This Week in PowerBites: EV Drivetrain MOSFETs, Hybrid Aircraft

>> Electronic Design Resources

.. >> Library: Article Series

.. .. >> Article Series: PowerBites

4th-Gen SiC MOSFETs Boast Ultra-Low On-Resistance, Target EV Drivetrains

With an eye on automotive powertrain applications, ROHM announced its fourth-generation AEC-Q101-qualified, 1200-V silicon-carbide (SiC) MOSFETs. They offer exceptionally low on-resistance that can improve the efficiencies of main drive inverters, as well as power supplies in industrial equipment. As electric vehicles (EVs) and plug-in hybrid EVs (PHEVs) face growing expectations to deliver the range and performance of their fossil-powered counterparts, their larger battery capacities and higher operating voltages make SiC power devices increasingly attractive for both traction drives and on-board charger systems.

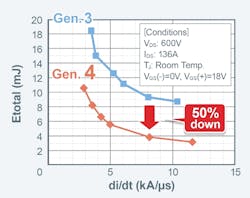

ROHM has been able to successfully improve the traditionally difficult tradeoff faced by SiC device manufacturers to strike a balance between a reducing a MOSFET's on-resistance and the expense of its short-circuit withstand. The new devices are fabricated using an improved double trench structure, which gives them 40% less on-resistance per unit area over conventional products without any sacrifice in short-circuit withstand time (see figure below).

The devices also enjoy significantly lower parasitic capacitance (which causes problems during switching). The reduced on-resistance, combined with their lower parasitic capacitance, makes it possible for designers to achieve applications with 50% lower switching losses that previous generations of SiC MOSFETs would permit.

Bare chip samples are available now; discrete packages will be offered in the future. Information about ROHM's third-generation devices is available at: https://www.rohm.com/products/sic-power-devices. For information on ROHM's fourth-generation devices, contact [email protected].

Web-Based Resources to Accelerate Development of Smart, Efficient Digital Power Solutions

STMicroelectronics has launched a web-based ecosystem to help designers build digital-power solutions using STM32 microcontrollers (MCUs). The site's resources focus on digital power supplies, an emerging class of devices that can optimize energy efficiency and capture rich data for diagnostics and safety. Applications include data centers, 5G infrastructure, smart lighting, and mobile devices.

Most of the materials and resources are available free on the STM32 D-Power website, which include the all-in-one STM32 digital-power Discovery Kits, dedicated power-supply boards, and embedded software components—software tools created by ST Authorized Partner Biricha Digital. It supports three levels of STM32 MCUs that combine the benefits of standard Arm Cortex-M cores with integrated features optimized for digital-power applications. The site offers documentation, evaluation kits, videos, and guides that cater to power-supply designers from beginner to expert.

Resources include:

- Tutorials, videos, application notes, and evaluation kits for digital power-supply and power-factor-correction (PFC) design.

- A software development kit (SDK) that includes ST-WDS power-supply design software and ST-PLD PFC design software , as well as embedded-software examples for buck/current-mode and buck/voltage-mode supplies.

- Evaluation boards with PFC in various topologies, such as totem-pole PFC and LLC resonant full-bridge, with power ratings from 500 W upwards.

- A free four-day hands-on workshop that shows how to build digital power supplies based on STMicro's STM32F334 and STM32G474 MCUs.

For more information, visit the STM32 D-Power website.

2020 IEEE IEDM to be Held Virtually (Virtual Mai Tais Optional)

Thanks to the global pandemic, it will be at least another year before semiconductor-savvy savants will be able to gather on the shores of Waikiki to ponder the future of electron devices. However, they will still be able to attend a virtual gathering of the 66th annual IEEE International Electron Devices Meeting (IEDM), scheduled for December 12-16, 2020.

Organized by the IEEE Electron Devices Society, this year's virtualized IEDM will offer both live and recorded sessions covering technological breakthroughs in semiconductor and electron device technology and discussions of the world’s best original work in all areas of microelectronics research and development.

Persistent rumors of a virtual cocktail hour for attendees that will offer unlimited virtual Mai-Tais and prizes for the best Aloha shirts at the gathering have yet to be confirmed…

More details about the 2020 IEDM will be announced in late summer. In the meantime, you can follow IEDM via social media:

- Twitter: www.ieee-iedm.org/twitter

- LinkedIn: www.ieee-iedm.org/linkedin

- Facebook: www.ieee-iedm.org/facebook

Super-Junction N-Channel MOSFET Family Now Includes 650-V Devices with Enhanced Efficiency

Toshiba Electronics Europe has introduced eight new super-junction N-channel power MOSFETs to its DTMOSVI series. The 650-V-rated devices all offer a 40% reduction in drain-source on-resistance × gate-drain charge (QGD) figure of merit (FoM) over Toshiba's previous generation of DTMOS devices. The new MOSFETs are targeted at switch-mode power supplies for a broad range of industrial equipment (including data-center infrastructure, backup power sources, and the power conditioners of photovoltaic generators). When used in these applications, the lower resistance translates into an efficiency of improvement of approximately 0.36%.

The TK110Z65Z, TK125V65Z, TK170V65Z, and TK210V65Z offer a Kelvin source pin for improved control and efficiency. The TK110N65Z and TK110Z65Z fit into TO-247 packages with 3/4 pins, while the TK110A65Z, TK155A65Z, and TK190A65Z come in fully isolated TO-220SIS packages. Finally, the TK125V65Z, TK170V65Z, and TK210V65Z are all housed in an 8- × 8-mm DFN package format for surface mounting. Click here for more information on Toshiba’s super-junction N-channel MOSFETs.

Smallest, Fastest Integrated Voltage Regulators Sampling Now

Empower Semiconductor’s EP70xx family of power-management ICs provides significant energy savings in data centers by offering dramatic improvements in point-of-load power efficiency, protection, and performance. Empower's EP70xx platform integrates a triple-output dc-dc power supply within a single 5- × 5-mm package, which can deliver up to 10X higher current density, 3X tighter accuracy during transients, and 1000X faster dynamic voltage scaling than leading competitors.

The EP70xx's digitally configurable hardware architecture simplifies the process of integrating dc-dc converters into a design by eliminating the need for input/output filter design, feedback resistors, or external loop-compensation components. They can be easily configured via its I3C/I2C port using the factory-supplied GUI. Once in service, its unique architecture allows the regulators to deliver peak efficiencies of up to 91% with a nearly flat efficiency curve up through 10 A of output current. The accelerated dynamic voltage scaling enables rapid, lossless processor state changes that reduce processor power consumption by 30% or more.

The EP70xx family comes to market with eight initial products: four triples, two duals, and two singles. Product samples, demo boards, and reference designs of the family with input voltages varying from 2.5 to 16 V are available immediately to qualified customers. Volume production is planned for Q4 2020. For more information on Empower's integrated voltage regulator (IVR) products, visit https://www.empowersemi.com/product-page-ivr/

Regenerative Power Supplies Bring Greater Efficiency to HEV/EV Battery and Electronics Testing

Keysight Technologies is expanding its RP7900 Series with two new bidirectional, regenerative dc power supplies. They offer integrated safety features and higher current outputs needed to test the larger batteries being used in the next generation of electric vehicles. The supplies’ unique regenerative design enables the energy normally consumed to be cleanly returned to the grid, saving costs associated with energy consumption and cooling.

By combining the seamless source and load functionality into a compact 3U-high package, Keysight's RP7900 Series of regenerative power supplies minimizes high-power test costs by shrinking floor-space usage, reducing heat dissipation and maintaining uptime. Available in two models—20 kW and up to 2,000 V—they’re part of the company's HEV/EV Power Converter Test Solutions, offering the following features and benefits:

- Two-quadrant, bidirectional sourcing and sinking capability allows for seamless, uninterrupted transitions between sourcing and sinking current without changing the power supply's output characteristics or introducing disruptive behaviors.

- Autoranging output improves flexibility over conventional power supplies due to an expanded power curve, which delivers more voltage and current combinations.

- Fast output speed, sub-millisecond command-processing time (≤1 ms), and output list for faster testing throughput.

- Simultaneous voltage and current measurement capabilities with high accuracy and resolution.

- Reduction in rack space requirements.

Pricing and availability: The RP7900 Series is available now, starting at USD $27,335. Additional information can be found at www.keysight.com/find/RP7900.

Hybrid Gas/Electric Aircraft Helps Pave the Way for Electric Aviation

Is the airline industry really ready to embrace electric propulsion? Five years ago, electric airliners were, at best, a technology for a far-off future. But now, a combination of growing environmental concerns, wildly fluctuating fuel prices, and steady improvements in propulsion technology have moved electric airliners much closer to our event horizons.

While electric propulsion still faces several major technical challenges before it's mature enough to use in big airliners, Ampaire is helping accelerate the trend by offering a so-called hybrid solution for electrifying existing airframes. A hybrid prototype, sporting one gasoline engine and one electric engine, has already been successfully tested and is providing valuable engineering data for Ampaire's upcoming products.

Credit: Ampaire

Based in Hawthorne, Calif., Ampaire is developing the Tailwind, a small, all-electric airliner, intended to help short-haul regional airlines reduce their operating costs by up to 70% and achieve a similar drop in their environmental footprints. The sleek composite-bodied nine-passenger craft uses a ducted pusher prop and appears to shares many characteristics with the Alice Commuter, being developed by Israeli-based eViation, scheduled to enter production in 2022.

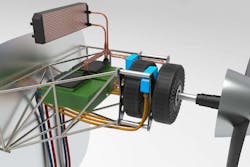

One of the critical elements in the airliner's development process is the power plant (see image below), which must be efficient, lightweight, easy to manufacture, and reliable—four seemingly orthogonal requirements. In designing a prototype of the motor and drive electronics, Ampaire's engineering team decided that the best way to test the system under real-world conditions would be to retrofit an existing twin-engine aircraft, replacing one of its gasoline-burning power plants with an electric motor.

They found an ideal candidate in Cessna's 337 Skymaster, a six-seat utility aircraft known as much for its unusual "push-pull" propeller configuration as its large cargo capacity and ease of operation. This allowed them to create an inline, parallel hybrid architecture in which the Skymaster's original gasoline engine remains in the rear of the aircraft, and Ampaire's electric-powered propeller replaces the front engine. According to Ampaire, this so-called hybrid system allows power to be dynamically shared across both propulsion systems to optimize speed, power, fuel consumption, or noise.

The power-delivery system for the Ampaire prototype plane consists of a high-voltage battery pack. Depending on its state of charge, the pack's output voltage can range between 500 and 738 V. Rather than use a separate battery to power the radios, instruments, and other avionics that require a 28-V supply, Ampaire's design team turned to Vicor, a power engineering and manufacturing company. Vicor developed a two-stage solution consisting of a fixed-ratio bus converter (BCM) to isolate and downconvert the high-voltage from the battery, followed by a low-voltage dc-dc converter to regulate the output of the bus converter to 28 V.

In addition to proving the technology, Ampaire's president believes that hybrid aircraft may be a large potential market for the company in the form of retrofit kits for existing multi-engine airframes. These could help dramatically reduce operating and maintenance costs.

Credit: Ampaire

This isn't the last you'll see of Ampaire's Tailwind in Electronic Design. We'll be taking a closer look at the airliner, and the technology behind it, in a feature about electric aircraft that’s planned for the fall. So be sure to stay tuned for that, and other "shocking" tales of electric airplanes here in Electronic Design's Power Management section!

>> Electronic Design Resources

.. >> Library: Article Series

.. .. >> Article Series: PowerBites