This Week in PowerBites: Current-Sensing Pro Tip Tutorial, Li-Ion Evolution

This article is part of the Power Management Series: This Week in PowerBites

Get Smart(er) on Current Sensing

Whether you're a seasoned analog designer or a digital expert who's just getting your toes wet in the deep waters of power electronics, you'll find something of value in Texas Instruments' latest eBook “Simplifying Current Sensing: How to design with current sense amplifiers.”

Although the book was created to showcase TI's devices, it provides clearly written product-independent information on the theory behind the most commonly used current- and power-sensing techniques and how they’re applied in specific use cases. Each application is accompanied by the theory behind it. This is followed by an example that lays out a circuit/function as a problem statement and provides a detailed outline of any challenges associated with that function.

The eBook is broken down into 5 chapters:

- Current-sensing overview: Integrated resistor sensors, BMS applications, multichannel applications, power and energy monitoring, and more

- Out-of-range current measurements: Detecting out-of-range conditions, high-side motor current monitoring and protection

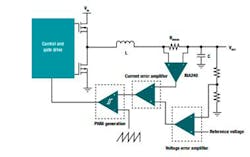

- Current sensing in switching systems: Precision in-line motor current measurements, high-side solenoid monitoring, current-mode control in switching supplies, and more

- Integrating the current-sensing signal chain: Integrating current-sensing elements (resistor, A/D), precision sensing with magnetic current sensors, and more

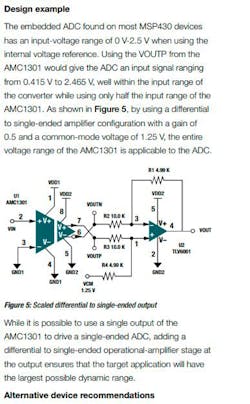

- Wide VIN and isolated current measurement: Interfacing differential output amplifiers to single-ended ADCs, extending the range of current-sense amplifiers, and more…

If you’re interested in this clear, concise, and practical discussion of some important and infrequently covered issues, you can download the eBook in .pdf format.

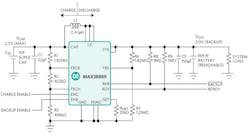

Compact Regulator Offers High Accuracy, Efficiency for Supercapacitor Backup Apps

Created to simplify backup power systems that use a supercapacitor or other energy sources, Maxim Integrated's Continua MAX38889 2.5- to 5.5-V, 3-A reversible buck/boost regulator delivers the best combination of efficiency, size, and accuracy currently available. It’s optimized for applications such as smart utility meters or automotive dashboard cameras, where a regulator operates in buck mode to charge a backup power source like a supercapacitor. When main power goes away, the regulator reverses direction automatically, boosting the supercapacitor voltage to power the system, until main power is restored.

The MAX38889 features 94% peak efficiency, 9% higher than the closest competitive solution, allowing it to support longer backup time. In addition, it delivers the industry’s tightest output regulation of 2.5% to support critical applications that demand high accuracy. On top of that, the device's compact form factor and high levels of integration enable a complete backup power solution that’s up to 64% smaller than the closest competitor (218 mm2 vs. 606 mm2), allowing designers to reduce component count, cut board space, and save BOM cost.

The MAX38889 is available at Maxim Integrated’s website for $2.36 (1000-up, FOB USA), or from authorized distributors. Its companion evaluation kit, the MAX38889EVKIT#, is available for $63.

To order the MAX38889 or learn more, visit https://bit.ly/MAX38889_Product.

GaN Adapter Board Expands Dynamic Power Analyzer/Double-Pulse Tester Capabilities

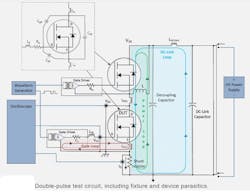

Keysight Technologies Inc. introduced a customized gallium-nitride (GaN) test board for its PD1500A dynamic power device analyzer/double-pulse tester that allows GaN devices to be characterized across their full frequency range. This enables Tier 1 and OEM power-converter designers to use the PD1500A's broad capabilities and high precision to reduce prototype cycles and shorten time-to-market of GaN-based designs.

Thanks to their superior efficiency, speed, voltage, and thermal performance, power devices fabricated in GaN and other wide-bandgap materials are being widely adopted for converters used throughout the transportation, renewable-energy, and industrial markets. This includes traction inverters, battery chargers, and renewable-energy systems. But, along with their improved performance, they possess several unique characteristics that must be fully characterized to ensure a successful design.

Keysight's PD1500A dynamic power device analyzer platform can already deliver consistent, reliable characterization of discrete silicon (Si) and silicon-carbide (SiC) based power devices. And with the introduction of this customized test board, its capabilities are now extended to GaN devices, which are expected to catch up with SiC's higher operating voltages (1.2 kV and higher), making them a potential choice for higher-power applications in e-Mobility.

For additional information, visit Customized GaN Solutions for Double-Pulse Test.

Chokes with Top Specs

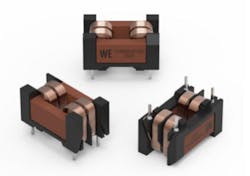

Würth Elektronik expanded its portfolio of common-mode chokes with two new models: the THT-mountable WE-FCLP for common-mode and differential-mode suppression, and the WE-CMDC SMT data-line and low-voltage common-mode choke. Both are available from stock without a minimum order quantity.

The WE-FCLP (shown above) has a compact design with a maximum height of 14.5 mm, yet achieves an inductance up to 100 mH. It’s able to suppress common-mode interference up to 85 dB, and thanks to its high leakage inductance, can be used not only for common-mode suppression but also for differential-mode suppression. WE-FCLP is suitable for applications like mains-powered LED drivers, electronic ballasts, switch-mode power supplies (SMPS), and mains filters. Full specifications and purchasing information can be obtained by clicking here.

WE-CMDC (shown above) is an AEC-Q200 Grade 1 qualified data-line common-mode choke. Measuring 11 × 12 × 6 mm, it’s also very compact. The choke has a current-carrying capacity up to 8 A and is available with high impedances of 700, 1,000, and 1,500 Ω. In addition to data and signal lines, applications include low-voltage dc power supplies and dc-dc converters. Full specifications and purchasing information can be obtained by clicking here.

Single-Channel Gate-Driver ICs Integrate Galvanic Isolation in Mil 8-Pin DSO Package

The EiceDRIVER 1EDB family of single-channel gate-driver ICs from Infineon Technologies includes four parts (1EDB6275F, 1EDB7275F, 1EDB8275F and 1EDB9275F) and is optimized for both high/low-side applications. Their simplified 8-pin MIL-grade package can solve PCB-layout problems common in high-power applications such as server and telecom SMPS as well as uninterruptible power supply (UPS) systems.

Due to their increased power-density need, EV-charging designs often require fast-switching power MOSFETs. Photovoltaic inverters take advantage of SiC MOSFETs as they enable both lower switching losses and a significant step forward in power density.

The new 1EDB family addresses all of those applications, delivering high system efficiency and robust and safe system operation. Their galvanic input-to-output isolation of 3 kVrms (UL 1577) ensures rugged ground-loop separation. Their common-mode transient immunity (CMTI) exceeds 300 V/ns, suiting these devices for hard-switching applications and enabling numerous topologies.

All products come with separate and very low ohmic (0.95 Ω) source and (0.48 Ω) sink outputs for ease of design, offering typical drive strengths of 5.4-Apeak source and 9.8-Apeak sink. This feature plays a vital role in reducing the switching losses of power MOSFETs. The input-to-output propagation delay accuracy is ±4 ns helping to cut switching losses, which is essential in fast-switching applications. The typical output-stage clamping speed is as short as 20 ns and supports functionally safe system operation, especially during startup.

EiceDRIVERs 1EDB7275F and 1EDB8275F are available in 150-mil 8-pin DSO packages and can be ordered now. Variants 1EDB6275F and 1EDB9275F will follow shortly. Further information can be found at www.infineon.com/1EDB.

Evolution, Not Revolution, May be the Future for Li-Ion Batteries—an ED Exclusive

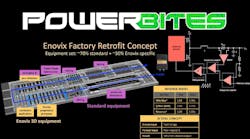

Enovix, a company focused on developing advanced battery technologies, appears to be coming closer to realizing its vision of using existing manufacturing facilities to produce lithium-ion cells with more durable silicon-based anodes. The company claims that its anode structure, which they refer to as 3D Silicon, will enable the cells to have higher power densities, deliver significantly more charge/discharge cycles, and cost less per watt-hour than today's commercially available products.

Enovix has already shared an overview of its 3D Silicon technology as part of a white paper that outlines plans to produce its new battery at scale, but many details remained unclear. Since then, Harrold Rust, the company's CEO and co-founder, revealed some important new details about the technology during a recent interview with Electronic Design. They will be revealed in an upcoming feature that will be posted in a few weeks, but PowerBites is pleased to give you a sneak peek at a few excerpts from the full story:

Can you tell us about some of the challenges Enovix faced in trying to create Li-ion products with silicon electrodes that are long-lived and can be produced by upgrading existing manufacturing plants?

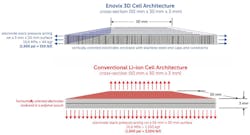

The first part of this question is best addressed with this illustrated comparison between two 50- × 30- × 3-mm cells: one of conventional Li-ion cell architecture and another of Enovix 3D cell architecture.

As shown in the conventional Li-ion cell architecture, electrodes are wound or stacked in parallel to the (red) face of the battery. In this architecture, which uses a graphite anode, lithium atoms slip into the vacant spaces between the graphite layers, forming LiC6. As a result, the graphite anode experiences modest swelling and contraction during charge/discharge cycling (<10%). In a silicon anode, however, lithium atoms form an Li15Si4 lithium-silicon alloy that does not have such vacant spaces.

While this alloying process results in an increased ability to store lithium, it can also cause significant expansion of the anode material during charging, creating high pressure within the battery (10.4 MPa or 1,500 psi in an Enovix battery). If silicon were to be simply substituted for the carbon anode in a conventional battery architecture, the pressure generated by the anode's swelling would act on the large face of the battery (red), requiring a force as large as 1,550 kgf, or 3,500 lbf (about the weight of a mid-size automobile), to contain it.

To reduce the pressure created by the anode's expansion, the Enovix 3D cell's electrodes are laser-cut into 3- × 30-mm strips and stacked side-by-side to a width of 50 mm. Rather than having long electrodes that run parallel to the face of the battery, Enovix cells have many small electrodes that are orthogonal to the largest face of the battery.

This seemingly small difference produces huge benefits. When silicon anodes are used in the Enovix 3D cell architecture, they do not face the largest side of the battery; instead the anodes face a short (3 × 30 mm) side of the battery (blue). Because the anode faces are small in area, this same 10.4 MPa or 1,500 psi pressure requires a force of only 94 kgf or 210 lbf to contain the expansion.

Evonix has developed a stainless-steel constraint system that surrounds the cell and limits the battery's tendency to grow in size due to swelling. As a result, the typical swelling of an Enovix 3D cell after 500 cycles is less than 2%. In addition, the constraint system keeps the anode and cathode materials under constant compression, which maintains a near-optimum particle-to-particle connection.

Can you tell our readers a little about the electrical characteristics these batteries will have, i.e. charge and discharge rates, battery-management requirements, and how these batteries compare to existing Li-ion cells in terms of safety, cooling requirements, and potential for thermal runaway?

Enovix's present generation of 3D silicon batteries are designed for high energy and have similar charge/discharge and battery-management requirements as a standard Li-ion battery. In addition, they offer several advantages, including excellent thermal dissipation due to the parallel configuration of the thermally conductive electrode current collectors (highly conductive metals), which are bonded to the front and back face of the constraint system.

This configuration, with the stainless-steel constraint serving double-duty as a heatsink, allows the system to rapidly conduct heat out of the cell. Additionally, the stainless-steel constraint provides an added layer of protection from mechanical shock and puncture

To be continued...

In our upcoming feature, Enovix shares the specifications on its initial product line (hint: roughly 30% more capacity and significantly more duty cycles) and what will go into retrofitting existing Li-ion manufacturing facilities to produce its 3D silicon batteries.

Read more from the Power Management Series: This Week in PowerBites