Intelligent Energy Optimization System Slashes Electric Bills

Engineers at Power Metrics International (PMI) looked at age-old problems with a new perspective when they devised a patent-pending optimization technique for electric power management. The result was PMI’s SP1000A series of hybrid energy management and correction system that addresses inefficiencies in power delivery and usage. It guarantees and quantifies kilowatt-hour savings by reducing losses in power delivery, identifying and reducing harmonics, correcting for system imbalance, increasing equipment efficiency, and optimizing power utilization. Reductions in kilowatt-hours of 3% to 7% have been regularly observed. Total electric bill reductions of 8% to 15% have been achieved. User return on investment (ROI) typically ranges from 15 months to two years.

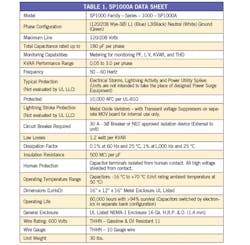

The SP1000A continuously measures current, harmonics, load-source imbalances, and power factor at a rate of 128 samples per cycle, then corrects for these parameters “on the fly.” It also stores data in five-minute increments for more than 15 months. It was designed and tested by PMI and manufactured by MHT, which produces high-efficiency lighting products. Table 1 lists the SP1000A data sheet

The circuit board of the SP1000A uses a conventional off-the-shelf triac and state-of-the-art, proprietary, long-life switches (rated for on and off switching times of millions before burnout like other types do), as well as small capacitors (Fig. 1).

Fig. 1. The SP1000 hybrid energy management and correction system board (top) and its capacitors (bottom) fit in an electrical subpanel. The system takes up little space yet saves a lot on electric bills.

It dissipates one-tenth the power of similar products during switching. The hybrid system is available in three versions:

208-V SP1000A (10 kVAR)

208-V SP1000B (17 kVAR)

480-V SP1000E (30 kVAR)

SENSOR PERFECT INTERFACE DATA EXCHANGE ROUTINES

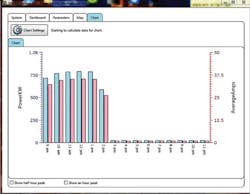

The system’s SPIDER (Sensor Perfect Interface Data Exchange Routines) software supports constant power-consumption monitoring and management. It gives users a “dashboard” view of readings in real time in charts. Also, it highlights issues like motor deterioration, allowing users to be proactive instead of reactive in their maintenance (Fig. 2).

Fig. 2. An hourly view of the SP1000 hybrid energy management and correction system provides a view of how a facility’s current levels (red) correspond with the power consumed in kilowatts (blue).

The system makes thousands of decisions per minute, based on what it is reading through external and internal current transmitters. It addresses harmonics, voltage imbalance, temperature rise and fall, loss of current, and other facility issues while increasing motor efficiency and reducing the operating temperature.

Underwriters Laboratories (UL) has approved the SP1000A system under Section 508. According to PMI executive vice president Robert Turner, it is the only system on the market that can monitor, record, and quantify true kilowatt/kilowatt-hour savings at this price point. For more information on UL requirements, see the box “UL 508- Industrial Control Equipment”.

The SP1000A also monitors each leg of a three-phase panel independently from the other two legs and then applies capacitance to each leg based on the load characteristics and arbitration between all governing parameters, according to the system’s inventor Hamid Pishdadian.

Improved PFC also increases internal electrical system capacity, since unconnected power increases losses in the electrical distribution system and limits capacity for expansion. The voltage drop at the point of use also is improved. Voltages below equipment rating reduce efficiency, increase current, and reduce the motor’s starting torque.

BOX: UL 508 INDUSTRIAL CONTROL EQUIPMENT

Requirements cover industrial control devices, and devices accessory thereto, for starting, stopping, regulating, controlling, or protecting electric motors. These requirements also cover industrial control devices or systems that store or process information and are provided with an output motor control function(s). This equipment is for use in ordinary locations in accordance with the National Electrical Code, NFPA 70.

These requirements cover devices rated 1500 volts or less. Industrial control equipment covered by these requirements is intended for use in an ambient temperature of 0 - 40°C (32 - 104°F), unless specifically indicated for use in other conditions.

A product that contains features, characteristics, components, materials, or systems new or different from those covered by the requirements in this standard, and that involves a risk of fire or of electric shock or injury to persons shall be evaluated using appropriate additional component and end-product requirements to maintain the safety level as originally anticipated by the standard. A product whose features, characteristics, components, materials, or systems conflict with specific provisions of this standard does not comply with this standard. Revised shall be proposed and adopted in conformance with the methods employed for development, revision, and implementation of this standard.