Power Electronics Cultivate a Second Life for Ex-EV Batteries

This article is part of the TechXchange: EV Battery Management.

The lithium-ion (Li-ion) batteries at the heart of electric vehicles are designed to remain in use for tens of thousands of miles and last for a decade at a time. But they’re bound to have a hard life.

The batteries—the most expensive building blocks in the EV—are subject to harsh temperatures, severe vibrations, and other rigors of the road. And they lose capacity through constant charging and discharging cycles at varying rates.

Even when they no longer meet EV quality standards, these batteries can be reconfigured for a second life before being discarded. One possibility is to use them as stationary energy storage for electric grids that increasingly run on solar, wind, and other renewables, storing excess power for times when the sun stops shining and the wind stops gusting—or when demand for electricity spikes.

Power electronics are playing a key role in this shift to a more sustainable grid powered by renewables, said Adam White, head of the power and sensor systems division at Infineon.

Case in point, the company is working with startup STABL Energy to build large-scale energy-storage systems using ex-EV batteries. STABL incorporates Infineon’s 100-V MOSFETs in the modular inverters that sit inside its industrial and grid-level storage systems. Founded in 2019, the startup hopes to extend the lifecycle of these batteries by repairing and reusing them as intermediate energy storage.

These energy-storage systems can range in capacity from tens to many hundreds of kilowatt/hour (kWh) capacity and are being tapped to supply standalone power for everything from buildings to fast EV chargers.

As part of a smart grid, peak shaving, buffer storage, and distributed load management are also possible with energy-storage systems like those from STABL. They can also serve as temporary storage for solar energy or emergency backup systems for data centers.

The More Modular, the Better

Batteries tend to be unfit for use in electric vehicles as soon as they hit 80% of their original capacity or support a resting self-discharge rate of more than 5% per day, according to a report from research and consulting firm McKinsey.

Because these batteries are often severely depleted after several years—and even more than a decade—of constant operation, STABL is working to wring as much power out of them as possible.

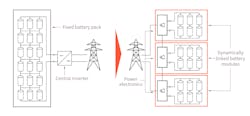

Today, most energy-storage systems are assembled from sets of identical battery modules that are recovered from old EVs and then permanently wired to each other in a fixed configuration.

At the core of these systems is a central inverter that converts the direct-current (dc) voltages from the all-in-one battery pack, into alternating current (ac) for the grid. These inverters tend to use IGBTs that can handle the high, lethal-to-the-touch voltages of the battery pack, which usually ranges up to 800 V. With IGBTs, the tradeoff tends to be energy efficiency.

Instead of binding the battery modules together statically, STABL designed a dynamic interconnect system that works with a mix of modules with various voltages and capacities, rendering the central inverter obsolete. Featuring a current rating of up to 100 A, STABL’s modules top out at 60 V and use 100-V MOSFETs with lesser switching voltages and frequencies to reduce losses relative to IGBTs.

The key to STABL’s heterogeneous battery storage system is a new “modular multilevel inverter” that pumps out the desired sinusoidal output voltage by connecting individual battery modules in a series.

"Compared to conventional systems, this reduces loss by up to 70% and cuts both operating costs and CO2 emissions by up to 40% per year," said Arthur Singer, founder and co-CEO of STABL.

Distributed Power

Modular multilevel inverters are widely used in the world of high-voltage dc transmission. But the startup touts its technology as being uniquely designed for energy-storage applications.

Per STABL, most inverters use pulse-width modulation (PWM) to control the average output power of the system by switching on and off the MOSFET, IGBT, or other power FET for different periods of time.

To reduce electromagnetic interference (EMI) and other power anomalies, the sinusoidal voltage that the system feeds to the load must be smoothed by a line filter, which reduces efficiency and causes losses.

STABL simulates the sinusoidal voltage by connecting the battery modules in series and switching them one after the other. The step voltage—or “staircase” voltage, as the company calls it—more closely resembles the desired mains voltage than the output of a traditional central inverter. This also means that the filter that sits between the grid and the energy-storage system can be made more compact, which helps keep power losses in check, said STABL.

This distributed architecture makes it possible to connect ex-EV batteries with different residual capacities to public power grids more flexibly, even in larger quantities, without a central inverter.

The technology is also said to prevent a single point of failure in the system. STABL’s modules can automatically detect when a battery deviates from its normal state and then isolate the defective unit from the rest of the device, saving it from having to be completely shut down.

The company said it chose the 100-V MOSFETs from Infineon’s OptiMOS 5 family due to their low on-resistance (RDS(on)), high thermal performance, and high reliability.

Easier Energy Balancing

As major EV manufacturers roll out millions of electric cars, trucks, and other vehicles over the next decade, a secondary market for retired batteries is bound to take shape, according to industry analysts.

Another issue STABL is trying to address with its modular inverter concerns the widely varying residual capacities of ex-EV batteries, which can limit the capacity of the overall energy-storage system.

The cells inside a battery pack are rarely identical. They usually come with slight differences in capacity, internal resistance, self-discharge rate, and many other properties that are largely due to manufacturing inconsistencies. Thus, different cells in the pack will have less charging capacity than others.

Moreover, the maximum capacities of the cells will drift apart over time through constant use. The weakest cell connected in series limits the extent to which the remaining cells can be charged.

Despite imbalances in storage capacity, the cells will all have the same charging and load current. So, during charging, not all cells will be fully replenished at the same time, and during discharging, the weakest battery cells will also be depleted first. Then, even though capacity remains in the other cells, the battery pack will stop supplying power to the load. The stress of over- or under-charging a Li-ion battery can cause premature termination of charge and a reduction in useful lifespan.

The level of charge in the battery cells can be equaled out—or even redistributed—through active or passive cell balancing. But such technology costs power and adds to the system’s bill of materials (BOM).

If the new modular architecture from STABL works, the weak cells in the series no longer affect the capacity of the larger energy-storage system—only the capacity of a single battery module.

The modules are also charged and discharged depending on their state of charge (SOC). Thus, the SOC of the modules automatically align with one another, increasing the system’s capacity.

Power Electronics Edge?

STABL is pushing its modular inverter technology at a time when EV batteries are about to become more plentiful.

By 2030, more than 300 gigawatt-hours (GWh) of EV batteries will be retired and become ready for reuse globally, according to Circular Energy Storage Research and Consulting. That would correspond to a year of power consumption for around 75,000 four-person households.

But not everyone agrees on what to do with these former EV batteries. Redwood Materials, founded by ex-Tesla CTO J.B. Straubel, is working on ways to recycle batteries more efficiently and recover the valuable metals and other raw material inside them, including lithium, cobalt, nickel, and copper.

But STABL’s unique architecture may provide a more practical way to use these batteries in energy-storage equipment. Pilot systems have been connected to the grid and put into operation in Europe.

In Switzerland, an initial energy-storage unit assembled out of 27 discarded EV batteries serves as temporary storage for solar energy used to power a residential area. The unit comes with a nominal capacity of 98 kWh.

Read more articles in the TechXchange: EV Battery Management.