Batteries fuel energy efficient technology

ResourcesA123 Systems Inc.,www.a123systems.com |

Batteries for EVs get a lot of headlines. But behind the scenes, better chemistries are letting battery makers squeeze more energy into pint-sized packages that are safer and work longer, and last longer than what’s available today. The most promising of these are based on lithium metal, zinc, and metal hydride electrodes.

The problem is, though, that advanced battery chemistries can get confusing. Not all of them are destined to find their way into devices the size of a coin cell. Each chemistry has its niche.

A lot of new chemistries aim to increase battery life. But what’s acceptable as a battery life is largely in the eyes of the beholder. As Sol Jacobs, vice president and general manager of Tadiran Batteries puts it, acceptable battery life is often dictated by application-specific requirements, because product designs must continually adapt to address customer needs as well as keep pace with the competition.

“As a general rule, short-lived batteries can suffice in situations where the product is easily accessible and the costs associated with battery failure are fairly minimal. However, if the device performs a mission- or safety-critical function in a remote location where battery replacement is impossible or not cost effective, then a long-life battery is a must,” he adds. Kohler, the faucet manufacturer, recently asked Tadiran to design a battery system lasting 30 years. The system goes into situations where there is no easy way to replace or recharge batteries, as in public bathrooms.

Tadiran makes the largest range of lithium thionyl chloride batteries on the market. These primary batteries have been proven to last over 25 years in the field. Their claim to fame is an incredibly high energy density level, the highest of all lithium types, combined with an extremely low discharge rate of less than 1% annually. These batteries are widely used for powering devices in the Smart Grid advanced metering infrastructure (AMI).

The principle primary (non-rechargeable) battery chemistries include alkaline, lithium manganese, lithium sulfur, and lithium thionyl. Alkalines continue to be widely used for powering consumer electronic items and come in a variety of sizes.

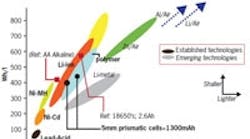

Major re-chargeable types include sealed lead acid, nickel cadmium, nickel metal hydride, lithium-ion, and lithium polymer to name a few. Nickel metal hydrides are fast replacing sealed lead acid batteries in many applications as a cost-effective transition toward lithium ion.

It looks as though other battery chemistries are ready to compete with rechargeable nickel cadmium, nickel metal hydride and lithium ion batteries. The primary application area for these technologies is in small batteries for consumer electronics, laptop/notebook computers, power tools, and some military applications. One chemistry in particular that looks promising is nickel zinc from PowerGenix Inc. Another is silver zinc from ZPower Inc.

Continue on next page

A primary (non-rechargeable) battery chemistry worth noting is zinc air, from Electric Fuel Corp. None of these has seen any mass-market application -- yet. Their claim to fame is a higher cell voltage (and thus a higher energy and power density) and greener chemistry. But they suffer from too few charge/discharge cycles, shorter lifetimes, and doubts about the economics of their manufacturing process.

AER Energy Resources recently worked on a rechargeable zinc air battery using what it calls a “diffusion air” principle. It has since licensed the technology to Duracell.

Even the venerable sealed lead acid battery, mainly used in automobiles, is benefiting from technological advances. For example, Panasonic Industrial Co. recently developed a series of improved rechargeable batteries specifically designed for backup power to wind turbines.

These valve-regulated lead-acid (VRLA) batteries do not require the addition of water for maintenance. They employ advanced micro-porous absorbed glassmat separators with calcium grids and a one-way resealable valve made of neoprene. When the battery generates gas because of extreme over-charge conditions, charger malfunctions or other abnormalities, the vent valve opens to keep pressure within a specific range of 7.1 to 43.6 kPa, protecting the battery from bursting.

Just one example of how far lithium ion battery technology has come is the use of a 2.5-kWh energy storage system from Boston Power Inc. The BPI system has been selected by the National Aeronautics and Space Administration (NASA) as part of Project M (for the Roman numeral M representing 1,000), a proposed project to land an operational humanoid robot on the moon in 1,000 days. The energy system makes use of high-performance Swing lithium ion batteries originally devised for electric vehicles and utility energy storage. Boston Power also makes high-performance Sonata lithium ion batteries.

Wireless sensor networks

Improvements in battery technology are helping to spread the use of wireless sensor networks, particularly in infrastructure, industrial, and building automation applications. Tadiran’s Sol Jacobs says that, “Many people are used to sensors that have wireless communications capabilities, but they are not aware that they can also cut the power cord by using batteries and save about $100 per foot of otherwise-installed power cables. In this way, they can have a truly wireless solution.”

For the moment, though, many wireless sensor configurations are bulky, need a lot of power, and cannot always withstand the rigorous environments of industrial and building automation settings. Nevertheless, the field is advancing, with wireless sensor networks finding use in applications ranging from RFID electronic toll tags in cars to asset tracking and automated meter reading (AMR) in the advanced metering infrastructure. In AMR, utility meters monitor and report on energy and water consumption in homes, offices, and buildings.

And a recent study by Oak Ridge National Laboratory shows how important battery technology is for wireless sensing. It outlined a dozen criteria for the Ideal Wireless Sensor points with the top two being adequate battery life and the need to be selfpowered and small.

Size is an issue for many wireless sensors. There’s only so much energy a small wireless sensor battery can store and deliver. Battery capacity in such applications is often influenced by the operating environment of the sensor, safety and regulatory requirements, the manner of energy delivery, battery maintenance and overall budget.

Continue on next page

Two of the most important battery selection issues are the ambient temperature and the charge/discharge rates the battery will see. Generally, the colder the temperature, the more energy a battery can store. But cold batteries do not deliver energy well until they warm up. Moreover, higher temperatures in a rugged environment can also drastically shorten battery life.

In addition, battery charge and discharge qualities differ depending on battery chemistries. In general, battery energy capacity is a non-linear function of current draw. High current drains reduce battery energy capacity.

There are safety and regulatory requirements involved in battery type selection. Ever-more-stringent environmental regulations make the use of certain battery chemistries undesirable. Safety standards are also an issue in that they dictate protection against battery explosions and overheating leading to fires, as well limiting a battery chemistry’s toxicity to the environment.

Of course, it is important for wireless sensor nodes to operate for as long as possible without a battery change. One means to that end is by employing energy scavenging transducers that charge up the battery. (See “Sensors Get a New Role as Energy Scavengers,” EE&T, July-Aug. 2010) The other way to maximize battery life is to simply turn off wireless sensor circuits when they aren’t doing useful work. Says Cees Links, founder and CEO of GreanPeak Technologies, a manufacturer of innovative ultra-low-power wireless and battery-free data communication controller chips: “The standard wireless network solutions only solve a wiring problem in sensor applications, making networks easy to install. However, ultra-low-power network solutions can also address the maintenance problem inherent to networks with a high number of nodes and a limited battery life. For example, a network with 4,000 nodes and a battery life of 10 years means that on average one battery per day must be changed.”

Low-power wireless protocols like ZigBee can be helpful in this effort by allowing multiple sensor operating modes like “sleep” and “standby” that minimize power consumption.

Carbon nanotubes

Carbon nanotubes (CNTs) are poised to make their mark in better battery chemistries. At the Massachusetts Institute of Technology (MIT), researchers are investigating the use of CNTs for battery electrodes that can last thousands of cycles without any loss in performance. Such batteries can power large vans or trucks, for example, yet be light enough and small enough to be practical for widespread deployment in more portable uses. Researchers say they are trying to make the CNTs thicker which would facilitate their use in a wider range of applications.

MIT researchers are also investigating rechargeable lithium air batteries, similar in principle to lithium-ion, but with one of the electrodes replaced by a carbon-based structure and a flow of air which, researchers say, can lead to higher energy densities. This technology has attracted a large amount of government funding and interest from such companies as IBM. Theoretically, such battery chemistries could store three times as much energy as conventional lithium ion batteries.

However, there are a number of technical challenges facing the commercialization of lithium air batteries. One major one is the vulnerability of its active materials to moisture (the lithium metal it uses can catch fire if it gets wet). Another is the tendency for such batteries to stop working after being recharged just a few times.

A123 Systems Inc. is a developer and manufacturer of advanced proprietary Nanophase lithium-ion batteries developed at MIT. They’re being used for transportation, electric-grid and commercial applications. Most recently, the company delivered 44 MW of A123’s Smart Grid Stabilization System (SGSS) to AES Power Co. for various new projects, including energy storage in Johnson City, NY.

There are other companies involved with developing nanobased lithium-chemistry batteries. These include Electrovaya, K2 Energy Solutions, and Altair Nanotechnologies, among many others.

The next big thing in battery technology is battery storage using immense capacitors also known as super-capacitors and ultra-capacitors (see related article on this subject in this issue). Having large energy storage levels that can work with high-energy density batteries like lithium ion types can go a long way toward improving battery usages for such things as wireless sensor networks.

Continue on next page

Such capacitors, though, do not have the energy density levels of lithium-based chemistries. The most modern supercapacitors generally have energy density levels of about 30 Wh/kg, a far cry from the 250-300 Wh/kg levels for lithium-based chemistries.

However, commercially available super- capacitors still can play an important role in battery powered devices. For example, MicroGen Systems LLC, a spin-off making use of research at the Cornell University NanoScale Science and Technology Facility has developed what’s called Bolt 120 power chip and cubes and ultra-capacitors. These items are said to eliminate or extend the life of lithium batteries six-fold in wireless sensor network applications as well as significantly reduce the cost to deploy and maintain such networks, according to initial field applications.

In the same vein, Tadiran Batteries makes a product called the PulsesPlus which combines the long life of a lithium thionyl chloride cell with the ability to put out a pulse rate like that of an HLC (Hybrid Layer Capacitor). This HLC has been specifically developed to work with Tadiran’s primary cell. ”Other super capacitors on the market have high self discharge rates and need component balancing. The HLC does not,” says Tadiran’s Sol Jacobs.

Another development in this area is a new composite patented by the Imperial College of London. It has both structural and functional uses. Made of carbon fibers and a polymer resin, it can store and release energy much more quickly than traditional batteries. Working with several European companies including car maker Volvo, the Imperial College of London is focusing its effort on developing a super-capacitor type material that can function as a car’s body panels as well as supply energy to the vehicle. The project is part of a multi-million-dollar three-year effort funded by the European Union. (See “Composite material does double duty as auto body panel, battery,” EE&T, July-Aug. 2010)

If the Imperial College of London gets industry pumped up about its body-panel batteries, vehicle occupants may find themselves literally riding inside a battery. But things may not stop there. People could end up wearing batteries as well. At this year’s most recent meeting of the American Chemical Society, MIT’s Mark Allen reported using a common virus, M13 bactriophage, to develop improved materials for high-performance rechargeable lithium ion batteries. The batteries could be fashioned into clothing to power portable electronic devices. “These new power sources could in the future be woven into fabrics such as uniforms and poured or sprayed into containers of any size and shape,” he says. These conformable batteries could power smart cell phones, GPS units, PDAs, and other smart consumer devices, as well as military unmanned aerial vehicles (UAVs).