SiC MOSFETs Tackle Tough Conditions in High-Power Electronics

Compared to traditional silicon, power MOSFETs based on silicon carbide (SiC) can handle higher voltages with lower on-resistance (RDS(on)) and superior thermal conductivity, opening the door to higher switching speeds. As these power electronics gain ground in everything from electric-vehicle (EV) power inverters and fast chargers to renewable-energy storage systems and power-supply units (PSUs) in data centers, power companies are racing to roll out advanced power MOSFETs that can draw out more of the power-handling properties of SiC.

On that front, Wolfspeed introduced its latest generation of SiC power MOSFET technology, which is all about improving the efficiency, reliability, and durability of SiC MOSFETs in high-power designs. The company said it upgraded the underlying architecture to reduce both the switching and conduction losses of the Gen 4 MOSFETs over a wide range of load conditions, enabling them to run at higher frequencies without creating as much heat. According to Wolfspeed, it translates to longer driving ranges for EVs and reduced cooling costs in data centers.

Said Jay Cameron, Wolfspeed’s senior vice president of power products, “Gen 4 enables design engineers to create more efficient, longer-lasting systems that perform well in tough operating environments at a better overall system cost.”

Gen 4 SiC MOSFETs: Limiting Power Losses at High Power Levels

Reducing conduction losses is all-important in power electronics, said VP of power technology development Adam Barkley. These losses, largely driven by the RDS(on) of the power MOSFET, vary depending on the load current and operating temperature of the device. One of the advantages of SiC MOSFETs over the silicon IGBTs that have dominated for decades is that RDS(on) is more stable over temperature.

Wolfspeed said Gen 4 benefits from a more than 20% reduction in RDS(on) when operating close to or at its maximum rated operating temperature. It reduces conduction losses in “real-world” conditions compared to its Gen 3 products.

The power electronics in EVs operate at relatively light loads most of the time. But when handling higher loads, SiC MOSFETs can come close to their maximum rated operating temperature. By diminishing the RDS(on) in these conditions, Gen 4 can operate more efficiently, which results in a longer lifetime for the system. Even at light loads, where currents and temperatures are lower, reductions in the RDS(on) over temperature directly translate into better power efficiency and system reliability, said Barkley.

>>Check out these TechXchanges for similar articles and videos

This gives a boost to soft-switching power electronics, such as high-frequency DC-DC converters used in onboard chargers (OBCs) and PSUs in data centers. Soft switching mitigates the power losses that come about during turn-on and turn-off of the power FET. Thus, the remaining power losses are dominated by conduction losses. For instance, the active power-factor-correction (PFC) stage at the front of a server power supply tends to use hard switching before it moves to a soft-switched DC-DC converter stage.

While these DC-DC converters are based on LLC or other power topologies where switching losses are less critical, the power MOSFETs inside them must still be able to handle the high current and voltage transients that present challenges in high-power designs.

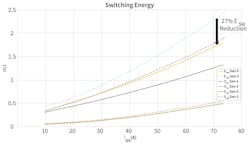

In EV traction inverters and other hard-switching power electronics, Wolfspeed said the Gen 4 technology also delivers a 15% reduction in switching losses during the MOSFET’s turn-on (Eon) and turn-off (Eoff) phases.

Barkley said the company made several improvements to the body diode inside the power device, significantly reducing the reverse-recovery losses that can be prevalent during switching. Reverse recovery occurs when the diode conducts current in reverse for a short time during the switching process. Due to the relatively large currents present during the turn-off phase—called reverse-recovery charge (Qrr)—and the relatively long time it takes for the stored charge to be removed from the MOSFET—reverse-recovery time (Trr)—the power losses can add up.

Compared to silicon, SiC MOSFETs have less Qrr and shorter Trr, leading to lower switching losses, noise, and heat. By losing less power to heat, the MOSFET can run more efficiently and safely at higher frequencies. Faster switching means engineers can use smaller and lighter magnetics and passives components, as well as smaller heat sinks. That helps reduce the area, weight, and cost of the system without sacrificing efficiency.

The company said the power MOSFETs are designed to do reverse recovery not only as fast as possible, but also as soft as possible, primarily to reduce electromagnetic interference (EMI) and other electrical noise in the system.

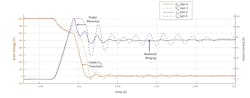

When the Qrr is rapidly removed from the power device, it can cause sudden spikes in voltage—or voltage overshoot, in the parlance of power electronics—which can be damaging to the power device and overall system.

Call it a “hard” landing for the power switch. The voltage can cause ringing, which may increase EMI and other noise in the system. This makes a big difference in high-frequency power electronics, said Barkley, where the faster switching transitions can lead to rapid changes in current (di/dt). These transients could bring about sudden leaps in voltage (dv/dt), which is what causes ringing in the switching waveform of the device. The noise can complicate EMI compliance and removing it from the system may require large, costly EMI filters.

Barkley said the Gen 4 MOSFETs have 75% less voltage overshoot during switching operations, increasing the reliability and robustness of the power system. This improvement helps reduce ringing and EMI.

Required for High-Power Electronics: Robustness and Reliability

Wolfspeed stated that its Gen 4 technology is also more robust, durable, and reliable than the previous generation.

The SiC power MOSFETs can tolerate temperatures of up to 185°C with limited life operation at 200°C. The power device’s operating temperature can increase sharply when overwhelmed by large voltages or overloaded by large currents. Barkley said the Gen 4 technology features 2-μs short-circuit withstand time, giving it the ability to shut down safely during faults and enabling compatibility with existing gate-drive ICs.

The SiC power MOSFETs are more robust against cosmic radiation and other environmental conditions, with improvements of up to 100x in the cosmic ray failure-in-time (FIT) rate compared to the prior generation, said Barkley.

The Gen 4 products also come with more advanced packaging, which is specifically designed for the high switching speeds and thermal performance of SiC. The packaging minimizes parasitic inductance in power, gate, and common-source loops, increasing the power density. The double-sided cooling design reinforces durability under rigorous conditions such as power and temperature cycling. The copper clip interconnects and internal busbars that Wolfspeed puts into power modules help ensure smoother, safer switching operations.

The Gen 4 family of chips comes with voltage ratings of 750, 1200, or 2300 V. The company said it will also put them into power modules and sell the unpackaged dies to anyone who wants to do that themselves.

Wolfspeed plans to expand its offerings with different RDS(on) characteristics through 2025 and into 2026.