This file type includes high-resolution graphics and schematics when applicable.

Some have called the Internet of Things (IoT): “A world where the real, digital, and the virtual are converging to create smart environments that make energy, transport, cities and many other areas more intelligent.1” Some projections have 50 billion devices connected to the internet by 2020.2 IoT is not science fiction; it’s not even brand new. Nonetheless, it’s growing at an incredible pace.

With this growth in mind, companies are transitioning strategically to take advantage of this opportunity. General Electric (GE) plans to move from Fairfield, Connecticut to Massachusetts, home of Massachusetts Institute of Technology (MIT). MIT is dedicating resources to IoT, and GE Chairman and CEO, Jeffrey Immelt, speaks to the advantages of moving: “We want to be at the center of an ecosystem that shares our aspirations.3”

Tech titan Nokia is investing heavily in IoT. CEO Rajeev Suri says, “We are launching a $350 million IoT investment fund through Nokia Growth Partners. Our goal is to help accelerate the broad IoT ecosystem, increase the demand for connectivity, and generate returns from investments in compelling opportunities.4”

While these giants of their industries are making significant changes, they’re not alone. This increasingly connected society we live in has given birth to companies with IoT at their core. For instance, recent startup LitBit is trying to make outdated data-center monitoring systems smarter by updating “legacy IoT systems.” The company has raised a total of $10 million in venture capital.5

Many other companies sprang up due to IoT, and more launch each day. These investments are no small decision. GE, Nokia, and startups like LitBit are betting the IoT boom has just begun.

With this rapid advance in IoT and companies ravenously pursuing potential opportunities, it’s important to remember that the key drivers behind IoT are sensors and transmitters. In order to create smarter homes, cities and societies, automation is crucial. Without automation, IoT doesn’t scale.

With a wide range of applications, a multitude of power requirements come into play. Home appliances and industrial automation equipment both traditionally are connected to power lines, making power readily available. Other applications are in locations inconvenient for line power, creating a need for autonomous power sources. These autonomous power sources for sensors and transmitters are often batteries that must be replaced.

Renewable energy offers an economic alternative. Heat, motion, and light can be used to help power the IoT boom by extending battery life or replacing batteries altogether.

Power requirements range widely across applications. An asset tracking application on a semi trailer using a cellular connection to transmit data requires 1 to 5 watt-hours per day. A monitoring sensor that may be calling in status data within an industrial building through Wi-Fi or Bluetooth will require far less power—only a couple of milliwatt-hours per day. Home security systems communicating to a central computer require something between those.

Addressing these varying power needs requires a range of power sources and batteries. While the price of lithium-based batteries continues to fall, extending battery life or eliminating batteries altogether provides clear economic benefits to IoT system integrators, device manufacturers, and users. Three common autonomous power sources include thermoelectric, kinetic, and photovoltaic (PV) systems.

Thermoelectric Devices

When a temperature gradient is available, thermoelectric devices are used as a power source for sensors, e.g., a heat source and a heat sink with ambient air or a cooling fan. The basis of this power conversion is a voltage created between dissimilar materials and current driven with a material by the temperature gradient.

The two dissimilar materials comprising the thermoelectric device are typically positive and negative doped semiconductors, with their junction at the heat source. The opposite side of the semiconductors is at the heat sink. The value of the voltage depends on the specific materials, and the current typically depends on the temperature difference. The semiconductor materials need to have high thermal resistance to keep the temperature difference high. Still, the amount of power is usually near 100 mW for a temperature difference of 50°C and only a few 10s of milliwatts for a difference of 10°C.

Thermoelectric generation works best for sensors in applications such as engines, where a natural temperature gradient is available. Since there are no moving parts, this method can be quite reliable.

Kinetic Power Generation

Kinetic or cyclic mechanical motion, such as vibration of a moving vehicle or a human walking, is also used to generate power for sensors. Most common conversion methods include an electromagnetic device, where a magnet moves back and forth through a coil by the oscillatory motion. The mechanical motion determines available power.

Small power draws, from 10s to 100s of milliwatts, have minimum impact on the mechanical system. However, drawing significant power from human motion takes a substantial amount of energy from the individual and may be counterproductive.

With this method, power is only available with motion. In addition, mechanical motion generally results in wear of multiple components; therefore, lifetime of the device is limited.

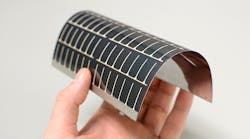

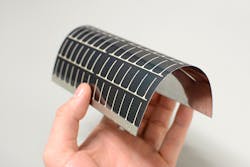

Photovoltaic Power Generation

Light of any intensity or wavelength generates electricity through the appropriate semiconductor PV device. A simple PV device includes a junction of positive and negative doped semiconductors that create a voltage at their junction. The semiconductor that’s absorbing light creates carriers, which in turn provide the current.

The voltage of a device is determined by the properties of the semiconductor. The current will be directly proportional to the light intensity.

Single devices can easily be connected in series to deliver power to meet specific needs. These solid-state devices are exceptionally durable with a long lifespan. They are also very versatile—their only limitation is if light isn’t available for an application. One PV technology in particular—amorphous silicon—can have very low light levels (down to 200 lux), and light is able to be provided by indoor sources rather than outdoor sunlight.

Calculating Power Demand

To accurately size the PV solution, the first step is to calculate power demand. There will be a low-level, standby demand consistently throughout the day, 24/7. There will also be demand spikes during periods when the connection is made and data is transmitted. A typical Bluetooth system may draw small levels of several microwatts in the steady-state standby mode. The typical transmission cycle will demand a higher output for up to a second. If the application transmits data once per minute, this will be 1440 transmissions per day.

To get the power used for the day, one needs to add the standby power to the power draw for those transmissions. To provide a reasonable margin, the PV module should provide an average of twice this requirement per day throughout the year.

Here’s an example:

• Steady-state: 3 µW continuous

• Burst draw: 1.5 mW average over burst

• Burst duration: 1 second

• Burst frequency: 1/minute

• Energy consumption:

- Standby: 24 hours/day × 3 µW = 72 µW hours/day

- Burst: 1.5 mW × 1 sec. × 1/min × 60min/h × 24 hours/day = 600 µW hours/day

- Daily total: 72 µW hours + 600 µW hours = 672 µW hours/day

• The panel needs to provide two times this power, or 1.35 mW hours/day.

• If the panel is in a work area where the lights are on 10 hours per day, then the panel would need to produce about 135 µW at ambient light to supply this load.

• An amorphous-silicon panel manufactured to perform best in low light can provide this in a couple square inches of material at light levels as low as 400 lux.

Why is Amorphous the Best Option for Indoor IoT?

All PV is light-sensitive, but amorphous silicon is the best PV option in indoor IoT applications for several reasons, including the monolithic interconnect and limited leakage patterns.

In small areas, like indoor PV panels for IoT sensors and transmitters, series interconnection helps to maximize power output. Other photovoltaic technologies can work in indoor settings, but they require more engineering and associated expense. Amorphous’ maximum functionality and ease in manufacturing make it ideal for mass production and indoor use.

Leakage patterns are areas in a solar module that allow generated electricity to escape unused. The more leakage paths in a module, the more that module must create to overcome this deficiency. Amorphous silicon has extremely low leakage patterns when compared to other technologies. Therefore, you retain almost all of the power you create, maximizing returns where light is at a premium.

Conclusion

Companies large and small are moving rapidly to capture opportunities in the explosive growth of the IoT ecosystem. Indoor automated power is crucial to help scale IoT for years to come. “Set it and forget it” power is more important now than ever.

Considering the three most common autonomous power sources—thermoelectric , kinetic, and photovoltaic—amorphous silicon becomes the clear choice for powering sensors, transmitters, and other vital parts of IoT solutions, especially indoor solutions. Due to inherent design characteristics, it offers unmatched flexibility in manufacturing and customization for specific applications.

Amorphous silicon is reliable indoors and requires the least amount of attention after installation due to its unique design and physical properties. System integrators, device manufacturers and end users implementing amorphous solutions will no doubt be able to extend battery life and ultimately reduce solution maintenance costs.

Frank Jeffrey, CEO of PowerFilm Inc., has been involved in the solar community for over 40 years and helped found the company in 1988. Prior to founding Iowa Thin Film Technology (now PowerFilm Inc.), Dr. Jeffrey served as a Senior Physicist of both 3M and the Solar Energy Research Insititute (Now NREL), developing amorphous-silicon solar technology. He has a BS and PhD, both in physics, from Iowa State Univ.