An Engineering View into High-Voltage Technology

This article is part of the TechXchange: Power Supply Design.

Members can download this article in PDF format.

What you’ll learn:

- Main steps in designing high-voltage systems.

- Attaining high reliability and high efficiency for high voltage.

- What are Pockels cells?

- A look at Marx pulse generators and a proposed boost version of the generator.

Fast-growing power consumption worldwide needs innovative thinking by design engineers, ultimately leading to more efficient designs that can make renewable energy and electrification technologies far more attainable.

When designing high-voltage applications, there will be a unique set of challenges. This is why power conversion, current and voltage sensing, isolation, and real-time control technologies must coalesce to simplify high-voltage designs. In turn, it will help designers reach the highest levels of reliability and efficiency.

Simplifying High-Voltage Designs

Designing front-end power supplies will lead to some unique challenges stemming from the high-voltage requirements that must be met. Designers should always first seek out design tools that will simplify their high-voltage design applications.

The following three steps are critical in the design of high-voltage DC-DC or AC-DC circuit designs:

- Understanding your system requirements: First determine the proper voltages for your design, i.e., region-specific voltages such as in the U.S. 120 V, China 220 V, Japan 100 V, and U.K. 230 V. Maybe you’re designing an on-board power supply or charger application. What, if any, are the isolation requirements? Will tight output voltage regulation be needed? On this front, TI’s WEBENCH High-Voltage Power Designer can be a big help.

- Choose the best control/topology scheme: Half-bridge and forward topologies usually will be used at power levels from 100 to 500 W; full-bridge topologies can serve power levels greater than 500 W. Designers may want to design the controller to operate in continuous conduction mode (CCM) (this is where the magnetizing current in the transformer will not reach zero), discontinuous conduction mode (DCM) (where the magnetizing current reaches zero and stays at zero until the next switching cycle), or transition mode (TM) (where the magnetizing current reaches zero and the following switching cycle starts promptly). CCM is usually for higher power levels; DCM and TM will provide lower-loss solutions.

- Design the transformer: A properly designed transformer will lead to a solid high-voltage power-supply design in your application. The transformer is usually one of the main energy-conversion elements in any high-voltage design, and it provides isolation between the primary and secondary. Designers may also be able to find a transformer that already exists and fits their application.

High-Voltage Applications

High-voltage power supply for an X-ray computed tomography (CT)

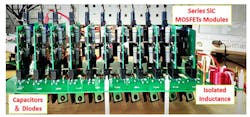

CT is a computerized X-ray imaging procedure that generates a narrow beam of X-rays directed toward a patient’s body and then is promptly rotated around the body.3 This method produces signals that are processed by the CT machine’s computer, which will then generate cross-sectional images, or “slices” known as tomographic images. These images will allow a clinician to have access to a more detailed 3D view than a conventional X-ray. Figures 1 and 2 show the power-supply inverter chassis.

Electric vehicles

Vehicle electrification is fast becoming a more widely accepted technology (Fig. 3).6,7 Today, electric vehicles (EVs) are powered via 400- or 800-V battery packs that enable faster charge times while extending driving range.

What’s a Pockels Cell?

A Pockels cell is defined as an electro-optic device (just like an electro-optic modulator) that’s made up of an electro-optic crystal through which light is transmitted. The polarization direction of that light will be controlled by the voltage that’s applied to the crystal. The voltage necessary for a Pockels cell depends on the type of cell, the light’s wavelength, and crystal size. Voltage range is typically on the order of 1 to 10 kV.

The Pockels Effect explains the behavior of the Pockels cell. An applied constant or variable voltage (electric field) to the crystal will produce linear changes in the birefringence of the crystal. The Pockels cell will operate as a voltage-controlled wave plate when applying a constant voltage.

By applying a variable voltage, designers can use a Pockels cell to vary the phase delay through the crystal. Pockels cells are necessary components in optical devices such as Q-switches for lasers and electro-optical modulators (EOMs).

In the application in Figure 4, the Pockels cell functions as a quarter wave plate, in which linearly polarized light gets converted to circularly polarized light. Adding a Brewster's window (on the left side of Figure 4) will enable a change in polarization that will convert to a change in the intensity of the light beam, via transmitting just on the p-polarized vector component.

An integrated optics Pockels cell (IOPC) was created for measuring high-voltage electric fields.8 Sensors of this type have proved capable of metering high-voltage AC signals with less than 0.3% error. They can also be used to monitor lightning impulses with less than 6% error.

The Marx Pulse Generator

Marx generators are quite impressive systems for efficient voltage multiplication. With a short pulse generation, the Marx generator must operate close to its critical damping as a result of a balance between an overshoot and voltage efficiency. The transient wave erection Marx generator should be used where fast rise times are critical.

High-voltage, nanosecond pulse generators are quite common in biomedical electroporation (the process of pore formation in cell membranes due to the presence of an electric field), high-energy electron accelerators, as well as plasma material modification applications (Fig. 5).

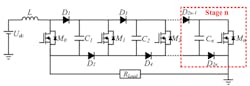

A boost-Marx pulse generator (BMPG) design is based on a traditional solid-state Marx pulse-forming circuit with the addition of chopper switch M0 (Fig. 6).5 The inductive element (L) is used for isolation in capacity storage and recovery. Users can adjust the inductor charging time to change the gain multiple of the pulse amplitude, reducing the requirement for the input dc voltage source. This reduces the number of circuit modules.

The circuit in Figure 6 not only has modular economical and reliable characteristics, but also leads to the circuit characteristics of miniaturization and high gain. Under the condition of an input DC voltage Udc of 500 V, this circuit can output 18-kV high-voltage pulses of 200 to 1200 ns. Also, the gain multiple of the pulse amplitude has reached 36 times.

Read more articles in the TechXchange: Power Supply Design.

References

1. “High-voltage technologies are key to empowering a more sustainable future,” Texas Instruments, 2023

2. “Performance Parameters Estimation of Pockels High-Voltage Sensors by Means of Numerical Optimization,” IEEE Transactions on Instrumentation and Measurement, Vol. 69, No. 4, April 2020.

3. Alex Pokryvailo, Costel Carp and Cliff Scapellati, “A 100 kW High Voltage Power Supply for Dual Energy Computer Tomography Applications,” Spellman High Voltage Electronics Corporation, IEEE 2014.

4. “Computed Tomography (CT),” National Institute of Biomedical Imaging and Bioengineering, 2022.

5. “A Novel Boost Marx Pulse Generator Based on Single-Driver Series-Connected SiC MOSFETs,” IEEE Transactions on Industrial Electronics, Vol. 71, No. 2, February 2023.

6. “Power Density Optimization of 700 kHz GaN-Based Auxiliary Power Module for Electric Vehicles,” IEEE Transactions on Industrial Electronics, Vol. 36, No. 5, May 2021.

7. “What’s Driving EVs to Higher Battery Voltages?,” Electronic Design, August 30, 2022.

8. “An Integrated Optics Sensor for High-Voltage Measurement Applications,” CCECE/CCGEI '93.