Download this article in PDF format.

Next-generation systems, from industrial Internet of Things (IIoT), factory automation, defense electronics, and network infrastructure equipment to medical and consumer devices, all need to collect, synthesize, and act upon data. Sensors are widely used and have transformed electronic equipment with new intelligence. This new intelligence requires more power in ever-shrinking spaces without impacting the thermal budget, making conventional solutions unviable and complicated.

In the race to get to market quickly, designers have limited time to design the power supply and limited space to dissipate the heat while also meeting shock, vibration, and EMI requirements – a multidimensional challenge. High temperature rises and larger power supplies limit space and opportunities for more product innovation. How can designers power-shrink equipment footprints and sensors reliably without overheating? And how can they get it done quickly?

In this article, we'll discuss power supply design challenges and innovative solutions to get the extra space needed to support critical features and to save power supply design time.

Smart Sensor Market Trends

The fourth industrial revolution, commonly referred to as Industry 4.0, impacts the current trend of automation and data exchange in manufacturing where cyber-physical systems, the IIoT, cloud computing, and cognitive computing all operate together to create a “smart factory.” Within the smart factory structure, cyber-physical systems monitor physical processes. They communicate and cooperate with each other and with humans in real time and make decentralized decisions. To monitor physical processes with a higher level of intelligence, smart sensors are used.

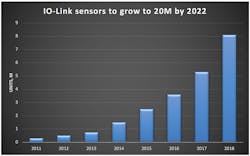

In 2018, approximately 70M sensors were being used in factory automation, and 8M (or 11%) of those are smart sensors with IO-Link technology. The market for smart sensors with IO-Link is expected to grow to 20M by 2022 (Fig. 1).1

1. IO-Link sensor market trend.1

Old-School Sensors Review

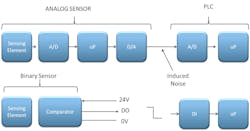

Historically, a sensor included a sensing element and some way to get the sensing data to the programmable logic controller (PLC) (Fig. 2). Data was often transferred in analog format and was unidirectional (sensor to master only). Analog data communication is prone to noise, and there is no way for the controller to diagnose, re-configure, or recalibrate the sensor directly.

2. “Old-school” analog and binary sensors.

These analog sensors worked, but as technology advanced, sensor manufacturers integrated more functionality into sensors, reducing noise susceptibility with the introduction of binary sensors. Binary sensors are governed by the IEC 60947-5-2 standard. But data is still limited to unidirectional communication from the sensor to the master, has no error control, and still requires a technician on the factory floor for tasks such as manual calibration.

Smart Sensors

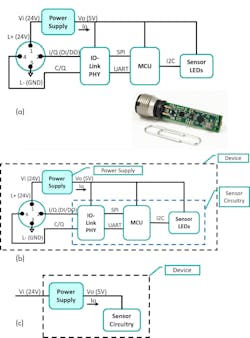

A better solution was needed to meet the demands of “Industry 4.0,” smart sensors, and reconfigurable factory floors. The solution is IO-Link (Fig. 3). IO-Link enables intelligence at the edge of the factory floor, allowing bi-directional communication between sensors and the controller. The system can adjust, configure, and diagnose sensors in real time.

3. PLC with IO-Link sensor.

A traditional factory is typically built and optimized for a single product. Once the product quota is met or if the market demand decreases, the factory sits idle. Reconfiguring this traditional factory to make another product requires additional time and money. A smart factory, on the other hand, enables efficient, on-the-fly reconfiguration to quickly adapt to market demand fluctuations. With real-time diagnostics, predictive maintenance is possible and factory uptime is maximized. All these benefits are possible now with IO-Link, smart sensors, and other technology advances mentioned earlier.

Smart Sensor Features and Design Challenges

Some main features of a smart sensor are: IO-Link compliance, full field configurability, real-time diagnostics, and small size (in order to be ubiquitous). Smart sensors should have intuitive programming to simplify their initial setup and help eliminate logic errors. They should be fully configurable to reduce device inventory and to support multiple profiles to facilitate flexible manufacturing.

So, what are the drawbacks? Those smart features increase power dissipation in sensors. At the same time, there is a surging trend toward miniaturization among various manufacturers. To power these wonderful sensors, designers face two big challenges: heat and size.

Design Example: Powering Miniaturized Smart Sensor

Let’s look at a smart proximity sensor with IO-Link. Figure 4a illustrates this sensor block diagram. The microcontroller (MCU) collects data from the sensing element, linearizes and calibrates it, and sends it to the IO-Link transceiver, where the data is then sent to the system PLC. The IO-Link connector also provides 24 V to power the sensor.

4. A smart proximity sensor with IO-Link (a); a smart proximity sensor with IO-Link (b); and a simplified block diagram (c).

To facilitate our power design discussion, let’s group all sensor elements into “sensor circuitry.” The “power supply” is the power solution used to convert 24 V to 5 V, which, in turns, powers our sensor circuitry. We’ll simply call the physical sensor the “device” (Figs. 4b and 4c).

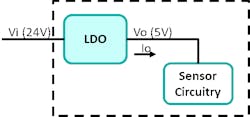

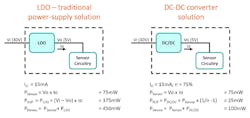

Let’s take a look at the power dissipation of the sensor circuitry, power supply, and total device using an LDO (low drop-out linear regulator), a traditional power solution (Fig. 5).

5. An LDO is a traditional power solution for sensors.

An old-school analog sensor circuitry typically consumes about 15 mA. The 24-V industrial power rail can reach 30 Vdc maximum. The power dissipations are:

IO = 15 mA, Vi = 30 V (maximum)

PSensor = Vo x Io = 75 mW

PSUP = PLDO = (Vi – Vo) x Io = 375 mW

PDevice = PSensor+ PLDO = 450 mW

In this example, only 75mW is used to do real work (powering the sensor circuitry), while 375mW is lost in the LDO due to its inefficiency. 450mW is the total power that our device must dissipate.

Now, as more features are added to make the sensor smarter, this demands more current, which will worsen the device’s power dissipation. For example, if the sensor circuitry current increases to 30mA, following a similar calculation as above: IO = 30 mA, PSensor = 150 mW, PSUP = 750 mW, and PDevice = 900 mW. 900 mW exceeds the power dissipation limit of most small proximity sensors.

HEAT—The Biggest Issue for Your Design

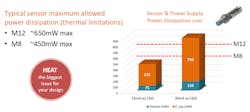

Heat is the biggest issue for your sensor design. Figure 6 shows power dissipation figures of the last two examples where LDO power dissipation dominates. The LDO’s excessive power dissipation limits how much current the sensor circuitry can have, thus inhibiting innovation. At 15-mA sensor current, the power dissipation barely fits within an M8 connector size, which has about a 450mW thermal dissipation limit. At 30-mA sensor current, not even a larger M12 can tolerate the heat dissipation.

6. Power dissipation vs. sensor thermal capability.

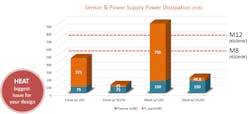

Clearly, we need to have a more efficient power solution to meet the thermal dissipation limit. Figure 7 shows a DC-DC converter solution. At 15-mA sensor current, and with a conservative 75% efficiency, the DC-DC converter has only 2 5mW of power loss and helps reduce the total device power loss from 450 mW to 100 mW, a 4.5x reduction in power dissipation.

7. Power-supply dissipation: LDO vs. DC-DC.

Repeating the same calculation for 30-mA sensor current, we can see that the high efficiency of the DC-DC converter reduces heat and enables more sensor current. This means we can pack more circuitry, features, and innovation into our sensor, making it smarter. Figure 8 illustrates this point.

8. High-efficiency DC-DC converter reduces heat and enables more sensor current/innovation.

SIZE—A Big Issue for Your Design

A smart system requires more smart sensors. Smart sensors must be small for use everywhere. Smart sensors also have more circuitry, yet must fit in increasingly smaller spaces. Figure 9 shows an M12 connector on the left, which has an outer diameter of 12 mm and a PCB maximum width of 10.5 mm. While this M12 connector can fit a typical DC-DC converter solution, a smaller size (M6) shown on the right has only a 4.5-mm PCB width. This small space is a real challenge as far as accommodating a power supply solution. Thanks to a recent advancement in integration, Maxim’s MAXM17532, with its tiny size of 2.6 x 3 x 1.5 mm, fits very well into this miniature sensor.

9. Size and your design.

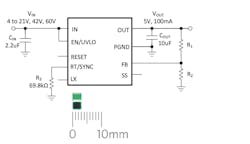

MAXM17532 is a 100-mA ultra-compact, wide-input-voltage uSLIC power module. It operates from 4.0- to 42-V input voltage. The output voltage is programmable from 0.9 to 5.5 V. Another part in the family, MAXM17552, can operate up to 60-V input voltage. Figure 10 shows the MAXM17532/MAXM17552 typical application circuit schematic.

10. MAXM17532/MAXM17552 typical application circuit schematic.

Summary

Industry 4.0 drives demand for smart sensors. Smart sensors require higher power, even given their shrinking size. Traditional power solutions using LDOs have excessive dissipation, creating heat problems. Sensor designers face two big challenges in terms of heat and size. To solve these challenges, the power solution must be highly efficient and miniaturized. Thanks to advancements in modern DC-DC converter integration, a highly integrated DC-DC power module provides the perfect solution.

Anthony T. Huynh is Principal Member of the Technical Staff, Applications, Industrial Power at Maxim Integrated.

Reference