Battery energy density is a key performance metric for mobile handset manufacturers. It has a crucial influence on handset design and performance. Therefore, it has a huge impact on the user experience.

The mobile market faces continued pressure to reduce battery size and extend battery life as processing power increases, data rates rise, and handsets get even thinner. Although there has been some respite in recent years due to increasing screen sizes, battery size and weight are still a major consideration for phone designers, forcing them to consider newer power sources with higher energy densities.

Related Articles

- Envelope Tracking Now Essential To Achieve PA Linearity And Efficiency

- Software Supports Envelope Tracking For LTE Development

- Envelope Tracking Mitigates LTE RF Front-End Power Issues

Most recent handsets and portable devices have relied on lithium-ion (Li-ion) batteries, which have been successful in supporting a range of applications, including the ongoing early era of smart phones. But with the advent of 4G and ever-increasing application processor performance, Li-ion batteries are being pushed to the limits of their capabilities. A technology gap has opened between the energy required by mobile components and the capabilities of the batteries.

As a result, new battery chemistries such as lithium-sulphur are being developed to support the higher demands of the next generation of handsets. These new battery designs have a higher energy density, which helps extend battery life and enable more power to be packed into smaller, thinner handsets.

New Design Challenges

However, these battery chemistries introduce some new characteristics and new challenges for product designers to overcome. One key area impacted by these new chemistries is the RF front end, one of the most power-hungry parts of the phone. At a time when innovation and changes in the RF front end are rife, battery challenges add another layer of complexity.

The high energy density of emerging battery chemistries comes at a cost: typically lower end-of-life (terminal) voltages, a wider variation in battery voltage from “full” to “empty,” and higher internal resistances. These challenges have to be overcome before these batteries can be widely adopted in handsets.

The Terminal Voltage Problem

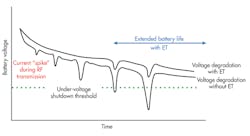

Li-ion batteries typically degrade at a steady rate from 4.2 V to 3.6 V, and then they rapidly discharge after 3.6 V. When 10% of battery life is remaining, Li-ion battery output voltage (“Vbat”) is typically still 3.6 V, ensuring full handset performance. New batteries with higher energy density, however, have a much steeper voltage degradation curve. When 10% of their battery life is remaining, the output voltage can drop as low as 2.5 V.

Due to the greater slope and reduced terminal voltages of the new high-energy-density batteries, handset components will have to be designed to work across a wider range of voltages to prevent performance suffering. It’s not an issue for the digital elements of the handset, where Moore’s law is driving lower digital supply voltages—2.5 V, 1.8 V, or even 1.2 V. Yet it does pose a problem for analog components such as the RF power amplifier (PA).

The RF PA is the final stage in the handset transmitter, which amplifies the signal from the modem chipset before connection to the antenna. RF PAs for cellular applications typically require a 3.4-V supply to deliver full output power. However, higher voltages are required to transmit 4G LTE, which have a higher peak-to-average-ratio than 3G, at full power.

RF PAs are also evolving from highly tuned narrowband devices that can only cover a single 3G or 4G frequency to tunable devices that cover a wide frequency range. This also tends to push up the ideal operating voltage as a consequence of the impedance transformation required in the broadband RF match.

The RF PA is connected either directly to the battery or to a “buck” dc-dc converter, which can provide a high efficiency regulated voltage to the PA but typically requires a minimum of 200-mV drop between the battery and the output, limiting the maximum output voltage to perhaps 3.1 V at low battery. New chemistry batteries may need the PA to operate as low as 2.3 V, though. The RF PA, then, cannot deliver sufficient transmit power to the antenna, resulting in call dropouts and reduced data rates.

ET To The Rescue

Envelope tracking (ET) technology, which already offers a range of benefits for the RF front end and is being widely adopted in 2014 smart-phone platforms, can help address these challenges. With an ET PA running at full power and a 4G waveform, the average voltage needed is typically only around 1.5 V to 2 V, with short peaks requiring up to 4.0 V to 4.5 V.

ET implementations come in two varieties. “Buck only” ET ICs are usually restricted to peak output voltages below the battery voltage, and “ac boost” ET ICs can deliver peak outputs above Vbat.

“Buck” ET solutions don’t help address the low voltage problem in portable devices, since the peak output voltage is still limited to below Vbat. But with some of today’s ac boost ET ICs, full RF output power can be maintained down to a battery voltage of 2.8 V or even 2.6 V. In this way, ET allows full performance to be maintained even with new battery chemistries and allows the full battery capacity to be used, without compromising on wireless coverage or system performance.

While a similar result could be achieved by connecting a separate boost dc-dc converter before the “buck-only” ET IC, this comes at the expense of efficiency. The additional boost converter will reduce efficiency by around 3% to 4%, even when the battery voltage is high enough not to need it.

High Internal Resistance

Another battery requirement with today’s complex mobile handsets is low internal resistance. Today’s bursty digital transmissions load the battery with short, heavy current spikes, which can easily reach 1.5 W to 2 W for Wi-Fi and LTE PAs when they are transmitting a burst.

The internal resistance of the battery results in a temporary but significant voltage drop at the battery terminal when this extra current is drawn, which can cause problems for other components in the system. Internal resistance generally rises as the battery charge is depleted, causing a greater and greater voltage drop during the bursts of high current. Finally, the voltage drop will trigger a “low battery”indication, forcing the handset to shut down, even though the battery may have significant charge capacity remaining.

To further complicate matters, the effect of low terminal voltages and high internal resistance is cumulative. As the terminal voltage of the new batteries decreases, the current demanded by the dc-dc converters will increase proportionately, leading to higher current spikes.

One of the main culprits in the peak current problem is the RF PA. With the improved efficiency of ET PAs, an ET-equipped system can reduce this peak current spike (and hence the voltage drop) by around 30%, significantly extending the useful life of the battery. This helps by ensuring that the maximum battery capacity can be utilized, even when internal resistance is high.

Innovating To Keep Up

ET is set to become a mainstream feature of mobile handsets from 2014, primarily as an energy efficiency and RF performance boosting technology. But it also gives phone designers other benefits to their power supply architecture, such as independence from battery supply voltage and reduced peak current spikes. These advantages can help enable the adoption of newer battery chemistries offering even higher energy densities than today’s Li-ion.