Power Management, Chapter 3: Power Supplies-Make or Buy?

This articles is part of the Power Management Series in the Power Management section of our Series Library.

Download this article as a .PDF eBook.

Power supplies are necessary in virtually every piece of electronic equipment. Therefore, equipment manufacturers are confronted with the task of deciding whether to make or buy a power supply for their system. DC power management employs a power supply that can either be bought or made by the equipment manufacturer. The make-or-buy decision for power supplies can have a major impact on the cost and time-to-market for the end-item electronic equipment.

The equipment manufacturer has several challenges to consider before making a power supply in-house:

- Can they make it cheaper than a purchased power supply?

- Is time-to-market a consideration?

- Are the necessary people and resources available to make the power supplies, including design and production facilities?

- Does the design and production include the time, costs, and fees associated with getting agency certifications specific to power supplies?

Unless the equipment manufacturer can meet these challenges, it most likely will buy the power supplies and then implement the power management subsystem. Among the reasons for an equipment manufacturer to make the power supply in-house are:

- They can’t install a commercial power supply because there is not enough room, such as in a battery-based portable system.

- They must meet unique safety and EMC (electromagnetic compatibility) requirements that are not available in commercial units, such as found in military and aerospace systems.

- They want the equipment to be proprietary.

- They think they can make it cheaper.

There are other factors to consider when deciding between making and buying the power supplies:

- Overall budget.

- Time-to-market for the end-item equipment.

- Finding and employing “safety critical” components for the power- supply section.

- Time, costs, and fees associated with getting agency certifications specific to power supplies.

- Will your competitors have an advantage if they purchase a technically superior standard power supply?

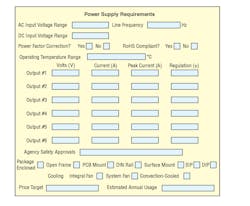

3-1. Power-supply requirements worksheet.

If the equipment manufacturer’s decision is to buy the power supplies, the first step is to find a manufacturer certified to meet the required reliability, safety, and EMC specifications. This usually means an investigation into the proposed manufacturer and development of the appropriate specification for the power supplies. Also, this usually requires a means for the equipment manufacturer to inspect the incoming power supply to ensure it meets its specifications. Plus, the equipment manufacturer may want to establish multiple sources to ensure delivery of enough products. In addition, the power-supply manufacturer should provide documentation and technical support, if it is required. The power-supply company should also be able to support the return of failed units.

Involve the power-supply manufacturer early on in the design stage for architectural, product, and cooling discussions. Traditionally, power supplies have been subject to the tailpipe syndrome (i.e., remembering them when the project is nearly complete and having little time to select them).

If the equipment manufacturer decides to make the power supplies, it will start with a paper design, followed by a prototype, design review, and then a decision on whether to go ahead with production. Given the go-ahead, the purchasing department can order all the components, which usually includes qualified components from qualified vendors. As long as there are no long lead-time components, production can start. Allow sufficient time for relevant safety agency approvals.

There are alternatives to making and manufacturing the power supplies. For example, one alternative is to subcontract the design phase. In addition, the production can also be subcontracted. The cost of subcontracting should be compared with doing everything in-house.

When the first units are completed they will have to be tested for safety, EMC, and reliability over the required temperature range. This depends on the appropriate standards that must be met, which might vary for some countries. If the manufacturer doesn’t have this facility in-house, the units can be sent to a testing laboratory.

The equipment manufacturer should check the supply’s reliability. They can send one or two supplies to a facility that performs HALT (Highly Accelerated Life Test) or ALT (Accelerated Life Test).

- HALT is the process of determining the reliability of a product by gradually increasing stresses until the product fails. This is usually performed on entire systems, but can be performed on individual assemblies as well.

- ALT is the process of determining the reliability of a product in a short period of time by accelerating stresses (usually temperature) on the product. This is also good for finding dominant failure mechanisms. ALTs are usually performed on individual assemblies rather than full systems.

- Calculate the electrolytic capacitor life using measured temperature data

The equipment manufacturer may also want to check each power supply by “burning them in.” This is usually done by powering each supply for a given period (for example, 24 hours) and then checking them to see if they are operating properly. Often, this is done by putting several supplies on a burn-in rack at the same time.

What OEM ac-dc power supplies can be purchased?

- AC adapters.

- Front-end power supplies for Distributed Power Architecture (DPA).

- Centralized power supplies (single- and multiple-output voltages).

- AC-DC brick power supplies.

- High-voltage power supplies.

What OEM dc-dc converters can be purchased?

- DC-DC brick dc-dc converters (single- and multiple-output voltages)

- Non-brick dc-dc converters (single- and multiple-output voltages).

- Encapsulated dc-dc converters (single- and multiple-output voltages).

- Bus dc-dc converters.

- Point-of-load (POL) converters (non-isolated).

- Power over Ethernet power (PoE) supplies.

- High-voltage dc-dc converters.

It is a good idea to select a power supply that provides a safety margin for the future. Too often, electronic systems expand from their initial requirements and need additional current, power, and sometimes even a new output voltage. A new output voltage requires an additional power supply or one with an adjustable output voltage, although most supplies can accommodate a 10% variation in output voltage.

The OEM power supply must provide the necessary output voltage, current, and power. With such a broad range of standard products, you should see what type of power supply can meet your requirements. One way to start is to understand the characteristics of the available power supplies. If you can’t find a standard supply to meet your requirements, you will probably need to buy a custom-designed supply that is more expensive than a standard unit. An economic alternative to a custom power supply is the wide range of “modular power supplies” on the market today that can be tailored to your needs without the NRE and delays associated with a custom design.

One of the best ways to find the optimum power supply for your application is to fill out a form similar to that in Fig. 3-1. This allows you to list your requirements and then leave it up to the power-supply vendor to give you the answer. The completed form also allows you to use the same information if you are looking for a second source.

Read more articles from the Power Management Series in the Power Management section of our Series Library.

Related Articles

1. Bonnie C. Baker, Tackling the Challenges of Power Dissipation, powerelectronics.com, April 2004.

2. David Morrison, Modeling DC-DC Converter Transient Response, powerelectronics.com, August 2004.

4. Tom Skopal, Power-Supply Failures Are Mostly Preventable, powerelectronics.com, August 2008.

7. Steve Sandler, When Bode Plots Fail Us, powerelectronics.com, May 2012.

9. Joe Chong, Managing Multiple Supply Voltages, powerelectronics.com, August 2004.

10. Brian Narveson, Why Is My DC-DC Converter Too Hot?, powerelectronics.com, June 2006.