Concrete + Carbon Black Supercapacitor Promises Large-Scale Energy Storage—Maybe

What you’ll learn:

- How researchers built a supercapacitor from concrete and carbon black.

- Detailed theory and analysis, and the performance they achieved.

- The possible implications of this energy-storage component.

The high-density energy stage has always been a challenge, whether accomplished using electrochemistry and batteries, electric fields and supercapacitors, gravity-based systems of various types, or any of the many other options.

Now, a team of researchers at MIT and the affiliated Wyss Institute for Biologically Inspired Engineering claims to have devised a technical and cost-effective solution using relatively mundane materials: concrete, carbon black, water, and potassium-chloride salts. (Note: Carbon black is a common industrial material produced from incomplete combustion of heavy petroleum products, and contrary to misconceptions, is very different than charcoal.)

The Science Behind Carbon Black in Concrete: A Potential New Paradigm in Energy Storage

Their approach uses a cement-based material with an extremely high internal surface area due to its dense, interconnected network of conductive material within its bulk volume. The researchers achieved this by introducing carbon black—which is highly conductive—into a concrete mixture along with cement powder and water, and letting it cure.

The water naturally forms a branching network of openings within the structure as it reacts with cement, and the carbon migrates into these spaces to make wire-like structures within the hardened cement. These structures have a fractal-like structure, with larger branches sprouting smaller branches, and those sprouting even smaller branchlets, and so on. In the end, there’s an extremely large surface area within the confines of a relatively small volume.

The material is then soaked in a standard electrolyte material, such as potassium chloride salt, which provides the charged particles that accumulate on the carbon structures. The researchers found that wo electrodes made of this material, and then separated by a thin space or an insulating layer, form a very powerful supercapacitor.

The technical paper and its supplement provide an extreme “deep dive” electrochemical analysis—it’s among the most detailed I’ve seen for this type of project. Other analysis included Raman spectroscopy to assess what’s going on inside the supercapacitor, in addition to other sophisticated tests (after all, this is MIT).

How Did the Concrete Supercapacitor Perform?

Of course, it’s important to initially judge these supercapacitors by their top-tier performance metrics, such as capacitance or energy storage per unit volume and weight (the latter factor isn’t as critical here given the material and its intended application). The paper contains many detailed graphs, but I found them hard to compare in our more-customary context (Fig. 1).

1. Capacitance measurements and analysis: (A) (1) An electric double-layer capacitor (EDLC) composed of (2) two polished, electrolyte saturated carbon-cement electrodes (thickness d) separated by (3) a glassy fiber membrane soaked in the same electrolyte (1M KCl), and covered by (4) conductive graphite paper. The electrodes are (5) pre-stressed in (6) a closed cell to improve contact between the charge collectors and the electrodes (31). (B-1/B-2) Steady-state cyclic-voltammetry (CV) measurements of current, I, during cyclic charge/discharge at different scan rates, u = U0 = t0, for two carbon-cement electrode samples prepared with different carbon blacks, water-to-cement ratios, and electrode thickness: (B-1) PBX 22.4 (0.8) 0.18 cm, and (B-2) Ketjenblack 12.8 (1.4) 0.60 cm). (C-1) Steady-state galvanostatic charge-discharge (GCD) measurements of voltage U when a constant current I0 is applied and held constant over time t0, and then removed until U = 0. (C-2) Fractional exponent α as a function of applied current in GCD experiments. (D-1/D-2) Convergence of capacitance measurements from CV-tests and GCD-tests toward a rate-independent specific capacitance C0 = mnCB, with mnCB the mass of carbon black in the electrode. The dashed lines represent a 95% CI. (E) Applied to eight different carbon-cement electrode materials of different carbon blacks, mix designs, and electrode thickness, a characteristic scaling of the rate-dependent CV capacitance is obtained, indicative of the high-rate capability of the electrode materials. (F) Hardness vs. capacitance plot demonstrating that high-rate capability can be achieved with high water-to-cement electrode materials, but at the expense of the material strength.

However, the team did provide one relatable metric, and calculated that a 45-cubic-meter block would have enough capacity to store about 10 kilowatt-hours of energy—that’s a density of about 0.22 kWh/m3—which is considered the average daily electricity usage for a household. Since the concrete would retain its strength, they note that a house with a foundation made of this material could store a day’s worth of energy produced by solar panels or windmills and allow it to be used whenever needed.

The researchers were extremely optimistic and positively effusive about the prospects for this supercapacitor as a solution to the electric-energy storage (ESS) challenge, with considerable amount of speculative extrapolation about how it could be used in building, structures, and more as a no-hassle, almost-free storage medium.

Speculative Prognosis and More Experimentation

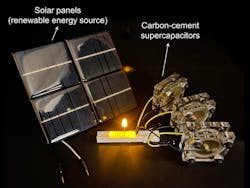

But reading the technical paper, it turns out that most of this is just that: extrapolation and speculation. Thus far, they have only built small supercapacitors roughly the size of some button-cell batteries, about 1 cm across and 1 mm thick, that could each be charged to 1 V. They then connected three of these in series to demonstrate their ability to light up a 3-V LED (Fig. 2).

2. The concrete and carbon black energy-storage material was tested with three small-scale units wired in series, charged by a solar panel, used to power a small LED.

Team member Prof. Franz-Josef Ulm maintains that the system is very scalable, as the energy-storage capacity is a direct function of the volume of the electrodes. He said, “You can go from 1-mm-thick electrodes to 1-meter-thick electrodes, and by doing so, basically you can scale the energy storage capacity from lighting an LED for a few seconds, to powering a whole house.”

He may be right, as concrete mixing, pouring, and curing are well-established processes. They plan to build a series of larger versions, starting with those about the size of a typical 12-V car battery, then working up to a 45-cubic-meter version to demonstrate its ability to store a house-worth of power. They also investigated the tradeoffs between carbon black percentage on energy storage versus material strength, and found that 10% seemed to be the optimum ratio.

However, the general history of battery and supercapacitor chemistries and processes is that they don’t scale-up easily or well. There’s a long list of “breakthroughs” that worked at the small scale, but were hard to produce in larger sizes or volumes, or where performance attributes as well as consistency and reliability dropped off significantly as size increased.

For example, migration of carbon black here may not happen at a larger scale as it does at a small scale. (Personal note: Given the amount of speculative hyperbole associated in this story, the cynic in me wonders if future funding opportunities play a role.)

The work is presented in their analysis- and equation-laded seven-page paper “Carbon-cement supercapacitors as a scalable bulk energy storage solution” published in the Proceedings of the National Academy of Sciences (PNAS), a peer-reviewed journal of the National Academy of Sciences (NAS); there’s also an 18-page “Supporting Information” file. The work was supported by the MIT Concrete Sustainability Hub, with sponsorship by the Concrete Advancement Foundation.