Increase Reliability in Harsh Environment Apps with Automotive-Grade Fuses

What you’ll learn:

- Advances engineered into AEC-200-compliant SMD fuses.

- Fuse solutions that quickly isolate overcurrent faults to prevent damage to adjacent circuits.

- Fuse solutions that minimize nuisance tripping due to ambient temperature or inrush current to ensure the system stays online.

As electronic systems and applications have become more interdependent, overcurrent faults must be quickly isolated to prevent damage to adjacent circuits and systems. At the same time, nuisance tripping due to ambient temperature, inrush current, or other events that pose no risk to the system must be minimized to ensure the integrated system stays online.

Connected next-generation applications such as IoT and smart-sensor-based designs can be particularly vulnerable to overcurrent events that lead to failure of one or more devices. In turn, it reduces network reliability.

Many of these highly integrated and interdependent applications are systems that need to operate in severe environments, making dependable circuit protection an important part of these designs to maintain reliability. A primary example is the increasingly integrated electronics in automotive systems, which are commonly subjected to wide temperature variations.

Designers also need to keep in mind the stringent reliability standards for vehicle applications. These include engine controls, battery-management systems (BMS), and comfort/convenience features where overcurrent protection solutions are required to help meet these specifications.

Meeting Certain Harsh Environment Needs

One major factor influencing hybrid- and electric-vehicle market growth is the increasing number of electronic components used to support enhanced performance and comfort features. This, of course, corresponds to an increase in the number of potential fault conditions that these applications may experience.

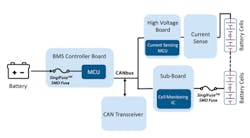

The rise in possible fault conditions has prompted designers of these emerging high-energy systems to look for circuit-protection components that are able to protect multiple elements of the design. For instance, overcurrent protection is necessary in a BMS design for the main control power input, slave-control monitor lines, and cell balance lines, as well as in the battery module and connection board.

For overcurrent threats caused by a transitory fault condition, which can cause serious circuit or system damage, fuses are an excellent choice. The trend to make all embedded electronics smaller while adding more features has led to an increased demand for space-saving surface-mount (SMD) fuses that can be easily mounted to a PCB. Even better news for automotive-system designers is that increasingly advanced AEC-Q200-equivalent compliant fuses are now available, providing higher reliability for operating in harsh environmental conditions. But what does it take for a fuse to be automotive grade?

Why Automotive Grade Makes a Difference

The standards for designating a component as “automotive grade” can vary by manufacturer. In general, automotive-grade components feature the use of superior raw materials along with a robust design, tight production control, and strict quality compliance. This can make a difference for components used in harsh environments.

That’s why for Bourns, its automotive-grade fuses must meet a number of heightened criteria, including being manufactured in facilities that are fully certified to IATF 16949. They also must be tested and qualified according to an AEC-Q200-equivalent product validation standard for passive components. These measures have been put in place to help ensure that any new automotive-grade product or new process development meets or exceeds the requirements established in the latest Automotive Industry Action Group (AIAG) revision of the Advanced Product Quality Planning (APQP) process.

Advanced Fuse Design Techniques

To reliably withstand a surge within the device’s rated specifications, the construction of an SMD fuse is important. One effective approach can be found in Bourns’ PCB wire core design that delivers enhanced voltage- and current-handling capabilities and boosts precision of hot-spot control along the fuse element.

This SMD fuse design also improves arcing suppression and inrush current withstand capability and offers superior structural integrity when blown compared to older typical ceramic-tube fuse designs. The precision fusing characteristics of the PCB wire core fuse design support a wide range of voltage, current, and breaking capacity ratings to help designers meet unique application-specific overcurrent-protection requirements.

The company also has developed a multilayer ceramic design that enables enhanced voltage- and current-handling capabilities, too. The new SMD fuse models come in compact 1206 and 0603 package sizes and feature high inrush current withstand capabilities and time-lag fusing speeds.

Considerations in Specifying Fuses

Because it’s common for certain automotive applications to experience startup pulses, designers typically specify fuses for these designs based on their inrush current withstand requirements. These designs benefit from fuses with enhanced inrush handling capabilities, which allow the fuses to operate reliably in inrush conditions without nuisance tripping and still protect against unwanted sustained overcurrent conditions. It’s also an important consideration to determine the expected duration of a condition when specifying the fuse type.

Other key considerations in automotive-grade fuse selection are current and voltage ratings and fusing speed. Optimal automotive-grade SMD fuse portfolios offer rated currents from 0.5 to 20 A, with a wide range of rated voltages from 24 to 250 V and available package sizes that range from EIA 2410 down to 0603.

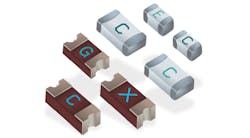

When selecting a fuse based on fusing speed requirements, it’s recommended to look for a fuse supplier with multiple options, including (at a minimum) fast-acting, slow blow, and high inrush withstand (Fig. 1). A good rule of thumb is that fast-acting fuses react quickly to an overcurrent condition compared to a slow-blow fuse that will endure short-duration spikes such as those that tend to occur during the initial power up of electronics.

Slow-blow fuses are designed to trip only when the spike is presented long enough to be a continual overload or short circuit. Specifying a slow-blow fuse in place of a fast-acting fuse needs to be carefully considered since it may not open quickly enough to protect sensitive electronics from an overcurrent threat.

Putting Automotive-Grade SMD Fuses to Work

With their advanced features, various voltage and current ratings, assortment of fusing speeds, rugged construction, and wide temperature range operation, the new generation of automotive-grade SMD fuses are capable of meeting specific protection requirements.

For example, in an on-board charger (OBC) application, an SMD fuse can be used as primary overcurrent protection between the power grid and the dc-dc converter (Fig. 2). Or, for USB I/O port protection, fuses with optimized voltage and current ratings are ideal for automotive systems that utilize dc-dc converters, such as 48 V to 12 V. And, in a BMS design, SMD fuses can be utilized as both primary overcurrent protection on the BMS controller board and for battery-cell overcurrent protection.

There’s no reason that the advantages of automotive-grade SMD fuses need to be limited to vehicle applications. These high-reliability overcurrent-protection solutions also will work well for telecom and networking infrastructure equipment, cloud computing and storage systems, high-end consumer electronics and smart appliances, and industrial IoT and robotics.

A final helpful tip is that product safety standards such as UL 9540 for energy-storage systems (ESS) now require overcurrent protection for battery-powered devices, their associated chargers, and UL power supplies. Therefore, many new consumer and industrial electronic designs also can leverage the benefits of secondary overcurrent protection provided by SMD fuses.