The U.S. Before and After the CHIPS Act

What you'll learn:

- Types of funding/investments generated by the CHIPS Act.

- The latest revenue estimates involving planned U.S.-based chip manufacturing.

- What will these new foundries and facilities mean in terms of job creation?

The U.S. will add more chip manufacturing capacity than any other country in the next decade, which is a direct consequence of the CHIPS Act, according to estimates by the Semiconductor Industry Association (SIA).

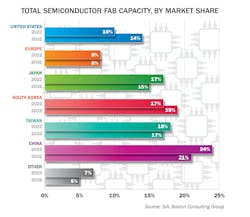

Fueled by funding and other incentives from the CHIPS Act, many of the movers and shakers in the chip industry are investing tens of billions of dollars to build U.S.-based fabs or expand existing ones. As a result, U.S. fab capacity will triple by 2032, as reported in a study prepared by the Boston Consulting Group and commissioned by the SIA, a trade group representing top U.S. chipmakers. In the SIA report, the construction boom is forecast to boost the U.S. share of global fab capacity to 14% in a decade.

This would mark the end of a decades-long decline in U.S.-based fabs, as companies moved investment overseas or halted in-house manufacturing in favor of working with foundries located outside the U.S.

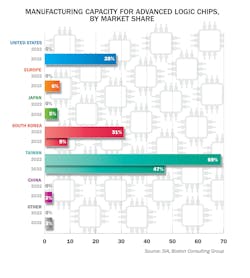

Importantly, the U.S. is also rebuilding its capabilities in advanced chipmaking. The country is projected to produce 28% of the world's most advanced logic chips by 2032, up from 0% in 2022 when the CHIPS Act was enacted.

The U.S. remains a leading player in everything from chip design to electronic design automation (EDA) and fab equipment. But it has undoubtedly been struggling to stay relevant in building chips themselves. The U.S. used to be on top, accounting for about 37% of global fab capacity in 1990. However, it’s fallen behind both in terms of quantity and quality. When Intel lost its leadership in advanced logic chips in recent years, so did the U.S.

In 2020, the U.S. was responsible for only 12% of the world’s production capacity measured in wafer starts per month. That figure fell to 10% in 2022, with estimates showing that share would have slipped to 8% in a decade without subsidies or other incentives to lure investments to U.S. soil. The U.S. passed the CHIPS Act to turn the situation around, while reducing its increasingly risky dependence on foreign chip supplies.

The CHIPS Act: Driving a U.S. Semiconductor Revival

Under the CHIPS Act, the U.S. plans to parcel out $39 billion in subsidies and more than $75 billion in loans to convince semiconductor firms to create, expand, or upgrade fabs on U.S. soil. The legislation is luring investment.

Even before the CHIPS Act was officially enacted, the U.S. had secured commitments from many of the world’s largest semiconductor firms. This includes the three most advanced producers of logic chips: Intel, TSMC, and Samsung.

The U.S. Commerce Department is responsible for doling out the funding from the CHIPS Act. Though not distributing the funds yet, it’s been pledging preliminary grants to companies investing in U.S.-based fabs, including $8.5 billion for Intel, $6.6 billion for TSMC, and $6.4 billion to Samsung. By themselves, the awards account for more than 50% of the manufacturing subsidies under the program. The U.S. has also approved them for loans totaling tens of billions of dollars to assist with construction costs.

The U.S. announced $1.5 billion in grants to GlobalFoundries, the largest American contract chipmaker and trusted foundry for the U.S. Department of Defense. Micron, the largest U.S. supplier of memory chips, was awarded $6.1 billion in funding, too.

The funding from the CHIPS Act is only a fraction of what semiconductor firms are spending on U.S. expansion plans. Since the legislation was proposed, companies in the semiconductor ecosystem have pledged more than 80 new projects on U.S. soil spread over 25 states, totaling close to $450 billion in private investment. Besides the funding, the CHIPS Act also created a 25% tax credit for purchases of semiconductor fab equipment to reduce the inflated cost of building and upgrading fabs in the U.S.

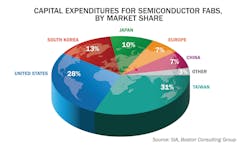

On top of that, the U.S. is expected to amass 28% of global capital expenditures in chips from 2022 to 2032. That would put it in second place behind Taiwan, which will account for 31% of global spending over the same span. Without the CHIPS Act, the U.S. would be losing out on most of these outlays, said the SIA. Given the pace of investment before enactment of the act, the U.S. would have only captured 9% of capital spending.

The result is that U.S. fab capacity is forecast to rise by 203% between 2022 and 2032, according to the report.

“These investments will help America grow its share of global semiconductor production and innovation, furthering economic growth and technological competitiveness,” said Rich Templeton, chairman of the SIA’s board of directors. Templeton is the former CEO of Texas Instruments, which is funneling tens of billions of dollars of investment into its U.S. fabs. TI is also applying for federal aid from the CHIPS Act.

A potential hurdle to U.S. expansion of the semiconductor industry is staffing. Fabs under construction in the U.S. will create more than 56,000 jobs in the coming years, said the SIA, and not enough technical talent is entering the industry to fill all of these jobs. U.S. companies and universities are aiming to tackle the problem before it’s too late.

In addition to allocating more than $10 billion to boost U.S. research and development (R&D), the act also creates funding to train the next generation of chip designers and the technicians to staff all fabs under construction in the U.S.

The Year Before and the Decade After the CHIPS Act

The upcoming U.S. semiconductor boom stands in stark contrast to the 11% increase in fab capacity that occurred from 2011 to 2021. That growth rate ranked last among all major chip-producing regions.

In the U.S., companies plan to expand production capacity across the board, including for AI silicon and other logic chips based on both the latest and legacy nodes as well as DRAM, HBM, and other types of memory chips. The U.S. also aims to boost its output of analog and power chips, sensors, and other legacy components that played a key role in prolonging the global chip shortage sparked by the pandemic.

But most important are U.S. advances in the realm of logic chips. The SIA estimates that the U.S. will increase its domestic output of advanced logic chips—those based on process technologies smaller than 10 nm—from 0% to 28% of the global total by 2032. If the projection pans out, it will put the U.S. right behind Taiwan, which will stay on top of the world in advanced logic-chip capacity at 47%.

The forecast aligns with one of U.S. Commerce Secretary Gina Raimondo’s most ambitious goals for the CHIPS Act: She said the U.S. is aiming to produce 20% of world’s “leading-edge logic chips” as soon as 2030.

The SIA added said that building more manufacturing capacity could also secure the U.S. supply chain against geopolitical shocks and shield the U.S. economy from the types of disruptions that occurred during the pandemic.

Even though it’s expanding output of everything from advanced logic chips to the materials used to build them, the report warns the U.S. still faces vulnerabilities in all of the same segments of the supply chain. The SIA, consequently, said it wants the U.S. to contribute even more funding to the effort.

The CHIPS Act “has put America on course to significantly strengthen domestic semiconductor production and R&D,” noted SIA president and CEO John Neuffer, “but more work is needed to finish the job.”