This file type includes high-resolution graphics and schematics when applicable.

Today’s homes and workplaces are increasingly pervaded by smart appliances, which are designed to be attractive and reliable, and ideally should support interactions that are as easy and rewarding as those delivered by the smartphone sitting in the user’s pocket.

As new smart appliances like televisions, set-top boxes, audio equipment, white goods, PC peripherals, security panels, and industrial controls enter the market, the design of the user interface and the quality of the user experience delivered have a critical influence on market appeal and, ultimately, sales and revenue. Creating a good impression through the user interface is vital, and designers can choose from a range of technologies, such as conventional pushbutton switches or various types of touch sensors.

Switch or Touch—Pros and Cons

Mechanical switches like membrane or tactile switches are a mature technology that offers advantages including low cost, easy availability, and straightforward integration requiring minimal electronic design or software engineering. These types of switches also provide reassurance for the user by giving tactile feedback to confirm that the button-press has been detected. On the other hand, some disadvantages of mechanical switches include relatively slow response times, poor reliability owing to reliance on moving parts, and the possibility that additional noise-suppression or de-bounce circuitry may be required.

On the other hand, a touch sensor can create a more modern impression, and it simplifies construction and assembly. It does away with the panel cut-outs typically needed for installing mechanical switches, and helps simplify the mechanical design of the control panel. The panel also can be sealed more easily against ingress of liquids, such as water. This is a valuable feature for many types of equipment, such as kitchen appliances like coffee machines, and simultaneously enhances reliability as well as facilitating cleaning.

Among touch-sensing technologies in use today, which include capacitive, resistive, or piezoelectric sensing, capacitive sensing is widely used among products in the market today. Capacitive touch sensors can be deposited easily on glass or plastic using a process such as screen printing, making it possible to create a variety of shapes such as buttons, sliders, or rotary selectors. Backlighting is also easy to arrange.

In the absence of any mechanical response confirming actuation, as provided by a tactile switch, the designer may use light to confirm detection of touch. This can be exploited to create stylish effects, such as keeping the panel dark until touched and using color-change effects or high-tech icons. Discreet audible beeps or jingles may also be introduced to complement the touch controls. All of these effects are in keeping with the sophisticated look and feel enabled by a touch-sensitive user interface.

Sensing Principles

Generically, capacitive sensing operates by detecting a change in the basic capacitance of the sensor pad upon the approach of the user’s fingertip. In the self-sensing type of detector, the approaching finger effectively adds to the sensor’s capacitance. The change increases the time constant of the touch-pad circuit, which is detected by charge-time measurement circuitry implemented in the touch-sensor controller.

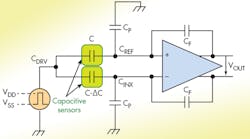

An alternative technique is mutual differential sensing. It detects a reduction in the capacitance formed between the sensor pad and a separate excitation pad as the user’s fingertip comes into proximity with the touch panel. The change in capacitance (ΔC) is detected and converted into a voltage (VOUT). Figure 1 illustrates a differential-amplifier circuit used to generate VOUT. This has a linear relationship with ΔC, and is compared with a threshold voltage (VT). Touch detection is indicated when VOUT exceeds VT.

Mutual differential sensing delivers an advantage through improved sensitivity for a large dynamic range. The practical benefits of this include extended flexibility in terms of sensor-pattern design, and tolerance of long sensor trace lengths due to superior cancellation of parasitic capacitances (CP) between pad and ground. In practice, trace lengths up to 500 mm have been demonstrated successfully.

Touch-Controller Implementation

The touch sensor must have an electronic controller with enough channels to support the required number of touch buttons. Historically, the controller has been implemented either as a standalone application-specific IC, or integrated in a microcontroller. A microcontroller-based solution may use a combination of analog peripherals and software, while others provide dedicated on-chip touch-control functionality such as a charge-time measurement unit (CTMU) for use with self-sensing detectors. The microcontroller vendor may provide free capacitive-touch software IP, which can help simplify code development.

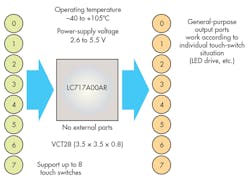

Implementing a standalone controller brings a number of advantages. An IC such as ON Semiconductor’s LC717A00 doesn’t require a host microcontroller, and has several built-in features including noise cancellation and water detection, to prevent spurious responses. In addition, patented automated noise and environmental-change compensation technology is also built in to prevent noise-related malfunctions and compensate effects that can alter sensitivity, such as changes in humidity or accumulation of dirt on the sensor area.

The controller’s internal circuitry features a unique C/V-conversion amplifier, which converts the monitored differential capacitance to an output voltage. No need for programming helps shorten development time, and because no additional external components are required, it minimizes bill-of-materials costs.

Figure 2 shows the LC717A00 used in standalone mode for controlling up to eight capacitive touch sensors. The device features a communication port, either I2C or SPI, allowing for convenient connection to a host microcontroller if required.

The controller uses the differential signaling method, which delivers high sensitivity and extends freedom for designers to create control panels in a wide variety of shapes with long connection lengths. Figure 3 shows a sample touch-panel design with extremely long trace lengths. The data rate is configurable to over 200 Hz, thus enabling its use in equipment that requires rapid touch response.

The controller’s high signal-to-noise ratio (SNR) increases touch-sensing reliability, even while wearing gloves. Oftentimes, this isn’t possible with self-sensing type detectors. Moreover, the design rules governing the shape and size of senor electrodes, and the effects of air gaps as well as overlay thickness and material, can be relaxed.

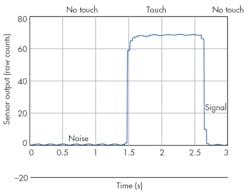

Figure 4 shows an example of signal and noise levels using real sensor data. In this example, the signal is a 17,000-count difference and the noise is a 160-count difference; therefore, the SNR is 106:1.

Conclusion

Capacitive touch has many strengths as a user-interface technology for modern smart appliances. Mutual differential sensing ensures reliable touch detection and allows for greater design freedom when laying out the control panel and selecting materials. A standalone application-specific touch-control IC supports convenient and fast implementation, based on this mutual-differential-sensing technique, and can deliver advantages such as elimination of software design, saving on external components, and acceleration toward project completion.

Looking for parts? Go to SourceESB.

This file type includes high-resolution graphics and schematics when applicable.