Why Do You Need Low Iq with Power-Line Communications?

This article is in the TechXchange: Why Low Iq is the Smart Thing to Do.

Members can download this article in PDF format.

What you'll learn:

- An alternative method to lower Iq in power-line communications.

- Why RS-485 is often used in PLC.

- A look at simulating an automatic meter reading system.

This article puts the spotlight on low quiescent-current (Iq) consumption in power-line communications (PLC), and we’ll start by looking at an overtemperature protection (OTP) circuit for PLC applications. When compared to the traditional structure of a comparator, the quiescent current and the transistor consumption of the circuit is effectively reduced (Fig. 1).3

However, it will have limitations when using a bipolar junction transistor (BJT) process. A proposed option has a current distribution structure with a positive loop, which will realize state switching if the temperature exceeds the threshold or recovers. Traditional structures, with integrated comparators in the CMOS process, will not be able to lower quiescent current adequately.

This alternate method chosen will minimize quiescent current (Iq) and transistor consumption with the new circuitry. In addition, since no comparator now exists in this design, there is also no need for a reference voltage. This elimination of the comparator will also lower the chip Iq. Thus, the process and voltage stabilities of the circuit are now improved.

The new OTP circuit for this lower-Iq design can now be implemented in a silicon-on-insulator (SOI) bipolar junction transistor (SOI-BJT) process instead of just a BJT process. The OTP circuit now will rely on a line-driver IC for verification.

The module will now consume 5-µA Iq, which will only account for 0.02% of the whole chip. The measured maximum temperature drift of the circuit is 0.167°C/V while under the power-supply voltage range of 6 to 30 V. The average hysteretic temperature drift of six random sampled chips is now 0.15°C.

Using RS-485 Communications Over PLC

Various applications use RS-485 communication over PLC, including electronic door locks, HVAC system controllers, elevator call button operating panels, and elevator main control panels, just to name a few We’ll look at this technique with a simulation model.5

Communication buses, such as the proprietary bus in elevator systems, interface with the call buttons used inside an elevator with its main controller. The RS-485 bus has more throughput and can easily interface with more networks than just the RS-485 bus. A next-generation solution may be an easier-to-install wired design with lower cabling costs.

Texas Instruments has a PLC solution that employs an RS-485 simulation reference design (TIDA-010035) that leverages RS-485 communication over power buses.

The THVD8000, an RS-485 transceiver, has on-off keying (OOK) modulation and demodulation built into PLC. OOK is the simplest form of amplitude-shift keying (ASK) modulation, which represents digital data as the absence or presence of a carrier wave. A binary one signifies the presence of a carrier for a specific duration, whereas a binary zero signifies the absence of a carrier for the same duration.

Modulating data onto existing power lines will enable power delivery and data communication to share a common pair of wires. This will significantly reduce system costs.

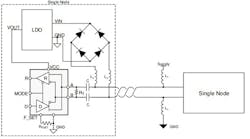

Figure 2 shows the optional rectifier network pictured on the bus lines. The network of diodes can ensure that the node properly receives power from the bus wires, even if the lines get swapped. Termination resistance (RT) isn’t required for this device functionality. However, it may improve signal integrity for some applications by reducing reflections that can occur at the cable end points.

Quiescent supply current for the THVD8000 RS-485 transceiver with built-in PLC is:

- Transmit mode: 5 mA max.

- Receive mode: 6 mA max.

Application: Automatic Meter Reading

An automatic energy meter reading system, which is based on PLC, was successfully simulated in Reference 6. Thanks to the use of a microcontroller, readings are automatically transmitted to the server through the power lines. This method helps improve meter accuracy and reduce meter maintenance costs.

The system is designed to work on single-phase, but it can also be further extended to work in a three-phase system. Transmission distance for the designed power-line modem (Reference 6) is as far as 300 m. That can be improved by upgrading the power-line modem.

Even though new modern communication technologies are available for billing data, using an existing power line is typically the most economical way. This is a readily adaptable system, as compared to most other technologies, and is efficient.

Summary

The main advantage of power-line communications technology is eliminating the difficult task of installing additional dedicated communication cables. This article has focused on low Iq applications in PLC and the OTC circuits for PLC with RS-485 communications.

PLC technology is mostly used in high-voltage power lines (10 kV or above, and low-voltage 220- or 380-V power lines) for remote meter reading. Other uses of PLC have been expanding into power-distribution lines for load control as well as into households to control lighting, HVAC, and alarm systems.

Another key application is protective relaying for transmission lines. This can be done by selecting a channel, employed in line protection, to ensure that both ends of a circuit are cleared at high speed for all types of faults. A PLC channel will also be able to provide remote tripping functions for power transformer protection, remote breaker failure relaying, and shunt reactor protection.

Read more articles in the TechXchange: Why Low Iq is the Smart Thing to Do.

References

1. ISL15110 - PLC MIMO Line Driver | Renesas.

2. Broadband Power Line Communication - an overview | ScienceDirect Topics.

3. “A 5-μA Low Power Over-Temperature Protection Circuit With High Voltage and Process Stabilities for Line Driver in PLC Applications,” IEEE Transactions on Circuits and Systems—II: Express Briefs, Vol. 70, No. 4, April 2023.

4. “AFE031 Powerline Communications,” Analog Front-End, Texas Instruments.

5. “Power Line Communication Using RS-485 Simulation Reference Design,” TIDUEI9, November 2018.

6. “Automatic Meter Reading using Power Line Communication,” IJSTE - International Journal of Science Technology & Engineering, Vol. 2, Issue 10, April 2016.