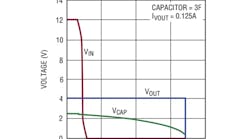

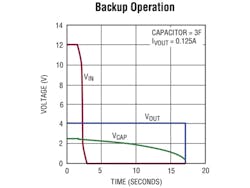

Last Month, Linear Technology introduced the LTC3355, which it calls a “complete, ride-through, dc/dc system IC.” Essentially it charges and regulates the output of a “small” ultracapacitor, in order to temporarily hold of the supply voltage for mission-critical circuitry until a data backup supply kicks in. Linear says there is considerable need for such a “ride-through “application and products such as power meters, industrial alarms, and the solid state drives. Stated more concretely, the LTC 3355’s nine, synchronous, constant-frequency, current-mode, monolithic-A buck switching regulator provides a 2.7 to 5-V- regulated output voltage from an input of supply up to 20 V.

I’m always interested in the chip design process, particularly for one-of-A-kind devices like this, so

Linear let me talk to Sam Nork who heads up the company’s Boston Design Group, where this part was created.

Don: “I guess the first question is, where did the idea come from, was here already anything like this around? Another is what aspects of the design were particularly interesting?”

Sam: Well, for the first question, the fundamental aim of this product was to integrate all of the necessary components to build a capacitor-based short-term backup circuit. This sort of alternative to battery backup is pretty common in things like power meters and alarms, industrial alarms, and data-backup. However, to my knowledge, there were previously no integrated circuit solutions like this available anywhere. Therefore the So the task on our part was to design a device that would provide all of the necessary functions to provide uninterrupted power for a short amount of time using energy stored in a capacitor.

“There were a few things that were interesting. For instance, the wide range of the main power source. That wasn’t a big challenge: we just made a buck regulator that that produces a regulated output from an input of 3 to 20 volts. The trickiest question we had to consider was response time. If V-in goes away in a nanosecond, you'd like, but you don’t want to accomplish that with a whole pile of capacitors out on V-out. ”

“That’s reasonably tricky. Of course, it can be solved with an external diode, but that's kind of clunky and inelegant. Also, you want to prevent the boost regulator from back driving V-in, if for instance, V-in gets shorted by a screwdriver to ground. In that case, you don't want your backup supply to get shorted also.

“ So we had to provide a blocking path from V-out back through the part, so that V-in doesn't simply load it. Those were the two of of trickiest problems that we had to solve with this part. After that, the rest of it was really just a mater of production of definition, providing all the kind of hooks and features that people, interested in these applications would want to have. For instance, in the case of power meters, there are limits as to how much power the meter can pull off of the mains, because it's usually the power company that pays for that, not the consumer.

“That makes it handy to have something like an input current limit. But that introduces a conundrum: you want to charge up your capacitor as fast as you can, but if you have a limit as to how much power you can pull, you have to be able to manage that. We decided to make all those features programmable external resistors.

Don: “How many man-hours, weeks, went into developing the part?

Sam: “Well, it's hard to say. There's a decent amount of work that just goes into figuring out, 'Okay what, exactly, do we want to build?' If we're a user of this part, what kind of features will make it useful for as many applications as we can possibly foresee. There’s a lot of effort that goes into that. Once we've got the definition, and we've chosen kind of a technology to use, and then we try, like always, to borrow as many existing building blocks as we can and figure out, If we have to invent something new, we'll invent something new, but the way to get the shortest development time is to use things that you already know work, so we try to do that as much as possible.

“But things like the two problems that I mentioned require brand new design, and it's hard to put an exact number on how long it takes. It takes months to verify a circuit design and then it takes months to complete a layout and then more months to fabricate it and more months to evaluate it. So these projects, they stretch out. Two years is pretty common, from start to finish.”

Don: “Anything to add?”

Sam: “It’s important to get the fundamental concept across to the system designer. This is not the same as battery-based backup circuit. In a battery-based system, the battery keeps things alive for a long time. In this case, it's a whole different animal. Because we're using a capacitor the amount of time that we can keep things alive is much shorter. So if it's data that the system has to save, that has to be done in a hurry. If it's some kind of alarm you have to sound, you've got a limited amount of time to do that. That affects how big of a capacitor you want to use.

Don: “So you don’t have the luxury of a battery, but you also don’t have the problems of a battery.”

Sam: “Right, you don't have the lifetime issues of the battery; you don't have all the safety concerns of the battery; you don't have all of the care and feeding. Batteries are finicky beasts, so it's nice to not have to deal with that.”