Though not fully mature as of yet, demand for lithium-ion battery technologies is higher than ever. In particular, the demand for harsh-environment-graded batteries is on the rise. For example, we’re seeing greater use of them in military and space applications, which typically have temperature ranges of between −40 to 80°C. Electric vehicles represent another popular application—battery systems must be able to perform well in both cold and hot conditions.

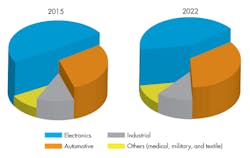

According to Allied Market Research (Fig. 1), electronics is the highest revenue-generating industry vertical for the Li-ion battery market, owing to the increase in their adoption in smartphones, tablets, laptops, and personal computers. However, as indicated above, the automotive segment is expected to be the most lucrative industry for these batteries, thanks to greater demand for electric vehicles and hybrid vehicles in China, the U.S., and Japan, among others.

1. In this chart comparing the global lithium-ion battery market in 2015 and what’s forecast for 2022, the electronics industry is the dominant consumer. (Courtesy of Allied Market Research)

Despite all of the advantages offered by Li-ion batteries, they suffer from aging and are prone to thermal runaway. Potential events similar to the Samsung Note7 and Boeing Dreamliner incidents are increasing the pressure to find better materials and designs for these batteries. Also, Li-ion performance drops as the temperature dips, due to the impact of the temperature on the mobility of electrons through the battery. Clearly, the technology still needs to mature.

Life Management

On this front, a team at Rice University is researching new ways to extend the life of lithium-ion batteries in extreme heat or cold temperatures. According to a published paper of their findings, they focused on the thermal tolerance of Li-ion batteries from a materials perspective in harsh environments. More specifically, they investigated how batteries perform in temperatures from −60 to 150°C (−76 to 302°F), knowing that current batteries are designed to operate near room temperature and within a narrow temperature range.

“Most research involving batteries and temperatures involve management systems. For instance, if a phone is used in cold temperatures, they slow it down a little bit to preserve the battery,” says Hemtej Gullapalli, a postdoctoral researcher at Rice and co-author of the paper. “But we found in our review that the perspective is changing slightly. To make batteries that work from low to high temperatures, scientists have to take the materials perspective to see what temperature is specifically doing to the materials.”

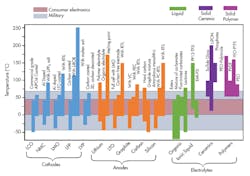

2. A map created by materials scientists at Rice University will help other labs develop lithium-ion batteries for extreme environments. (Courtesy of Rice University)

The paper reports on the prospective materials for each of the three basic battery components: negative anode, positive cathode, and conducting electrolyte. The authors of the paper emphasized how critical it is to understand the limits of the materials being used. They even built a comprehensive map (Fig. 2) of both standard and promising new materials in commercial batteries, and detailed the typical energy densities and temperature ranges for each component.

For example, water-based electrolytes like lead-acid and nickel-metal hydride operate only between −50 and 50°C, while molten salt batteries work fine only at temperatures above 90°C. Batteries with lithium thionyl chloride operate between −60 and 150°C, but only at peak between 20 and 55°C. To read more about their findings, click here.

Developments like those announced by Rice University directly impact the renewable-energy world, because batteries and renewable-energy technologies work efficiently together. As battery researchers overcome challenges through the study of better components (cathodes and anodes), materials, and improved power-management and cooling techniques, it will lead to batteries with larger capacity and faster charging capabilities.