A Sensor-Fusion Approach to First Responder Precision Location/Tracking

This file type includes high-resolution graphics and schematics when applicable.

Locating first responders deep within GPS-denied infrastructure with high precision has been an elusive goal of the fire safety and emergency personnel community for well over a decade. The objective is to pinpoint location to within a few meters, over the course of tens of minutes. These coincidentally are nearly the same goals for guidance systems on tactical missiles, and the preferred solutions today for such systems can cost $10K minimum, in addition to having prohibitive size/weight/power. Those same solutions were used in early proof-of-concept demonstrators for first responders, but proved to be barriers (cost and size) to actual deployment.

First responder location determination therefore remains one of the most complex location applications in existence today. No one silver-bullet sensor can achieve the desired goals—instead, multiple technology nodes are necessary, each being at the leading edge of capability. Further, it involves a large-scale sensor-fusion and system-integration approach.

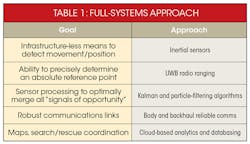

Cost-effective high-performance MEMS inertial sensors can now provide the seed for a potential solution. This article envisions a complete sensor-to-cloud sensor-fused system including highly sophisticated algorithms. The major approaches and enabling technologies are described in Table 1.

The major challenges facing system developers can be summarized into three broad categories: procedural, environmental, and sensor fusion. The highly complex nature of the first-responder mission, coupled with the challenges posed by the varied and extreme environment, must be comprehended without compromise in the course of designing a multi-sensor solution.

Procedural

The fire safety search and rescue mission follows a highly disciplined process, which at the same time must adapt to fully non-deterministic real-life scenarios. A deployable precision location system must adapt to existing processes and equipment, to the greatest extent possible.

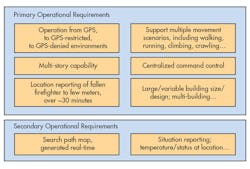

Thus, one requirement is to be operational without any fixed or ad hoc infrastructure. Because first responders are typically burdened with significant equipment (weight and cost) already, any system development should be guided from the early stages by the goals of achieving miniaturized embedded equipment, and per responder costs on the order of a smartphone (it’s useful to point out here that existing smartphone location performance is highly inadequate; thus the challenge). Fig. 1 outlines the most relevant primary and secondary operational requirements of the desired system.

Environmental

While outdoor positioning has become ubiquitous with GPS coverage, a fully indoor or mixed (indoor/challenged-outdoor) environment is far less supported. Some indoor positioning situations (e.g., shopping mall) can be realized with installed infrastructure. However, these are neither precision, nor practical, for the first responder goal. For the system designer of a tracking system, the following considerations drive design definition, component choices, and risk-mitigation approaches:

• RF propagation paths

• Temperature/shock effects on sensors

• Potential for damaged/altered infrastructure

Sensor Fusion

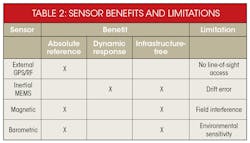

The challenges noted above in process and environment form the basis of the central design approach to this problem: sensor fusion. Relevant primary sensing modes are selected to provide uncompromised performance in critical operational modes, while at the same time complementary sensors are matched to the key obstacles for each phase of the application (Table 2).

Due to the ability of microelectromechanical systems (MEMS) to operate free of external infrastructure, and provide precision in a dynamic environment, they’re expected to play a primary role in the overall solution. That is, of course, if they can operate in extreme environments, and are coupled with the appropriate secondary sensors.

Progress in MEMS

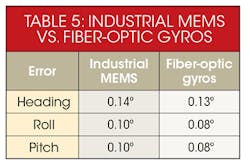

While consumer inertial MEMS devices race toward commoditization (with limited focus on performance specifications), and military MEMs remain prohibitively expensive, industrial and automotive MEMS (Fig. 2) are aiming for an enabling level of both performance and cost.

The industrial and automotive sectors require accurate sensing in relatively complex and extreme environments, compared to the consumer sector. As a result, suppliers to this sector have incorporated architectural features that are specifically tuned to reject performance detractors such as off-axis motion, vibration and shock events, and errors induced from time and temperature.

Though such design features are often most easily accommodated via larger sensors or more costly processes, the economic pressures of both automotive and an increasingly important industrial market force a more critical approach to designing for performance and cost-effectiveness. The result is a highly attractive performance/price positioning for MEMS components specifically developed for industrial applications.

To understand this advantage, one must look deeper into the critical specifications of a MEMS component relative to the targeted application. In the case of the first responder goal, one critical task of MEMS sensors is to discern the type of movement being experienced, and then measure the steps and stride.

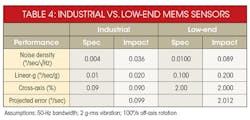

As opposed to a pedestrian motion model, first responder movement will be more random, dynamic, and difficult to discern. Further, because of the accuracy goals, the sensor must be able to reject “false” motion such as vibration, shock, and side-to-side rock/sway of the foot or body. Rather than a simple accuracy analysis based around the noise of the sensor, which may be sufficient for a pedestrian model, the first responder model must also include key specifications such as linear-g rejection and cross-axis sensitivity.

Table 4 provides a side-by-side comparison of an industrial and low-end MEMS device, looking at the RSS error combination of three notable specifications. It can be readily seen that noise isn’t the determinant factor. Rather, the overriding concerns are linear-g and cross-axis performance, which many low-end devices don’t even specify.

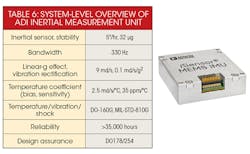

An example of an industrial MEMS inertial measurement unit (IMU) is Analog Devices' ADIS16488A (Fig. 2, again), which incorporates 10 degree-of-freedom high-performance sensing. It has been qualified for commercial avionics (Table 6), demonstrating its readiness for the extreme demands of first responder applications.

Advances in inertial MEMS performance, with continued proof of quality and ruggedness, are now being combined with significant strides in Integration. This last hurdle is particularly challenging, as sensor size can be inversely proportional to both performance and ruggedness if not carefully managed otherwise. A highly strategic, coordinated, and challenging series of process advances must be proven and merged to enable the level of “performance density” required of this application (Fig. 3).

Sensor Weighting

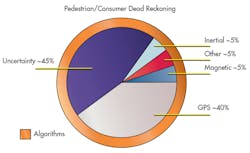

The selection of appropriate sensors for a given application is generally followed by deep analysis to understand their weighting (relevance) during different phases of the overall mission. In the case of “pedestrian dead reckoning,” the solution is dictated primarily by available equipment (i.e., embedded sensors in a smartphone) rather than by designing for performance. As such, there’s a heavy reliance on GPS, with the other available sensors like embedded inertial and magnetic offering only a small percentage contribution to the task of determining useful position information.

This works reasonably well outside, but in a challenged urban environment or indoors, GPS isn’t available. Couple that with the poor quality of other available sensors, and it leaves a large gap or “uncertainty” in the quality of the position information. Advanced filters and algorithms are typically employed to merge these sensors, but without either additional sensors or better-quality sensors, the software does little to actually close the uncertainty gap. Ultimately, it significantly lowers the confidence in the reported position. This is conceptually illustrated in Fig. 4.

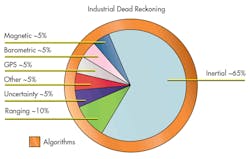

In contrast, the industrial dead-reckoning scenario, such as first responder, is designed for performance, with system definition and component selection guided by specific accuracy requirements. Significantly better-quality inertial sensors allow them to take the primary role, with other sensors carefully leveraged to reduce the uncertainty gap. Algorithms are more focused on optimal weighting/handoff/cross-correlation between the sensors along with an awareness of environment and real-time motion dynamics, rather than extrapolating/estimating position between reliable sensor readings (Fig. 5).

Accuracy in either case above can be enhanced via improved quality sensors. However, while the sensor filtering and algorithms are a critical part of the solution, they don’t alone eliminate the gap in coverage from limited quality sensors.

Precision Location and Mapping (PLM) System

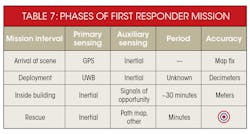

For the specific case of first responder tracking, the mission has been partitioned into the following stages to best assess sensor-processing requirements: arrival at scene; deployment; inside the building; and rescue (Table 7).

It’s envisioned that the fire truck is equipped with a high-end GPS/INS system that’s capable of geo-fixing the position of the vehicle upon arrival at the scene, as a known reference point. From this point, and until the firefighter enters the building, there’s an indeterminate and random sequence of movement. At this stage, the Precision Location and Mapping System relies on an ultrawideband (UWB) ranging implementation to maintain an accurate fix of the firefighter position and orientation. Upon entry into the structure, the inertial sensors become the primary tracking sensor, with the goal of providing location accuracy of a few meters.

The system is designed to solely rely on inertial sensors if need be, but also be able to take advantage of other signals of opportunity when available and reliable, such as UWB ranging signals, magnetometer corrections, and barometric pressure measurements. The implemented algorithms not only track location, but generate a real-time path map of the search pattern. If a firefighter goes down or is in distress, the map generated from the initial path is a supplemental “sensor” input to the rescue firefighter who is also guided by inertial sensing.

While high-performance sensors are certainly at the heart of the PLM system, the following are critical enablers of the system as well:

• Deep understanding of the component sensors and their drift characteristics/limitations under stress

• Extensive knowledge of the human-body movement model

• Detailed application-level insights, and operational-modes definition

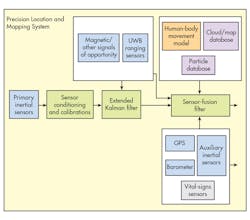

The above provide the definition, guidance, and boundaries for implementing sensor-fusion processing (Fig. 6). The core of the processing is a particle filter that tracks multiple possible movements over time, eliminating errant paths as the filter distinguishes them. The sensors themselves are distributed on the firefighter for optimal performance, and a wireless body network plus rugged backhaul communications network seamlessly connect firefighter, rescuer, and command & control, as well as cloud-based maps and coordination where possible and useful.

The PLM System provides an infrastructure-free approach to detecting position, leveraging high-performance sensors and advanced algorithms to optimally merge all signals of opportunity. The system goals are meter-level accuracy and real-time path-map generation. Advances in industrial-grade MEMS inertial sensors have enabled PLM, and a full systems-development approach makes it possible to address technical hurdles while also achieving commercial metrics.

Continuing work is focused on integrating the latest-generation sensor advances, and matching these to new insights in the first responder operational scenario definition. Final integration will include optimized form factors and body placement, as well as more complete implementation of the required communications links and final system qualifications.