New NVM Technology Intended to Replace Flash Memory

Check out the other 2023 IDEA Award Nominees.

Weebit Nano recently introduced Weebit Resistive RAM (ReRAM), a non-volatile memory (NVM) that eventually replaces flash memory. It has higher performance and better security, costs less, and consumes less power than flash or other NVMs, suiting it for companies designing systems-on-chip (SoCs).

The company integrated its ReRAM IP in the SkyWater 130-nm CMOS process (S130). This radiation- and electromagnetic-interference-tolerant and high-speed NVM targets SoCs in IoT, automotive, analog/mixed-signal, industrial, data-logging, medical, aerospace and defense, and other applications.

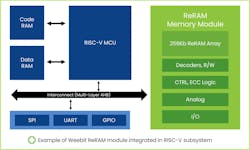

The ReRAM IP is an embedded module containing a set of collateral and electronic-design-automation (EDA) views for easy integration via advanced EDA tools. The S130’s module features control logic, input/output communication elements, error-correcting code, decoders, and a 256-kb ReRAM array (customizable for 128 kb to 2 Mb).

Thanks to the modular and scalable design, it can be customized based on requirements, such as system interface, word size, memory density, etc. In addition, this module has special patent-pending analog and digital circuity running smart algorithms to boost the memory array’s technical parameters. It even comes with a quick boot-up thanks to the fast access time, and the secure technology is embedded between two metal layers.

Users can have the module as part of a subsystem like a RISC-V microcontroller, static random-access memory (SRAM), system interfaces, and peripherals. Plus, the Weebit ReRAM is scalable based on various processes. SkyWater S130 has an APB system interface that can also be customized to AXI/AHB/QSPI/OBI.

The 130-nm node is a “dual-gate technology with 1.8- and 3.3/5.0-V devices.” It supports a maximum of five aluminum metal layers and is mixed-signal-enabled with native, NPN and PNP BJTs, MIMs, inductors, extended drain, etc. Customers can optimize it for performance and power via the provided thresholds.

Overall, the Weebit ReRAM IP is qualified for 3X SMT solder-reflow cycles, 10k to 100k write cycles, 10 years of data retention at 85°C (can reach 125°C), and retention after cycling, achieving robust lifetime performance.