As electronic products have grown in complexity with highly evolved feature sets, system designers by necessity have developed correspondingly sophisticated schemes for load and power management. PCB-design intricacy, energy budgets, signal integrity, and, in some cases, thermal management issues have driven up the number of point-of-load (POL) buck regulators that typical systems use.

Related Articles

- Fundamentals Of Buck Converter Efficiency

- Improve Phase Margins In Buck Converter Loop Compensation

- Input Ripple-Current Balancing By Phase Shifting Multiple Outputs

Meanwhile, smaller, more sharply focused product design teams need to simplify design tasks that center on enabling functions, including power, and attend instead to those system attributes that best differentiate their products from those of their competitors. This need to simplify the POL-converter design-in process applies across virtually all product segments. In this context, one’s value assessment of POL integration options may differ from what it was, say, a decade ago.

Levels Of Integration

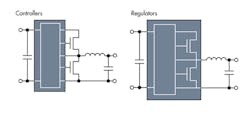

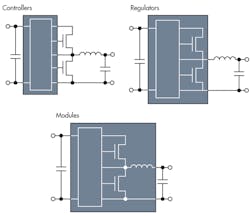

Commercially available buck converters are available in three varieties, distinguishable by their respective level of integration—controllers, regulators, and modules (see the figure). At first glance, the schematic distinctions between these three versions of buck converter appear rather inconsequential: a controller provides biphase gate drive to external power MOSFETs, which connect in turn to a two-pole LC filter. Regulators integrate the MOSFETs and leave the passive components outside the package. Modules bring the inductor inside the package and represent the highest degree of integration in power packaging of the three.

For most functions, a higher level of integration usually signifies monotonically greater value to a design, but in the case of buck converter components, the choice is not so automatic. Integration brings important engineering tradeoffs to buck POL implementations, the costs and benefits of which are not necessarily obvious or application independent.

Controllers, Regulators, And Modules

In terms of bill of materials (BOM) costs, controllers remain the least expensive option, modules the highest. Of the three, however, controllers exact the greatest engineering time and effort, impose the highest inventory management and assembly costs, and suffer the greatest exposure to supply chain interruption.

In the early years of switching power converters, operating speeds were limited to several tens of kilohertz. Power conversion efficiency expectations were still set with respect to what one could achieve with linear regulators, so performance in the low seventies of percent was welcome. In such an environment, the task of finding power MOSFETs compatible with a controller’s gate-drive outputs was not particularly onerous.

Today, however, converters typically operate at frequencies in the range of 0.5 to 4 MHz and efficiency expectations are in the nineties of percent. Here, requirements for waveform fidelity and timing accuracy in the gate drive signals are far more exacting. The gate drivers exhibit higher impedances than the MOSFET output, so careful control of device and layout parasitics on gate-drive lines is critical.

Engineers choosing controllers also must specify the output inductor. This can be a complex task because many factors affect inductor performance in the buck topology. I2R power loss due to the inductor coil’s equivalent series resistance (ESR) is a linear term at dc. The tradeoff here is component size versus power loss: larger components afford heavier gauge wire, and ESR decreases with the square of the wire’s cross-sectional radius. As operating frequencies have increased, the skin effect common to all conductors becomes apparent and the power loss increases nonlinearly for harmonics of the switching frequency.

Magnetic core properties also complicate inductor selection. Designers specifying inductors, particularly for highly efficient power channels, must calculate the core losses and ensure that the circuit doesn’t approach the component’s saturation flux under any of its operating conditions.

By integrating the switching devices into the package, regulators can minimize gate-drive lead lengths and, with them, their parasitic inductances. Having firsthand knowledge of the entire power train, the regulator manufacturer can determine the necessary inductor characteristics—saturation flux, B-H loop area, and the variations of electromagnetic properties over temperature—and recommend commercially available components that meet the full set of design criteria.

Though the historic origins of the controller explain its level of integration, at high frequency and high power density, the regulator represents a more natural instance of segmentation. The output switch-node impedance is low and drives an explicit inductor, so a small stray inductance from the interconnecting copper isn’t problematic. Even so, because the output line carries the full load current, designers specify a wide PCB trace to minimize trace resistance, which reduces the trace’s stray inductance as well.

An additional benefit of integrating the power MOSFETs into the converter package is that regulators tend to allow tighter PCB layouts than converters do. This isn’t only a matter of circuit board economics. Minimizing the physical area of the ac loop also helps reduce radio-frequency interference (RFI) emissions. This is an area of growing concern as the number of POL channels increases and, increasingly, applications must comply with emissions standards.

The next step in integration, modules, can aggravate the already substantial thermal design challenges to high-power-density designs. After the power MOSFETs, the inductor can be the next most dissipative component in a buck converter circuit. Bringing the inductor inside the converter package adds a significant heat source, limiting the converter’s operating temperature range. As a result, module makers often must impose power-derating curves that begin at a much lower temperature than for equivalent regulators. Derating curves starting at 35°C or lower are common.

For, say, a server application in which chassis interiors operate at 65°C, a module’s derating curve can impose a one-third penalty on output power, and that’s without the safety margin reliability requirements impose. Regulators with external inductors, though, often derate their output current for temperatures of 65°C and above.

Compensation also can complicate POL-converter implementation. Designers usually must calculate component values necessary to compensate controllers. Surprisingly, this also can be true of some regulators and modules. Having to determine the S-plane locations of the converter transfer function’s poles and zeros and calculating the compensating terms may not be an enjoyable task or practical use of time.

As mentioned, a buck regulation scheme with higher integration may not be the automatic choice. While higher integration from a controller provides clear benefits in parasitic reduction, full integration (or module use) may not provide a “complete” solution or one that can be easily implemented. Application requirements and thermal demands need to be reviewed to assess the best regulator or module to use.

Robert Gendron is the vice president of the Picor Business Unit at Vicor. He has an MBA from the University of New Hampshire Whittemore School of Business and Economics, an MSEE from Northeastern University, and a BSEE from Clarkson University. He also has a graduate certificate in management from Harvard University and completed the California Institute of Technology Program for Technology Marketing.