Power Semiconductor Makers Target New Products For Specific Applications

Today’s top semiconductor manufacturers have a new goal: goof-proofing their designs. The scale of these markets ranges from huge such as the Smart Grid to micro like energy harvesting. Even the makers of gallium-nitride (GaN) devices are devoting more effort to guaranteeing (to the extent that’s possible) first-pass success on new designs by tailoring parts performance to application-specific needs.

Texas Instruments

Last September, Texas Instruments introduced its bq

500212A transmitter, a next-generation wireless power transfer circuit designed to support the Wireless Power Consortium (WPC) 1.1 specification (Fig. 1). It reduces bill-of-materials (BOM) cost and implements foreign object detection. Essentially, a wireless charger that uses the TI device won’t power up unless it detects a device with a genuine WPC receiver in it.

Designed for Smart Grid developers, TI’s TMDSDC3359 smart data concentrator evaluation module (EVM) includes its own power-line communication (PLC) system. It comes with supporting software and facilitates the design of common families of data concentrators that can adapt to most worldwide Smart Grid standards. TI said the TMDSDC3359 lets developers set up a data concentrator demo with PLC connectivity in as little as 10 minutes.

On Halloween, TI’s bq27741 became the industry’s smallest pack-side battery fuel gauge with integrated protection against reverse connection. It comes in a 15-bump, 1.9- by 2.7- by 0.6-mm, 15-bump, chip-scale package (CSP). TI says that its Gauge Studio software supports the design of battery gauging. The company managed to squeeze the file size for the software by a factor of 10.

Four days later, TI announced the TPS92411, a 100-V, 2-Ω floating MOSFET switch for LED lighting applications. It lets designers build a flyback, buck, or boost converter with no coils or transformers.

Just after that, TI announced that it could supply all the components needed to create a complete sensorless motor control system for $66. They include the C2000 InstaSPIN-FOC (field-oriented-control) LaunchPad and the DRV8301 motor drive BoosterPack plug-in module. The combination embeds all the FOC software sensor algorithms in on-chip ROM, making it possible to design a three-phase synchronous or asynchronous motor controller in a matter of minutes.

At the same time, the company announced a compatible $49 “BoosterPack” plug-in module. The motor-drive DRV8301 simplifies the prototyping of low-voltage (6- to 24-V), medium-current (up to 14-A) motor controls to facilitate prototyping in anticipation of future higher-powered systems.

In November, TI announced five power management ICs for microwatt- to milliwatt-scale energy harvesting from light, heat, or mechanical sources. The bq25570, bq25505, TPS62740, TPS62737, and TPS62736 can power wireless sensor networks, monitoring systems, wearable medical devices, mobile accessories, and other applications with limited access to power.

The bq25570 is a boost charger with an integrated buck converter that consumes 488-nA quiescent current and operates at greater than 90% efficiency at output currents lower than 10 μA. It incorporates maximum power point tracking (MPPT) and supports rechargeable lithium-ion (Li-ion) and thin-film batteries, supercapacitors, or conventional capacitors.

The bq25505 boost charger is similar, but with an even lower active quiescent current (325 nA). An autonomous power multiplexor gate drive ensures that constant power is available whenever the system needs to operate, even when no energy is available from the harvester.

Linear Technology

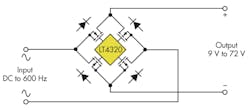

In June, Linear Technology announced a synchronous-switching controller that makes it possible to replace the diodes in a full-bridge rectifier with MOSFETs, eliminating losses from the forward drops of conventional silicon diodes. The LT4320 “ideal diode bridge controller” can work in 9- to 72-V systems and can switch from dc to 600 Hz (Fig. 2). It can handle power levels ranging from one to thousands of watts. The integrated charge pump that provides the gate drive for the external low on-resistance N-channel MOSFETs requires no external capacitors.

In October, the company introduced the LT4321, another ideal-bridge controller explicitly for Power over Ethernet (PoE) devices. IEEE 802.3 PoE specifications require power devices to accept dc supply voltages of any polarity over their Ethernet inputs. The power savings compared to diode bridges creates two advantages: they may enable powered devices to stay within lower PoE classification levels or they may allow designers to add additional functionality while maintaining the same class.

Announced in August, the LTC3330 regulating energy-harvesting chip decides whether the output of an energy harvesting system comes from the harvesting source, be it piezoelectric, solar, or magnetic, or from the battery. When energy is available from the energy-harvesting transducer, the LTC3330 delivers up to 50 mA of continuous output current to extend battery life when harvestable energy is available. When it is providing regulated power to the load from harvested energy, it requires no supply current from the battery and draws only 750 nA operating when it is powered from the battery under no-load conditions.

In November, Linear announced a versatile high-voltage power manager and multi-chemistry battery charger that can efficiently transfer power from a variety of sources to a system power supply rail and a battery. It is based on LTC’s intelligent PowerPath topology, which reduces the voltage range required by downstream system components to that of the expected battery voltage range, rather than the full extent of the input voltage source. Instant-on operation ensures the delivery of system load power with a fully discharged battery.

The LTC4020 operates across an input voltage range of 4.5 to 55 V. Output voltage can range up to 55 V. There are three selectable termination algorithms. The device features a step-up/step-down dc-dc controller, enabling operation with battery voltages that are above, below, or equal to the input voltage. Typical applications include portable industrial and medical equipment, solar-powered systems, military communications equipment, and 12- to 24-V embedded automotive systems.

Maxim Integrated

Announced last January, Maxim Integrated’s 78M6610+PSU/78M6610+LMU single-phase energy-measurement processor chips provide simple utility-grade sensing and diagnostics without the traditional cost of a utility meter system-on-chip (SoC). The 78M6610+PSU suits real-time monitoring of data centers, servers, and telecom and data equipment. The more general 78M6610+LMU fits white-good appliances, smart plugs, electric vehicle chargers, and solar inverters. What’s different here is that the 78M6610 processors do not require a separate microcontroller. Designers can add a complete energy meter to an already existing design without significant cost or redesign.

Last March, Maxim announced its MAX17050 high-accuracy battery fuel gauge (Fig. 3). Rather than coulomb counting, it uses the company’s ModelGauge m3 algorithm, which combines coulomb counting with Maxim’s voltage-based ModelGauge approach. Although coulomb counting is highly accurate at first, it tends to drift over time. ModelGauge m3 makes continuous micro-corrections and eliminates sudden jumps in a battery’s state of charge.

Announced last April for battery management, Maxim’s MAX14920/MAX14921 high-accuracy, 12/16-channel cell-measurement analog front ends (AFEs) double the accuracy of cell voltage readings through the use of high-accuracy common-mode level shifting and an integrated high-precision amplifier that simplifies analog-to-digital converter (ADC) data conversion.

Shortly thereafter, Maxim introduced the MAX77301, a Li+ battery charger that automatically identifies the adapter type and then determines the fastest rate to charge a battery. With advanced temperature monitoring, the MAX77301 modulates the charge current and battery regulation voltage automatically to maximize safety in any temperature environment. It performs all of these functions without an external CPU or system hardware. It’s intended for mobile equipment such as cameras, Bluetooth headsets, MP3 players, and portable medical devices.

Thanks to its long association with automatic teller machine (ATM) makers, Maxim Integrated has long been a leader in secure communications. Last June, it announced sampling on its DS28E35 DeepCover Secure Authenticator, a secure cryptographic device that lets a host controller authenticate peripherals.

The DS28E35 integrates a FIPS 186-based, Elliptic Curve Digital Signature Algorithm (ECDSA) engine to implement asymmetric (public-key) cryptography to operate a challenge-and-response authentication protocol between a host controller and attached peripherals, sensors, or modules. It operates over the 1-Wire single-pin interface to provide crypto-strong authentication security for applications such as medical sensors, industrial programmable logic controller (PLC) modules, and consumer devices.

Essentially, the DS28E35 eliminates the need for the host controller to store and protect the authentication key required for comparable symmetric (secret-key) solutions. It protects the private key it stores through Maxim’s DeepCover security technologies, which provide the strongest affordable protection against die-level attacks. DeepCover technologies include advanced die routing and layout techniques along with additional proprietary methods for private key protection and circuits that actively monitor for tampering.

In September, the company followed with its DS28C22 DeepCover Secure Authenticator, which supports the FIPS 180-based SHA-256 authentication algorithm. The DS28C22 combines crypto-strong, bidirectional, secure challenge-and-response authentication with small message encryption. Through bidirectional authentication, the host and the peripheral authenticate one another, protecting the intellectual property (IP) in the peripheral from a non-authentic host trying to modify operation of the peripheral.

Intersil

In April, Intersil introduced its ISL6730A active power factor controller with what the company called a breakthrough in negative capacitance technology (Fig. 4). With it, the capacitor can be moved from just ahead the bridge rectifier to the output side of bridge, allowing the use of a smaller capacitance value and reducing the size of the size of the electromagnetic interference (EMI) filter. It also makes it possible to use a smaller inductor.

Announced in December, Intersil’s ZL8800 point-of-load (PoL) regulator incorporates what the company calls a “ChargeMode” control loop technology that essentially eliminates control-loop compensation from the design process (see “Power Controller And Interface Transform POL Regulation” at electronicdesign.com). An advanced graphical user interface (GUI) that facilitates design-ins backs it up.

Fairchild

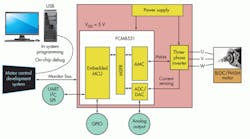

In March, Fairchild Semiconductor introduced the FCM8531 analog and digital integrated motor controller, a configurable hardware and software package that includes user guides, reference designs, and evaluation boards that help motor control (Fig. 5). This three-phase, hybrid brushless dc/permanent magnet synchronous motor (BLDC/PMSM) controller has two parallel processors: an advanced motor controller (AMC) and an embedded MCU on a chip.

The two core processors work independently but collaboratively to exchange data through an internal communications interface. The AMC performs algorithms such as sine wave control, FOC, and direct and quadrature (DQ) control, using Fairchild’s configurable libraries.

Also for motors, Fairchild added its SPM 5 smart power module series three-phase MOSFET inverter solution, giving designers an ac induction motor (ACIM) and BLDC motor inverter solution for motors up to 200 W, which generally includes fan motors, dishwasher pumps, and small industrial motors.

Introduced in November, Fairchild’s Smart Power Stage (SPS) module family integrates a MOSFET and driver for high-switching-frequency applications such as synchronous buck dc-dc converters in computing and telecom. As modules, control can be optimized for Fairchild’s high-performance PowerTrench MOSFET technology, eliminating the need for a snubber circuit in most buck converter applications.

Wide Band-Gap Power Devices

Turning from complex parts to power switching devices, GaN MOSFETs are becoming almost mainstream, but some companies are more active than others.

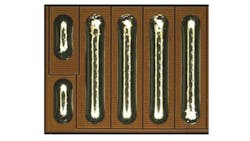

Announced in September, the Efficient Power Conversion (EPC) EPC2016 GaN MOSFET is rated for 100 VDS and 11 A, with a maximum RDS(on) of 16 mΩ with 5 V applied to the gate (Fig. 6). Compared to a state-of-the-art silicon power MOSFET with similar on-resistance, the EPC2016 is much smaller with switching performance that’s exponentially superior, according to the company. With Texas Instruments’ LM5113 GaNFET gate driver IC used in a half-bridge configuration, the EPC9010 development board allows evaluation of the devices. Meanwhile, the EPC2018 is a 150-V, 12-A device with a maximum on resistance (RDS(on)) of 25 mΩ.

Later in September, EPC introduced its third generation with the EPC8000 family, which is characterized by switching transition speeds in the sub-nanosecond range, making the devices capable of hard switching applications above 10 MHz. Yet the MOSFETs also exhibit very good small-signal RF performance with high gain well into the low-gigahertz range, making them a competitive choice for RF applications.

RDS(on) values range from 125 mΩ through 530 mΩ, and there are three blocking voltage capabilities: 40 V, 65 V, and 100 V. The family also offers lower QGD for lower-voltage transient switching losses. Its improved Miller ratio provides high dv/dt immunity. Its low-inductance pads improve the connection to both gate and drain circuits. The orthogonal current flow between the gate and drain circuits reduces common source inductance (CSI) reduction. A separate gate return connection also helps reduce CSI.

In May, International Rectifier said that it had qualified and shipped products built on its revolutionary GaN-based power device technology platform for a home theater system manufactured by a leading consumer electronics company, but it did not go into further detail. Meanwhile, In November, Transphorm a company that only emerged from stealth mode at APEC 2011, announced an agreement with Fujitsu Liimited and Fujitsu Semiconductor, whereby Fujitsu Semiconductor and Transphorm will integrate their gallium-nitride (GaN) power devices for power supplies businesses. Not that Transphorm is being swallowed: both Fujitsu Limited and Fujitsu Semiconductor will take a minority equity position in Transphorm, and the new Transphorm-Japan is a wholly-owned subsidiary of Transphorm, Inc. The Acquisition gives Transphorm a wider product base that will now include both low-and high-voltage GaN devices based on Fujitsu's 200-V enhancement-mode technology and on Transphorm's 600-V HEMT.