Power-Supply Architecture Fuses Digital and Analog Control

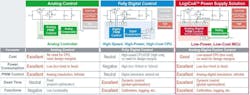

The digital control of switching power supplies is firmly established in everything from EV onboard chargers (OBCs) to power-supply units (PSUs) in AI data centers to renewable-energy systems that output up to tens of thousands of watts. Digital control is favored for its ability to enable precise control and settings. But beyond high-end power-supply circuits and DC-DC converters requiring very fast response times, high-performance MCUs and other digital power controllers remain a relatively rare sight due to their higher power and costs.

While analog control is commonly used in consumer and industrial power supplies from tens to hundreds of watts, it can have difficulty providing the high level of reliability and fine control required by modern systems.

ROHM Semiconductor is trying to bridge the gap between analog and digital control with its LogiCoA power-supply technology. The company calls it the first “analog-digital fusion control” architecture for power supplies ranging from 30 W up to 1 kW. ROHM also plans to roll out a family of LogiCoA MCUs that can deliver the same functionality as fully digital control for about the same power and cost as analog control technologies.

As Kenichi Morioka, technical product marketing manager at ROHM, pointed out, “The key advantage is that it provides the benefits of digital control at reduced complexity and power [and] at a more affordable price.”

The Differences Between Digital and Analog Power Control

In a digital power supply, the digital controller must be able to accurately measure current, voltage, and other output characteristics and then compare them to reference values. The MCU uses the feedback to determine the optimal pulse-width-modulation (PWM) waveform to control the switching of the power FETs—and then deliver the desired output. The MCU must be able to carry out these computations fast so that the power control algorithms can react to changing load conditions or even environmental conditions, said Morioka.

>>Check out this TechXchange for similar articles and videos

To stay a step ahead, semiconductor companies are rolling out real-time MCUs that merge high-performance CPU cores clocking at more than 100 MHz paired with digital signal processing (DSP) and other hardware accelerators for faster execution of more advanced power-control algorithms. They also include tightly integrated interfaces to current, voltage, or other sensors, along with high-precision analog-to-digital converters (ADCs).

In addition, high-resolution timers deliver tighter control of the PWM signals that determine the duty cycle, dead time, switching speeds, and other characteristics of the MOSFETs or other transistors at the heart of the power supply.

The core advantage of digital control is its flexibility. The approach gives you the ability to adjust the switching frequency or even the voltage and current values by updating the power supply's software. Digital controllers can also help bring fault detection, circuit protection, and many other features that are difficult to work out with analog control. One of the key tradeoffs involves the complexity of managing everything in software, although most companies are rolling out a rich ecosystem of development tools to assist with digital power.

These MCUs are hitting higher clock frequencies to keep up with the faster switching speeds of silicon-carbide (SiC) and gallium-nitride (GaN) power FETs without causing unnecessary delays, errors, or noise in the control loop. The flexibility of digital control is on full display in the latest power-factor-correction (PFC) and DC-DC converter stages in high-end switching power supplies, where it is used to maximize power efficiency as well as reliability.

But there are other drawbacks to digital control. Even though the costs are coming down, high-performance CPUs and other digital controllers cost a premium compared to more traditional analog controllers, said Morioka.

Digital control is also comparatively power-hungry. However, said Morioka, it rarely makes much difference in, for instance, data-center power supplies that are feeding several thousand to tens of thousands of watts to AI processors.

But add a digital controller to a DC-DC converter or power supply that handles more moderate amounts of power, and it can cut into the system’s overall efficiency. In power supplies ranging from tens of watts up to 1 kW, it makes more sense to use analog controllers to output the PWM signals, analog compensators to smooth out any undesirable fluctuations in the control loop, and other building blocks such as linear regulators. The analog control of power supplies is favored for its reliability and robustness, said Morioka. The technology can deliver fast response times and high stability due to its continuous analog feedback.

While they avoid the cost, power, and complexities associated with digital control, analog controllers tend to have trouble operating efficiently across different load conditions and input voltages, the company said.

“Since these components have fixed characteristics,” explained Morioka, “it's difficult to have the flexibility to adjust the output voltage settings or change the PWM timing based on the power supply's load conditions.”

The LogiCoA MCU: The Digital Power Control Block

ROHM rolled out its LogiCoA power-supply architecture to leverage the strengths of both analog and digital control. These hybrid power supplies are facilitated by a family of high-performance, low-power LogiCoA MCUs.

The LogiCoA MCU serves as the digital control center of the unique power supply paired with a separate analog compensator comprised of silicon MOSFETs and various analog and power devices, including op amps and current sensors. Morioka noted that “the feedback control, which typically requires intense computations in digital control systems, is handled using the analog compensator and the analog comparator in the MCU.”

In the case of a DC-DC converter, the control loop can be characterized by the frequency response. The frequency response influences the switching regulator’s precision, stability, and reaction time to transients and, in turn, how closely it keeps to a set output voltage under variations in the input voltage, load, and duty cycle. Whether assembled out of analog devices or implemented in the digital controller, the compensator adjusts the control-loop bandwidth and tailors the frequency response, and determines how well the power supply works.

The LogiCoA MCU stands out since it lacks the real-time performance of the 32-bit MCUs and other digital controllers on the market. The MCU is based on a 16-bit RISC CPU with a maximum clock frequency of 16 MHz and 32 kB of code storage, 4 kB of data storage, and 2 kB of RAM. The MCU features many of the same analog building blocks as other real-time processors for power control. These include a high-resolution 16-bit PWM controller with six channels and up to 13 outputs operating at a maximum speed of 64 MHz.

The timer is paired with a three-channel analog comparator with synchronous clock operation and response times up to 100 ns. The MCU also features a 12-bit ADC, 8-bit DAC, and single-channel programmable gain amp.

But the most important building block in LogiCoA is the PWM controller. According to Morioka, “The PWM controller can dramatically and dynamically adjust the power switch based on signals from the comparator in the MCU. As a result, switching operations can be performed independently of the CPU, making it possible to use a less powerful CPU while reducing costs. This also makes it adaptable to a wide range of power-supply topologies.”

RMOS: ROHM’s New Real-Time OS for Power-Supply Control

ROHM said LogiCoA reduces the tradeoffs between analog and digital control. It allows for the correction of performance variations in peripheral components, according to the power-supply circuit, by storing various settings such as current and voltage values in the MCU. Unlike more traditional power supplies, there’s no need to consider design margins, contributing to more compact power supplies that have higher reliability.

Morioka added the LogiCoA MCU can also record operation log data in its nonvolatile memory. ROHM said this is ideal for power supplies in industrial systems that require data logging as a backup in case of malfunction.

With software playing such a critical role in fully digital switching power supplies, ROHM unveiled a real-time operating system called RMOS for developing software to run on the LogiCoA MCUs. The company said it can help engineers take advantage of all the MCU’s features, including the PWM, ADC, and many other building blocks. Unless the software in the power supply is carefully designed, it can take longer to execute the intense computations at the heart of digital control, which can compromise real-time control, said ROHM.

According to the company, it implements the core functions of switching power-supply control. It also enables several types of switching power-supply circuits (for instance, PFC and DC-DC converter stages) to be controlled by a single LogiCoA and monitor the state of a power-supply circuit. To reduce the difficulties of digital power, it uses assembly language to develop power control programs in a modular way. “This will allow customers to focus on breaking down necessary processes into tasks without worrying about the real-time processing,” said Morioka.

Since not all power engineers have experience with digital control, ROHM also rolled out a power-supply reference design based on the LogiCoA MCU, enabling them to evaluate the concept of analog-digital fusion control in DC-DC converter circuits. The optional LogiCoA001-EVK-001 reference board and the example software that runs on top of it makes it possible to test and confirm the sequence control of execution tasks.

“It will take some time for engineers to fully grasp the control method, but once they figure it out, we believe developing power supplies and making customizations will go significantly faster than before,” said Morioka.

Some of the biggest impacts in power electronics stem from advances in power FETs. But he said that new innovations in software are going to play a bigger role in improving power supply’s performance in the future.

“Innovations in power devices such as GaN and SiC are crucial for improving power density,” said Morioka. “But it's equally important to have drivers and controllers that can fully tap into the capabilities of those devices. Additionally, safety and diagnostics features are essential for digital power control. LogiCoA stands out because it can flexibly adapt to these innovations through software, eliminating the need for constant development of new MCUs.”