This content was provided by Bourns

Transparency Market Research analysts predict that the global lithium-ion battery market is poised to rise from $29.67 billion in 2015 to $77.42 billion in 2024 with a compound annual growth rate of 11.6 % (Fig. 1). They note that growth has already spread from the now ubiquitous consumer electronics segment to automotive, grid energy, and industrial applications. While billions of dollars are continuing to be invested in the search for safer, longer lasting and higher energy density batteries, it is difficult to see lithium-ion based batteries being replaced anytime soon.

1. Global lithium-ion battery market growth estimate.

As they continue to grow in popularity, they will enjoy further cost reductions because of the economies of scale, especially when employed in additional applications such as electric vehicles and stationary storage systems. It will be difficult for any new battery technology to compete commercially with such entrenched use.

Even with such impressive growth projections, potential safety issues remain that must be taken into consideration. Battery problems continue to be headline news, indicating that even the largest of companies can experience issues with their lithium-ion battery designs.

One of the primary limitations of the lithium-ion battery is the need for protection circuits to maintain the voltage and current within safe limits. These batteries need to be well protected against overcurrent and overtemperature threats. In addition, battery suppliers continue to look for ways to streamline manufacturing to keep their costs low in such a competitive environment.

This article will present the primary issues involved in designing overcurrent and overvoltage protection for lithium-ion batteries. It will also introduce a new series of overcurrent and overtemperature devices that match the expanding needs of today’s smaller electronic designs, and also give battery suppliers a way to cut manufacturing steps and costs.

Effective Battery Protection Technology

A popular approach for providing a safety circuit to a lithium-ion battery pack is a miniature Thermal Cutoff Device (TCO), also known as a mini-breaker. TCOs are designed to provide accurate and repeatable overcurrent and overtemperature protection. Meeting the changing protection demands in next-generation lithium-ion battery packs has led to the evolution of TCO technology as well.

TCOs combine two common circuit protection technologies, a PTC and a bimetal switch. Bourns, as one the leading suppliers of TCOs, has leveraged its precision metal stamping, plastic injection molding, and high-end assembly experience to turn these ubiquitous technologies into an effective circuit protection solution.

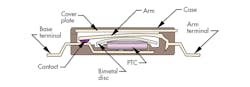

Figure 2 below provides a simple schematic of the construction of a Bourns miniature TCO. The two terminals (arm terminal and base terminal) are connected in a normally closed position to allow current to flow through the device. The contact point between both terminals serves a critical function and must provide high precision contact resistance, which can be as low as 2 milliohms max., in some model families.

2. Construction of Bourns mini-breaker.

How it Protects

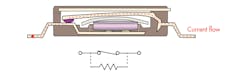

Figures 3 and 4 illustrate how miniature TCOs mechanically provide protection to the circuit. Under normal conditions, current flows though the arm terminal, down through the very low resistance contact point, and out through the base terminal. Key to any battery application is low resistance—hence, the need for the right contact resistance between arm terminal and base terminal.

3. Miniature TCO in the normally closed position.

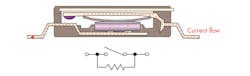

4. Mini-breaker triggered open.

The TCO can be triggered by either an increase in the environmental temperature or by excessive current flows. Once the trip temperature has been reached, the bimetal disc heats and flexes, and this motion causes the arm to open (Fig. 4). If the TCO used only a bimetal disc for its protection, the arm would quickly close as the temperature cooled. However, the benefit to the design of the Bourns miniature TCO is that the PTC operates in parallel with the arm terminal.

When the bimetal disc causes the arm to open, current flows though the bimetal disc and into the PTC. This current causes the PTC to act like a current-limiting heater, which provides sufficient heat to keep the bimetal disc flexed and the arm open. The combination of the bimetal disc and the PTC prevents oscillating opening and closing of the TCO arm. Instead, this design allows the arm to remain open until a lower and safer temperature level is reached (between 40 °C and 10 °C below the lower specification limit of the TCO), at which point the arm will reset. As part of UL 60730 testing, the opening and closing mechanism of most mini-breakers are tested up to 6000 cycles.

Benefits of Surface-Mount Devices

Electronics assembly has shifted to mostly high speed automation, and the pick and place of surface mount components onto printed circuit boards (PCBs) is fundamental to this evolution. Reducing the number of parts that require special handling and choosing components with process requirements in mind will help ensure fewer passes through equipment and fewer extraneous steps in the assembly of the PCB.

Up until now, Bourns miniature TCOs came in an axial leaded format to allow them to be welded to the terminals of the battery cells. The battery cell terminals are typically made from aluminum tabs, so the mini-breakers are usually welded to nickel tabs first before those nickel tabs are welded to the battery cell terminals. It is a common practice for battery pack manufacturers to outsource the welding of these nickel tabs to sub-assembly manufacturers, where one nickel tab would be welded to the cell before being shipped to the packer, or assembly house.

Finally, the packer would assemble the battery cell on the PCB and weld the other nickel tab to the PCB. These steps take extra time and coordination in the supply chain, not to mention the specialty welding required.

These extra manufacturing steps are no longer necessary with the introduction of Bourns’ new SA Series surface mount miniature TCOs. The new SA Series enables battery suppliers for the first time to mount TCO protection directly onto the battery management PCB (Fig. 5). For battery pack manufacturers, that means the TCO can be processed through the standard pick and place operation with the other components, such as battery management ICs, MOSFETS, NTCs, resistors, PTCs, diodes, and fuses. Where in the past the mini-breaker required the specialized welding operation, this can be eliminated with the use of Bourns Model SA Series TCO and simply be packed in a standard tape and reel for printed circuit board population. By placing the TCO directly onto the PCB, battery suppliers eliminate both the welding and the insulation taping process. The process lead time thereby can be reduced to a mere two weeks with the Bourns Model SA Series.

5. Suppliers and time reduction.

Use of a surface mount miniature TCO also provides a significant cost savings for battery pack manufacturers, estimated to be up to 30% compared to existing welded nickel tab solutions. Elimination of the nickel tabs also helps reduce the resistance of the overall battery pack, which contributes to improved battery life.

The bottom line is companies can realize tangible benefits by incorporating the Bourns surface-mount SA Series TCO because its use reduces opportunities for errors in the supply chain process. The possibility of a bottleneck waiting for specialized resources to perform manual steps is removed. No additional potential human error is introduced into the packaging, shipping, or assembly process. The defect rate and prospect of damage during transit should also be reduced as the TCO is shipped securely in tape on a reel rather than as welded to the battery.

Key Battery Protection Features

The trip temperature of a TCO is a key specification to battery pack manufacturers, and Bourns has developed the ability to target specific trip temperature values for the SA Series. The combination of both the composite bimetal material and the precision forming of the bimetal disc allows Bourns to target trip temperatures from 72 °C to 85 °C within a ±5 °C accuracy.

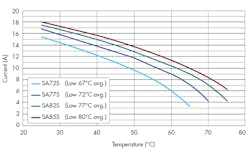

Miniature TCOs trigger from a combination of temperature and current. The ambient temperature will rise from the I2R Joule heating (or resistive heating) caused by the interactions of the electrons from the electric current and the atomic ions the terminals causes. Hence, TCOs at lower ambient temperatures can hold significantly higher currents than those at higher ambient temperatures. The graph in Fig. 6 illustrates the ambient current impact on operating currents for various Bourns SA Series models.

6. Ambient temperature impact on mini-breaker operating currents.

The maximum leakage current specification is determined by the PTC used in the TCO. When the TCO opens, it does not cut the current. Instead, the current path changes and travels through the parallel circuit of the bimetal disc and the PTC. The PTC has an internal resistance that is used to heat the bimetal disc and the leakage current is a result of the PTC let-through current. For the new SA series, this let-through current is 200 mA maximum at 25 °C.

PCB Mounting Recommendations

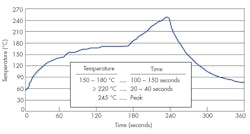

TCOs are thermally sensitive devices by design, so the ability to reflow solder using the Bourns SA Series is a technological breakthrough. The SA Series can be mounted using industry common reflow profiles for lead-free solders and the recommended reflow profile is outlined in Fig. 7.

7. Recommended reflow profile for an SA series mini-breaker.

Accommodating multiple components when populating circuit boards is often required. Bourns offers a variety of profile ranges with the SA Series for reflow soldering:

- 150 ~ 180 °C − 100 ~ 150 seconds

- ≥ 220 °C − 20 ~ 40 seconds

- 255 ~ 260 °C − 5 ~ 10 seconds

It is important to note that TCOs contain precious components as part of their mechanical switching mechanism. Hence, a mounting load of less than 5 N is recommended to help prevent any negative influence on the function of the TCO.

Conclusion

In many industries, time to market ultimately determines the success or failure of a product. By reducing production time and cost by incorporating the Bourns Model SA Series TCO, battery pack manufacturers now have a new resource to successfully meet production targets and deadlines. Designers can now incorporate the necessary overcurrent and overtemperature protection while reducing the previously required time and manufacturing resources overhead.

As lithium-ion battery pack applications continue to grow in use and sophistication, so too must protection solutions match their increasing requirements. Bourns has extensive expertise and is a proven supplier of battery protection devices, with more than 2.7 billion units sold. The new surface mount SA Series is Bourns’ answer to meet the lithium-ion battery pack industry’s demand for disruptive technologies that can deliver needed performance while helping to reduce overall product costs.