.” The fundamental principle to be applied is to “first do the right things and then do those things right!”

Given the greater simplicity of the Occam Process, there should be more than enough time to do those things right given the many fewer steps. Testing it is arguably the equivalent of training wheels on a bicycle—they may help the novice rider stay upright, but they impede turning and slow the rider down. Obviously, there will be those who will suggest the thought is pure heresy. But if one thinks critically about the value of test, it provides little to none beyond weeding out assemblies that failed because of the inherent weakness of the soldering process.

Summary

Solder, while it has certain unquestionable advantages, also has an ever-growing list of liabilities. This is evidenced daily in electronic manufacturing facilities globally by the myriad rework stations whose sole purpose is to correct defects resulting from a process that is, and likely always will be, inherently weak.

The Occam Process proposes a significant reduction in materials and processes. Oddly, it’s an observable fact that it’s much easier to make things more complex than to make them simpler, just as addition is easier to learn than subtraction.

Unfortunately, it’s also an observable fact that manufacturing generally abhors change in much the same way nature abhors a vacuum. It’s a function of the reality that humans are no less subject to Newton’s laws of motion than the physical universe especially in the case of inertia… things in motion tend to stay in motion, traveling in the same direction unless acted upon by an external force.

Solder is an incumbent technology with a long history of its own. And despite the abusive challenges thrust upon the industry by the lead-free mandate, solder continues to be used and that will go on for many years to come.

However, after many years, what’s finding some appeal among some of the more enlightened technologists in the industry is that reliable solder-free solutions are possible and achievable today by simply “stepping through the looking glass” of perception and following the advice of Steve Jobs to “think different.” Thinking different and perhaps picking up a tool other than “just a hammer” might be, upon reflecting on the thoughts contained in this brief article, might have some appeal among readers who grasp the concepts and are not afraid of change—one of the only certainties in life.

Joseph Fjelstad is the CTO of The Occam Group.

Read more articles in the TechXchange: PCB Tools and Technology.