New PMIC Paves Way for Dual-Source Energy Harvesting

What you'll learn:

- How e-peas' new energy-harvesting PMIC can extract power from a pair of sources.

- What does a PMIC do?

- Key protection mechanisms in the new PMIC.

The IoT world is dominated by single-use batteries that must be replaced or disposed of after their power runs out and rechargeable batteries and other storage devices that require continuous reloading.

However, a new generation of power-management ICs (PMIC) is opening the door for IoT devices to replenish themselves using energy harvested from the environment, thus reducing or eliminating the need for batteries.

Energy harvesting extracts ambient energy in the form of light, motion, vibrations, heat, radio waves, and even blood sugar from human skin out of the environment and converts it into power to recharge a battery or supercapacitor. Now, e-peas is raising the bar with what it claims is the first PMIC that can harvest energy from two independent sources at the same time, refilling a battery or storage device while protecting it from overcharging or other permanent damage.

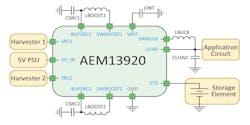

Suited for battery-powered IoT devices where it’s critical to expend as little energy as possible, e-peas' AEM13920 is specifically designed to extract energy from any combination of two sources at once: light (captured by photovoltaic cells); vibrations and pressure (piezoelectric devices); temperature differentials (thermoelectric generators); motion or other forms of kinetic energy; radio frequency (RF) signals; among others.

The Role of PMICs in Energy Harvesting

Energy harvesting is not for everything. In general, it can only supply sufficient power to battery-powered devices—including wireless sensors on factory floors, smart door locks and light switches, and peripherals and other consumer devices—that run at relatively low duty cycles and consume only minute amounts of power.

Instead of requiring constant power delivery, these loads remain in standby mode for long intervals and only turn themselves on infrequently to save power, since replacing or recharging the batteries inside them can pose a challenge.

One of the building blocks of any energy-harvesting system is a PMIC that can carefully manage the microwatts to milliwatts of power scavenged from the world around it and then maximize the power transfer from source to the load with limited resistance or loss. The IC’s role is to convert the alternating (AC) or direct current (DC) from the energy harvester, regulate it to supply only what’s required to run the device, and then store excess energy in a rechargeable battery or storage unit.

Storing the excess energy in the rechargeable battery enables the device to operate continuously even when an energy source may not be readily available—for instance, when solar-powered devices are in the dark.

In general, these energy-harvesting ICs integrate AC-DC or DC-DC converters to manage the power and recharge the Li-ion or other types of batteries, providing regulation and protection for the storage device.

Many of the latest energy-harvesting ICs can also dynamically adjust the electrical operating point of the device to harvest as much ambient energy as possible. They do so by supporting maximum power point tracking (MPPT), a technology used with variable power sources to maximize the extraction of ambient energy as conditions vary. It’s widely used by solar, wind, and other renewable-powered grid equipment.

Every energy-harvesting device features an open-circuit voltage—the maximum amount of voltage it can supply, which occurs when there’s no current—and a short-circuit current—where the current increases to the point when the voltage is zeroed out. In between, the amount of available voltage depends on how much current it’s producing. As the current rises, the voltage it produces falls accordingly.

The challenge: how efficiently power is transferred from the energy source to both the battery and the load depends on a host of factors, including the environmental conditions and the operating characteristics of the device itself.

As these conditions vary, the load characteristics—specifically, the impedance—that will deliver the best power efficiency also vary. The PMIC runs MPPT to carefully manage the flow of current from the energy source so that the system is operating at a voltage that maximizes its power output.

Advantages of Dual-Source Energy Harvesting in the IoT

e-peas is trying to overcome the challenge of existing energy-harvesting ICs on the market that are designed to harvest energy from one source at a time; for instance, solar or vibrational, but not both.

But the new chip’s most distinctive feature is its ability to support inputs from any pair of independently harvested sources of energy at once. e-peas said the feature ensures continuous energy harvesting, even when one source is unavailable or inefficient, making sure a constant flow of power is available when a system needs it.

Dual-source energy harvesting enables the system to switch between different sources depending on the operating requirements of the device and the most abundant form of ambient energy.

Harvesting energy from several sources at once also gives customers more design flexibility, according to the company. For instance, a remote control could have separate solar cells on its front and back to maintain a constant input whether the device is left face up or face down.

e-peas stated that the power IC also paves the way for customers to mix and match different methods of energy harvesting, choosing the sources best suited for a specific device. For instance, a smart light switch in a building could use mechanical energy for relatively short operations, while mechanical or light energy stored in a battery could take care of longer operations, like downloading and installing a firmware update.

Moreover, the AEM13920 reduces the complexity and cost of energy-harvesting systems in IoT devices since all of the functions required to store and harness energy from external sources are implemented in a single IC.

Key Features of the New Energy-Harvesting IC

Naturally, the new PMIC’s main job is to recover as much energy from the source as possible, and power efficiency is key when handling the tiny amounts of power that stem from energy harvesting.

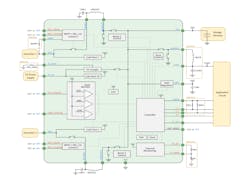

To prevent power from being wasted, the AEM13920 can convert power from source to storage and from storage to load at more than 90% efficiency. It supports MPPT on each independent source to maximize the amount of power pulled from its surroundings. With its cold-start circuit, it can start operating with an input voltage as little as 275 mV at a minimum of 5 µW of power.

Dual boost converters are in charge of converting the voltage from each energy source independently and supplying it to a battery. A separate buck regulator with efficiency above 90% delivers a regulated output voltage from the battery of between 0.6 and 2.5 V, depending on the device requirements, and it outputs up to 100 mA of current. Constant source-voltage regulation is supported, too.

e-peas said the PMIC also features an input for 5-V power supplies, which can be used for fast-charging a battery or storage element in the event of a prolonged period of operation without any harvested energy.

Housed in a 5- × 5-mm, 40-pin QFN package, the PMIC is compatible with many types of rechargeable batteries, including lithium-ion (Li-ion), lithium-ion polymer (LiPo), lithium iron phosphate (LFP), and others.

The I²C interface makes it possible to control every setting of the AEM13920 from the host MCU.

The Importance of Battery-Protection Mechanisms in PMICs

Another feature of the energy-harvesting PMIC is called average power monitoring (APM), which allows it to measure the total energy transferred from each energy source to storage and the total energy supplied to the load. In turn, the MCU at the heart of the device can calculate the state of charge (SOC) of the battery, supercapacitor, or other storage device, and monitor system operation in detail.

The power IC is also equipped with system monitoring and protection features. These are indispensable in any battery-powered device, because overcharging a battery can cause permanent damage—or even explosions.

The temperature of the battery or other storage device powered by the energy-harvesting IC is monitored to protect against overtemperature and undertemperature during both charging and discharging cycles.

To protect the battery from becoming overloaded or too deeply discharged, the AEM13920 has a selectable overcharge voltage of up to 4.1 V and a selectable overdischarge limit of up to 3.0 V.

Despite pushing the envelope in energy-harvesting innovation, e-peas isn’t alone in tackling the unique power-management needs of ultra-low-power IoT or even off-mains devices without batteries at all. Early this year, Nexperia rolled out a new power IC that promises to make energy harvesting easy for IoT devices by managing everything from harvesting the energy to storing it in batteries and releasing it to a system.